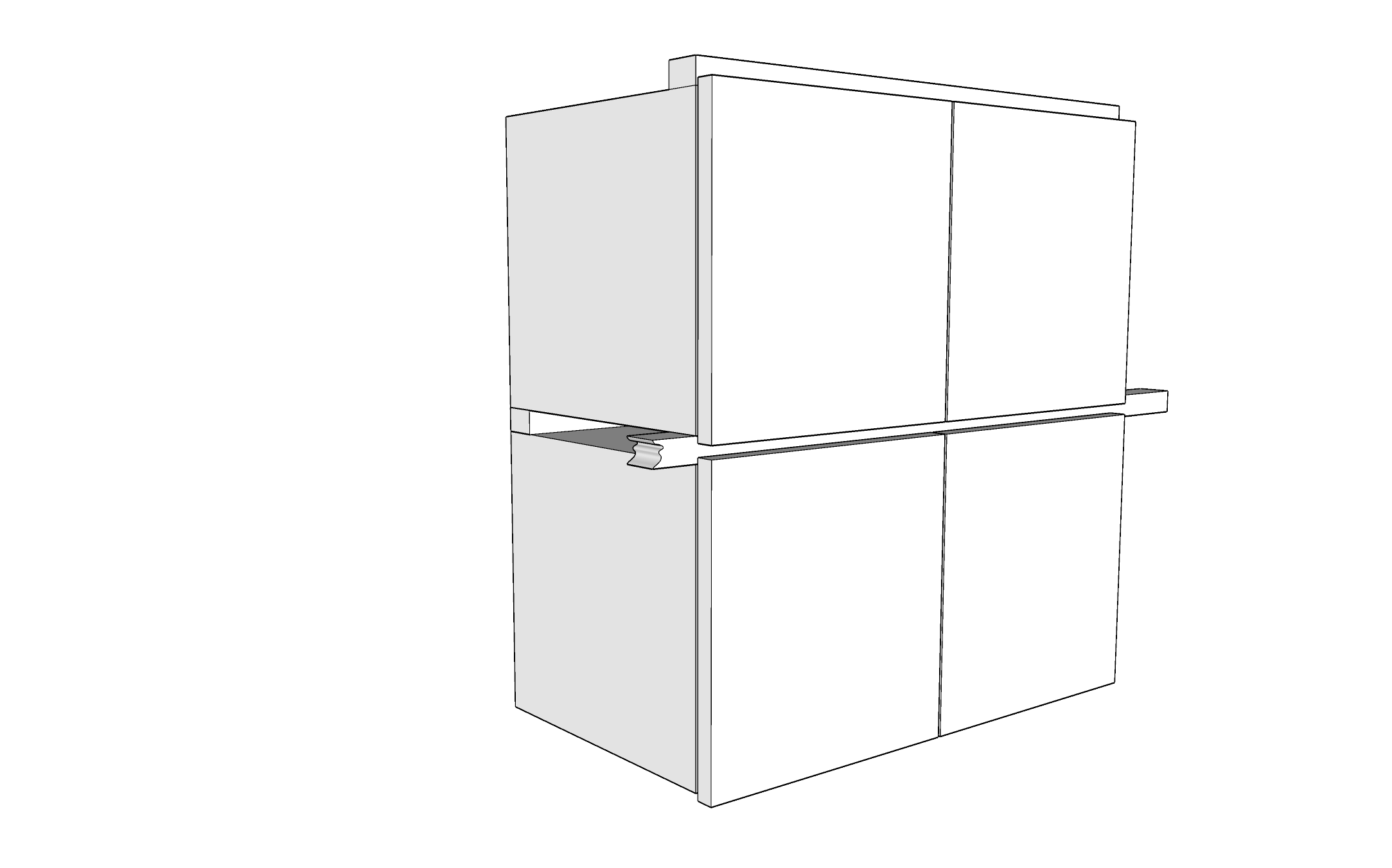

Ok, here's my problem. I'm a woodworker with many years experience making custom furniture. I've taken a job for a whole house of cabinets. I've already completed the vanities, utility cabinets, etc. The plans call for floor to ceiling cabinets across a whole wall, no counter top, just cabinets and a refrigerator. and they are the FULL DEPT OF THE FRIDGE (approx 28" deep), (see pic I made from Cabinet Planner software, which may not be the final design). The wall is 156" (13 ft) by 10 ft. tall.

