Question

Many customers want glazed doors. Can you give me the basics on glazing?

Forum Responses

(Finishing Forum)

From contributor A:

Glazing is an easy finishing technique to learn. In my opinion, it is the most versatile technique in finishing. Glazing is used on sealed raw woods, on stains, toners, and shading stains.

It is the key to faux and fantasy finishes, and can be used anywhere during the finishing process to add color or effects.

On a stained and sealed piece of wood, do this... Lightly sand with 320 (just to rough it up). Mix up a stain color that is darker that the stained piece you just sanded. Put a little clear Watco oil in it, or use boiled linseed oil. (That will let you fool around with it and slows down the flash time.) Dip a cotton rag into that stain mixture (you want a damp cloth, but not one dripping wet). Evenly wipe it on your sample piece. Now comes the easy partů Get a very wide pure bristle brush, and brush with vigor. First against the grain and then with the grain. Keep the brush dry as you are doing this. Soon you will have a glazed piece of wood that's ready for finishing steps. That's how I learned to glaze. Start small and practice, practice, practice. Many moons later I am able to do 4x8 sheets in the same manner as the smaller pieces. This phase of finishing is easy to do, but it takes practice to get even, streak-free results. Hang in there and have fun.

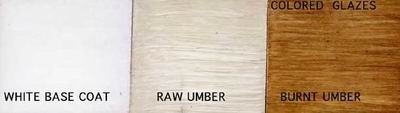

Another technique is to leave brush lines on a background of different colored stains, toners, and an opaque base coat.

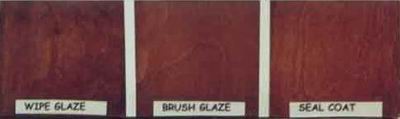

Here are some photos showing both of these glazing techniques. The photo where the glaze is completely brushed out is referred to as a factory finish, although many finishing shops use this same technique.