Question

I used compact one piece hinges from Grass for years, and then Dennis Bean got me switched over to Salice hinges, which I really like. Baer sent me a hinge machine with the condition that I buy my hinges from them - no problem with that either. Now Baer is carrying Blum hinges and not the Salice hinges, so looks like I need to find yet another hinge.

This got me to thinking. We have always put the doors and drawers on in the shop, but I wondered what it would be like using a two piece hinge and installing the cabinets and then snapping the door on at the end and adjusting? My Baer rep sent me a couple Blum hinges to look at, but they have tabs on the back of the mounting plate for 3/4'' face frame and my material is 13/16, so they won't fit, and I'm not interested in planing it down. From Baer I can use Blum, and Grass now has a few models with the Blum bore pattern. Those are my options. Do any of you use the two piece, like I mentioned above, and how does it work out?

Forum Responses

(Cabinetmaking Forum)

From contributor I:

If you like the Blum compact, you can order them in an edge mount. Then you can use whatever thickness face frame you want.

Salice also offers a broad selection with regard to degree opening and integrated soft close. They also offer the Salice undermounts and I like to keep all hardware with one brand and one supplier.

They allow us to bore the doors and put them on a cart, either finished or unfinished, and stretch wrap them and roll them into the trailer and into the house while on the cart. We no longer have to worry about transit damage or scratching the finish with the hinges or wasting time removing the doors at the jobsite and then reinstalling.

On the west coast, for example, you canít give away compact hinges, while in Michigan, that is what everyone uses (price is big in MI). For the most part, large cabinet manufacturers use only compact style hinges. Take a walk through the Home Depot kitchen department. In general, the custom shops I know want to distance themselves aesthetically as much as possible from a Lowes lookalike cabinet.

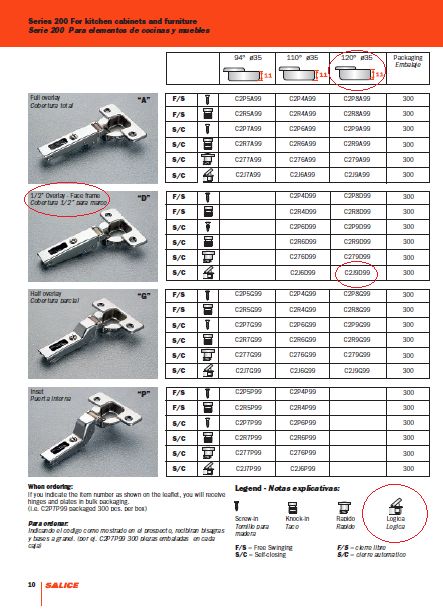

There are many advantages with 2 piece hinges. As others have mentioned, the gap behind the door is practically eliminated. With 2 piece hinges you have the ability to offer doors with very small gaps (1/8Ē) between doors. With 2 piece hinges the option to offer wider openings is possible. You have the availability of 110 degree, 120 degree and 165 degree openings. I am certain that having 2 piece clip-on/clip-off hinges offers some real advantages at install time. As mentioned above, the 2 piece system gives the options of Rapido or Logica as a means to attach the hinge to the door. And cabinetmakers that offer both overlay and inset doors find the 2 piece system advantageous. You canít do an inset door with compact hinges.

Contributor J, you have stirred my interest on your install method. So how does this Logica hinge attach to the door? Shrink wrapping the doors to a cart and wheeling it sounds like a breeze. But my concern on that is going up steps, onto porches, rough terrain, etc. I think as far as transporting, carrying cabinets into the house, and installing, it's a no brainer that it would be easier and faster with the doors off. Then again, you have to clip all the doors on when you get done, but that wouldn't take too long. Could you explain more about your process and how that hinge works?

How wide do you make your face frame and what overlay? I've always made everything 2'' wide with 1/2 overlay. I have often thought it would look better to have not as much frame showing, though. Maybe, instead of cutting the face frame down, it might be better to just get a bigger overlay hinge?

I build frameless, so no face frame to deal with.

Installing the hinges at the shop versus job is a wash. I'm assuming you have to remove the doors prior to installing the cabinets anyway, so that is one step saved and makes loading, unloading, delivering and installing the boxes easier.

I make use of my 12' aluminum truck ramp to deal with rough terrain and trashy jobsites. Just back up within reach and drop the ramp over the holes and job trash and straight through the entry door.

Doors and drawers never go on the cabinet until after the cases are installed. I install the hinges just prior to clipping the doors on. Seems it would be double or triple the work to install the doors, only to remove and reinstall them at the job. Won't need to stretch wrap the boxes either, just make sure they are packed in to prevent shifting around.

Cost difference is very minimal, basically the difference is the cost of the mounting plate. I buy the plate (box mount frameless) with the euroscrews preinstalled. I'm sure the face frame plate would cost a little more.

I focus more on the benefits (labor and frustration savings) than the minimal cost to upgrade to tool-less install and cam adjustments versus loosening and tightening screws, and going back to service call a hinge screw that has worked loose.

I'd suggest contacting Hafele and getting in contact with your outside sales rep. Great company to do business with. Dennis has also a great technical resource, and sends me those neat Salice screwdrivers that I like, and maybe some tee shirts (large) and ball caps (average sized head) :^)

To the original questioner: here is a page from our catalog showing the opening angle possibilities. Here you see the options of a 94 degree opening hinge, a 110 degree opening hinge or a 120 degree opening hinge. I have circled the 120 degree, 1/2" overlay Logica hinge (like contributor J uses). There is also the possibility to use the 165 degree hinge.

One additional benefit of the 2 piece system is the possibility of using thicker doors which are popular right now. With a compact hinge, 3/4" is the thickest door possible. If using 2 piece hinges the possibility exists to use doors up to 1-1/4" thick.

I do have a concern - I've always used an 1/8'' thick foam bumper for my doors. Never liked the poly or felt ones. The ones I use are really soft and since the compact hinge holds the door away from the frame, the 1/8'' thick bumper sort of evened that out. The door shuts much quieter with them than they do with the poly ones. I'd like to continue to use these bumpers, but if the two piece hinge lets the space between the frame and the back of the door be only about 1/16'', then I wonder if the 1/8 bumper might be too thick? I really can't see this being an issue, but I'm wondering if it might look odd?

I got in a pair of Silentia 45 degree for an upper angled cab and to be honest the closing was a lot slower than expected. This was on a 16"w x 36 7/16"h RP Door. I wound up disabling the soft close. Considering going the Silentia option to eliminate the bumpers altogether.