CAD "Stretch" Function Shortcut

Saving generic shapes, then pasting and re-sizing them, can cut down on drafting labor time. September 24, 2006

Question

I use AutoCad to make my sales and shop drawings for everything from molding profiles to furniture, and a lot of kitchen cabinets. AutoCad is a limitless program for drafting, but it can be a slow way to draw kitchen cabinetry compared to the software that is written specifically for the purpose of drawing and rendering kitchens and baths.

I wanted to share with other AutoCad drafters a method I just stumbled on that will cut my drafting time in half. After I drew my first few kitchens, I had begun to make blocks for different styles of doors, etc. and it made it easier, but still very slow. I was making blocks of all four corners of a door style and then copying them to the four different corners of all the door openings and then using extend to complete them. Somewhere along my path of learning, I took a look at the "stretch" command and decided I didn't have much use for it.

Well, the other day as I prepared to add the raised panel doors to my latest kitchen elevations, a thought occurred to me about the "stretch" command, which in spite of the fact that I have been using AutoCad for six years, I didn't even know how to use. This little command has totally changed the way I draw kitchens and probably everything else now.

I draw one small raised panel door, using mainly rectangles. I draw four short lines near the corners in my face frame layer whose end points and offsets from the edges match the overlay for the job. I then copy one of these doors to each cabinet opening and use the "stretch" command to size them to each opening. Gotta be 20 times faster than my old way. I feel like an idiot that I didn't start using it (stretch) from the beginning.

After I figured that out, I realized that I could make a whole kit of stretchable blocks that I can use to draw the face frames in plan and elevation views and the same thing for the carcasses. From now on, when I start to draw a new kitchen, I will open a drawing that contains all these stretchable blocks on their proper layers (face, carcass, door, molding, etc.) and then simply save the drawing as and type in the name of the current project.

If any of you AutoCad guys out there have discovered time saving techniques for drafting, I am all ears. If you want to ask me "what took you so long?" I can understand that, too.

Forum Responses

(CAD Forum)

From contributor S:

Glad to hear that you are now taking advantage of the stretch command. I must have looked over that command when I was in school and found out how valuable it is when I started my job a couple years ago. Learning AutoLISP programming has helped me out a lot with speed. Here is one example:

(defun c:cab ()

;define the function

;**********************************************************

;Start of Command Function

(command "-Insert" "H:/Layout/Notes/cab.dwg" pause "" "" pause

"_Explode" "Last"

) ;End Command

;End of Command Function

;**********************************************************

(princ)

;finish cleanly

) ;end of defun

This inserts a "CABINET" note block wherever you pick and explodes that block. I suggest doing that with all of your blocks. I am in the countertop business and have all of my sink cutouts and notes saved as blocks with a corresponding AutoLISP function so I can insert them. It is a lot faster than copying them all over from a template file.

I strongly recommend learning VBA (Visual Basic for Applications). I have been able to use it a couple times for creating "true-shape" drawings and estimating material, but I believe that you could use it endlessly in your application. Creating your shop drawings using a VBA Form and parametrics would be very fast, and you could link your AutoCAD VBA program to Excel and maximize your output. An example (without Excel) would be having a VBA Form that has radio buttons and/or text boxes where you select cabinet type (upper, lower, island, etc.), height, depth, width, toe-kick height and depth, drawer/door types, and whatever else those of you who know much about cabinets desire. With custom countertops, templating is regularly necessary and I don't get to utilize VBA macros very often.

From the original questioner:

That lisp routine sounds interesting. The problem I see with it in my application is I think my blocks might work better for stretching without exploding all of the rectangles. As a matter of fact, I am purposely saving a drawing that contains all of the various blocks needed to draw a set of cabinets using "save as" instead of "W Block" (write block). I am doing it that way because if I use Wblock to save them, I will be unable to manipulate the individual blocks without exploding the entire Wblock drawing and therefore exploding the rectangles that the individual blocks are mainly made up of. Also, since there are over a dozen different blocks, I can have them on their proper layers in a "save as" drawing. If I save them with Wblock, they will all be assigned to the same layer. This is all very interesting to me and if you have the time and you think you can get some better ideas through this thick skull, I will be around.

From contributor M:

If you are using AutoCAD2006, take a look at Dynamic Blocks. You will see a tremendous difference between regular and dynamic blocks. You do not have to have cumbersome block libraries anymore; you do not have to explode the block to edit it without affecting another block in the drawing. All dynamic blocks are individually editable, incrementally stretchable, rotatable, movable and many more. Take a look at it - it is going to cut your drafting time on a half.