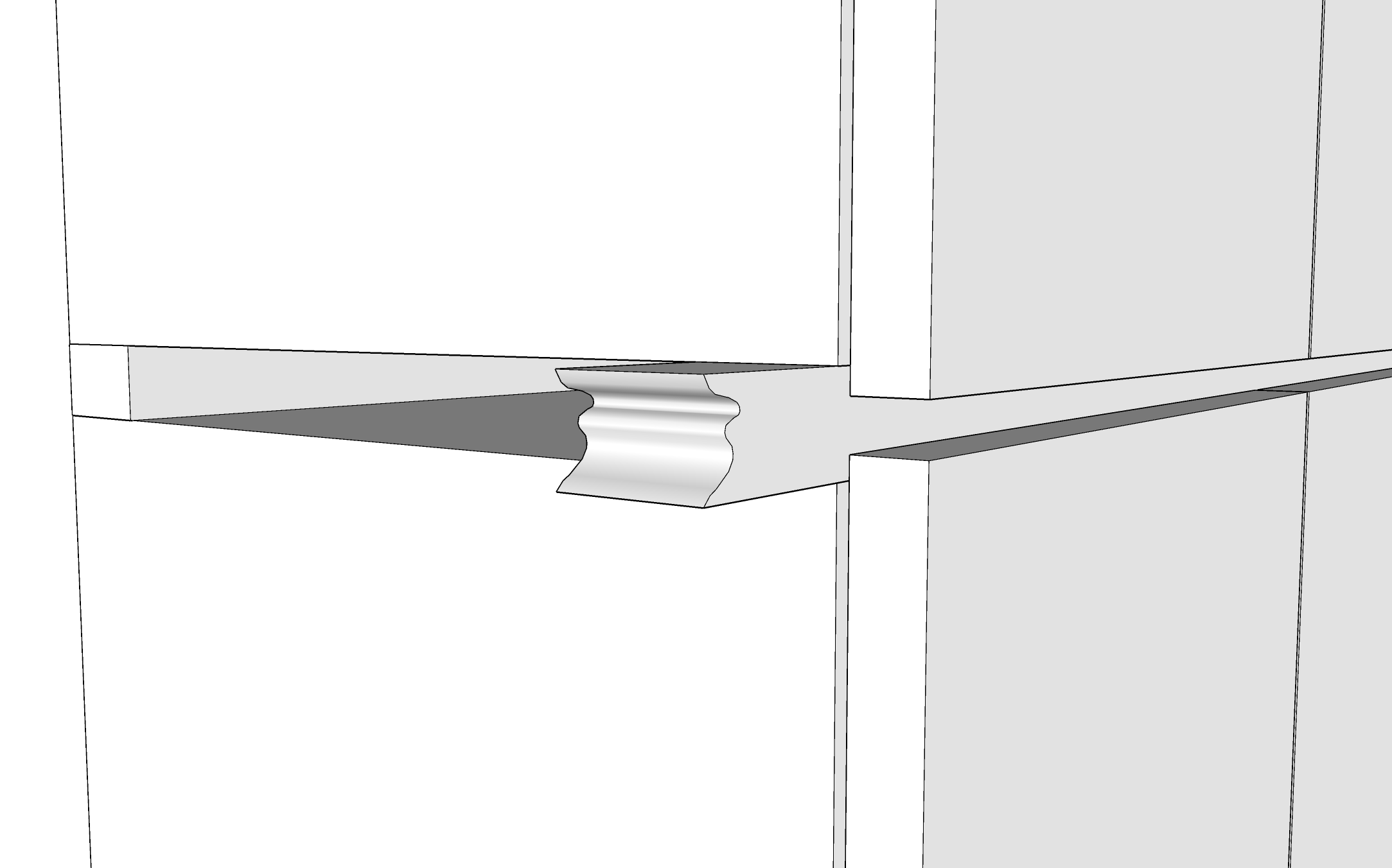

So, how do you join the faceframes for a seamless (or near seamless) monolith look. I plan to spray all cabinets with a pigmented catalyzed lacquer, so I prefer to do it all in the shop.

Some specific questions:

- do you use narrow FF at the joints?

- do you ease the edge (slight grove) at the joints rather than trying to hide them.

- how would you build the boxes, i.e., I was thinking about 4 tall vertical cabinets 28"-30" wide and one over the fridge, (30" x 115" x 28" deep would be some large cumbersome cabinets to build, finish, haul, and install) or how could I make multiple stacked boxes, etc.,

I'd appreciate any help I can get, and especially like to see pictures of your work for similar projects, and some close ups of joints.

Many thanks,

Dave B.