Question (WOODWEB Member) :

I am wondering what you all would recommend for a downdraft table? I was wondering if there was a company that had just a bare table - I would supply the dust collection.

Forum Responses

(Dust Collection and Safety Equipment Forum)

From contributor U:

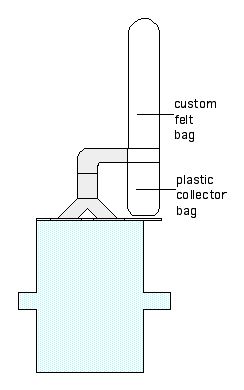

If you are supplying the dust collection, why not build your own table? I have seen a few plans around on the internet and in certain shop books. I don't do a huge amount of sanding, but after looking at the cost of tables, I built one and use my dust collector to pull the dust through. Mine is about 24" x 60", 2 x 4 frame box with plywood sandwiched top and bottom. The box stands on four legs at a comfortable working height. I drilled a series of holes into the top, and connected the 4" suction line to one end. I sealed the box with caulking. If my shop layout was different, it would pull better with the suction at the center of the table, instead of at one end. I get a strong pull on one end and weaker the farther away you get from the suction. I only drilled an area 18x32 in the middle of the table to get the strongest pull. Too many holes will cause a poor draft. Experiment and you can get pretty good results.