Biscuit Fit Problems

Swelling due to moisture, or narrowing of the slot due to cutter sharpening, are possible reasons why biscuits don't fit. November 13, 2009

Question

We use a lot of biscuits for casework but have a terrible time with inconsistent thicknesses. We have tried different brands, but no help. We have tried to keep them dry, but that doesn't help. Does anyone have a good method or ideas on how to size these things? The biscuits work best for what we do and if we could solve this problem, it would make life a lot easier.

Forum Responses

(Cabinetmaking Forum)

From contributor B:

Bake a few in the toaster oven. Low heat, 20 minutes. After cooling, store in a Ziploc. Or in the shop, a handful under a painter's lamp works well.

From contributor J:

Lamello brand are the most consistent that I've found. Haven't had much trouble with them at all. I did make a little sanding block with a couple screws sticking out the bottom to size a thick one. You could make a little plywood box with a light bulb in it to keep them real dry.

From contributor P:

The only way to solve your problem is stop using biscuits and switch to Dominos. I've been using one for the last two years and have never had even one not fit.

From contributor E:

If you're using a lot, it may not be worth your while, but what I've done in the past is put all the thick ones to the side. Once I have a bunch, I throw them in the microwave for a little while. Not totally efficient, only get about 50-60% to shrink enough, but it helps.

From contributor T:

I resort to smashing them with a hammer.

From contributor A:

I use many biscuits. Lamello brand are the best, but they too swell. I put thirty or so on a paper plate and put in the microwave for 90 seconds.

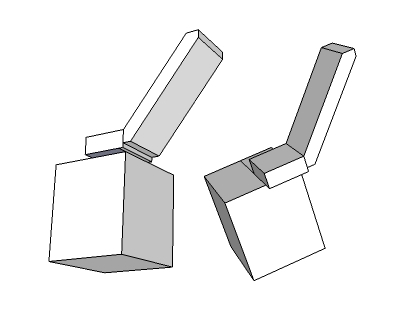

I just saw a press on eBay that looks interesting.

From contributor D:

This is a battle we at Lamello have been fighting for many years. Some woodworkers have gotten frustrated with biscuit joinery because of inconsistencies in slot tolerance, alignment, etc. We'd argue that the inconsistencies started arising when the lower quality biscuit joiners arrived on the market. So the problem may very well not be your biscuits. It may be your machine. If you're using a Lamello machine and Lamello biscuits, you should almost never have a problem (our biscuit tolerance is 1 of 1,300 won't fit).

One exception you may not have considered yet would be if you've sharpened your cutter several times, it may have shrunk enough in kerf that your slot is consistently undersized. Side clearances are designed into all cutters so all cutters shrink slightly in kerf each time you sharpen them.

To deal with this problem, Lamello cutters are engineered to start slightly oversized and get to slightly undersized as they are sharpened so you get a full life out of the carbide. Lamello also makes an insert cutter that you never sharpen; you simply replace the inserts.

And of course as the other forum members mention, your biscuits could be swelling in the box. But we've found that relative humidity has to be very high before a Lamello biscuit will start to swell.

From contributor G:

Before spending $200+ on a biscuit press, try a pasta machine (also available at craft stores for pressing polymer clay).

From contributor R:

As already mentioned, the Domino jointer is superior in both precision and strength to the Lamello biscuits. Make the switch; you will not look back.

From contributor O:

I use only Lamello plates and store the open box in resealable plastic containers with a package of desiccant. Desiccant is sold in little packages that can be reactivated in the oven or in bulk for refrigeration dryers. Unopened boxes of plates I store near the ceiling. Lamello has by far the most consistent product Ė if you donít count the miscuts that look like somebody has been taking bites out of them.

From contributor M:

Which brand of biscuit joiner do you use? I bought the newer style Porter Cable when it was first available about 10 years ago. The cutter was too small. I bought a Dewalt/Elu replacement. The cutter was actually wider and the biscuits mostly fit. Biscuit joiner cutters should be thought of as disposable.

From contributor Y:

To deal with expansion due to humidity, I put the biscuits in a jig and hit it with a sander for a few seconds; problem solved. The jig is a piece of MDF with the shape of a biscuit cut out in the center, about 1/8" deep. It holds it in place while the sander, with 100 grit paper, resizes the biscuit.

From contributor T:

I agree that the Lamello is the superior machine, and their biscuits are better, but find the "1 out of 1300 won't fit" absolutely hilarious. Here in Florida it's less than half, and I run AC 24/7. As noted above, the microwave helps, but once they swell they don't always go back. I believe most swelling comes from the shipping stage. You'd think Lamello could at least shrink wrap in plastic like their 1/2 priced competition does.

As for the Domino, a great machine also, but not for joining wide boards in sheet stock. The registration pin is not accurate enough to be consistent. I know you can set the hole to be bigger, but then you have to go by marked lines. Might as well use biscuits as it's faster and has the built in slop factor.

From contributor C:

Lamello and Kaiser had the most consistent biscuits.

Why couldn't you use dowels and a construction boring machine? The boring would go as fast as you can feed the pieces. Changeovers are fast. You can get various pre-glued dowels, so it would be even faster than biscuits.

From contributor F:

If you're consistently running into oversize plates, how about shimming one side of your cutter just enough to make them fit?

From contributor W:

I use Lamello and keep them in the freezer.

From contributor Z:

Lamello used to make a different biscuit called Fibro that was supposed to be unaffected by humidity.

From contributor X:

I'm surprised to hear of all these swollen biscuits. I use PC biscuits and very rarely have a problem.

From contributor L:

What machine are you using? We switched to insert cutters, last longer. Lamello and Kaiser brand plates have been very good; PC are poor quality. Keep them dry as mentioned above. If you are using resharpened cutters you can increase the slot width by a paper shim on one side of the blade.

From the original questioner:

We use Lamello and Dewalt joiners. The problem is that a lot of the biscuits are too thick for the slot. Not everyone who uses biscuits has the problem. People from the SW states will swear they don't know what I'm talking about.

From contributor V:

We have always had issues with biscuits swelling or being just too tight. We have had a plate joiner(s) since 1985. Our 34 man shop uses at least 200 or more biscuits per month. We only buy Lamello brand and they swell, too. We do own 2 biscuit presses now. Bought 1 back in March, 2009 and another in June. I will say that our guys now use them on all their biscuits, before they insert them. Once they run them through the press, there is no more test-fitting or guessing how tight they will be when gluing up projects that have several biscuits required. Having 6 plate joiners (Lamello, Dewalt, PC) in the shop, all having new and re-sharpened blades, I don't think one of them cuts the same. We are very happy with this "solution machine" for swollen biscuits. In our area, the humidity can easily reach in the high 80's and 90 percent. This machine does the trick for us. No microwaving here... I do see the machine is on the internet now.