Bar Top Wood Movement Issues Explained

Yet another discussion of the reasons that large table or bar-top glue-ups tend to self-destruct. August 22, 2014

Question (WOODWEB Member) :

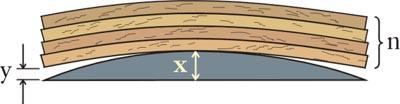

A bar top is to be glued up out of kiln dried walnut. This will be mostly flat sawn, face laminated. The length if the boards will be perpendicular to the length of the glue up. The entire event will be a large oval with about 100 foot circumference. This will be going from northern Montana to Las Vegas. What are the potential problems regarding future movement of the wood? 1

Forum Responses

(Architectural Woodworking Forum)

From contributor K:

According to the WOODWEB Shrinkage Calculator, 100 feet of edge glued flatsawn walnut will move almost seven inches with a two point change in moisture content, which isn't that great a change. (If you are in fact face gluing your lumber to show edge grain, the movement will be less.) In either case, you will have to devise a support system that both keeps it flat and allows it to move. If your kiln dried lumber is at 6-7% and is going to an air conditioned bar, there may be relatively little dimensional change, but it still must be anticipated and designed in.

From contributor M:

Something's missing. Are you edge gluing some boards together and then cutting out an oval (in plain-view) like a big table? Or are you gluing together tapered pieces to form a bar top in the shape of an oval (hollow in the middle where the bartender is)? Two different problems, with different considerations, however the point remains that you won't get away with pretending that the wood won't move.

From Carl Hagstrom, Systems Administrator at WOODWEB

Using WOODWEB's Wood Shrinkage Calculator, you can accurately predict anticipated movement. If you enter walnut as the species, choose flatsawn for the type of lumber, enter 12 inches for the width, and use a moisture content range of 4% (a realistic value for a building that does not have humidity control), you'll observe that the result is 1/8th of an inch.

Since the rate of movement is linear (each foot in width will move 1/8 inch), you can multiply the 1/8 value by the number of feet to get an accurate movement value. A circle with a circumference of 100 feet would have a diameter of roughly 32 feet - is this really the cross grain length of what you are considering? The resulting movement would be 32x1/8, or 4 inches. I think a drawing or sketch would be a big help in understanding your project. Follow the link below, and choose the "Wood Shrinkage Calculator" to plug in the numbers. WOODWEB's calculator page has many different calculators for woodworkers.

WOODWEB's Calculators page

From Contributor O:

"The length of the boards will be perpendicular to the length of the glue up.” I am reading this as a radial grain orientation. Large oval shape, with the grain direction radiating from a common center point. If this is correct, then that will be a 100' wide glue up. Applying Carl's numbers from the Shrinkulator, then there could be 12.5" of seasonal movement. Any bar rail will restrict movement, as well as fastenings to casework. I see this as a job for shop veneers pressed onto stable board.

From the original questioner:

Let me re-define. Picture a big oval bar with a bar tender standing inside the oval. Not a solid oval. Picture this big oval bar with the grain going the wrong way. The tangential bias is the thickness, the radial bias is the length.

From Carl Hagstrom, Systems Administrator at WOODWEB

My understanding is that each board will expand/contract according to calculated values. If you add up the widths of the individual boards that comprise the length of the bar, that will, in essence, be the width effected.

From contributor M:

I don't understand your last sentence. So far, we're solid on the oval doughnut shape, but still don't have a grain orientation. Is it:

1: Every board runs across the bar top so that the customer is facing end-grain and the bartender is facing end-grain. This is what is called a radial orientation above.

2: All boards running in the same direction, as if you first glued up that solid oval table, then cut out the middle?

From contributor R:

If I understand you correctly, given the orientation of the boards, a hole in the middle does not matter as you will have a lot of movement. I will vote with Contributor O on this - veneer on a stable substrate.

From contributor J:

Wood movement is across the grain, and is different for the quartered and flatsawn dimension. Assume Contributor O is right about the expansion factor (I haven't looked it up). If you take the 4% figure yielding 1/8" of movement per foot, times 100 feet circumference, you get a change of 12 1/2" in circumference. That translates to 4" diameter, or 2" of radius, in a radially glued top.

Ask yourself, will it matter if the top sticks out 2" more at some times than at others? Both front and back, because it will be moving in and out. How will you secure the top to the base with that much movement? How will the bar rail and setup rail (if any) accommodate it? Don't get me wrong, if you can pull this off you can make something that looks fantastic. You just have some big technical challenges. Looking at a project like this, I think back to the old days when we mined obelisks in Egypt. We'd drill a row of holes in the granite, pound in wood and then pour water on it. Pop goes the obelisk— not much can keep wood from expanding when it gets wet.