From contributor G:

If you are drawing all your layouts with ACad, and you have been doing it for six years, then you have probably cost yourself no less than 50,000.00 so far. You need to upgrade to Cabinet Vision or kcdw (cheap), or any other drawing tool that will not only cut down your draw time but also do your estimating, cutlist, and a lot of other things, like tell you how to cut your parts out of a 4X8 sheet product. Bite the bullet, buy the software you like and go to a class that will probably cost you another 1000.00, and then you will be on the right track. I did what you did for six months. I realized to get bigger, I had to pump out more shop drawings, and revisions. So I bought Cabinet Vision. The only thing I would recommend to learn on ACad is how to draw 3D dxf files so that you can import them into your new software. At least download a free trial of kcdw or other.

From contributor P:

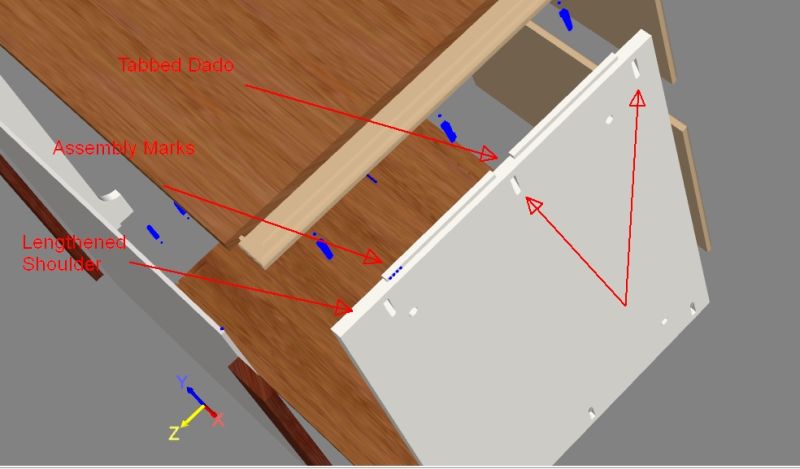

From the way contributor M is talking, ACad finally has parametric blocks. I would check that out - it is a huge time saver. Pictured here is a door I have to draw quite frequently. All I have to do is enter two variables and the door is drawn. This takes seconds. I also agree with the above post, regarding cabinets - if you do the kind of work that can utilize a cabinet program, that is a must.

From the original questioner:

I don't think there is any "one size fits all" business approach. I appreciate the advice on cabinet specific software. I actually have some of it. I have yet to implement it as it requires a better computer (faster) than I currently have. We all have differing situations and my small business is doing fine the way I run it. It has never been totally about the money for me, but more of that is always nice too. I work the business single-handedly and have no plans or desires to get large.

I doubt I would ever abandon AutoCad for a "drop and drag" type of program, although I can see myself having both at my disposal. I manufacture a type of product that varies in scope to where drawing with an unlimited program like AutoCad is sometimes the only option. Like woodworking itself, I find drafting with AutoCad to be a mentally stimulating process (read: fun).

From contributor K:

I'll take your stretch command and add to it a FROM command. Kinda makes it even cooler, eh? If you create your block on the layer you desire, group it, then insert it from your library exploding it along the way, you won't have to save as all the time. A block library is a good thing to have. You should never have to draw something twice. Lastly, Cabinetware and Cabinet Vision will never provide you with what AutoCad can (and vise versa). We use them together, but we start with cad.

From the original questioner:

Yeah, if you could wear out "snap from," mine would be in the junk heap. I use snap from constantly. I am not familiar with libraries. When I talked about save as, I said I have a drawing with a kit of kitchen cabinet drawing blocks in it. When I start a new kitchen job, I open the drawing of kitchen blocks and then save it as the current job. That way, the kitchen block drawing is always there and unchanged.

From contributor C:

Dynamic blocks rock. You really should check it out. Best new feature of AutoCAD, in my opinion. Now, if they can only make it work with 3D solids.

From contributor A:

Agree about dynamic blocks. Technically, you can't stretch (regular) blocks, but I get your meaning. Gonna pester the folks at adesk for 3d dynamic blocks... but I guess that's an inventor thing. Take a look at "refedit" too. It saves me oodles of time.

LISP/VBA is the way to go if you're ACcad based (YMMV). You can accomplish so much. The ability of the end user to customize the program (any program) for their specific needs is what makes a good program great.

From contributor J:

Everything you have mentioned can be done in ACAD using Microvellum. It is an Excel and ACAD program combined that will produce shop drawings and cutlist at the same time parametrically. It is so easy to use that you can build your own products (with some time). It will also handle estimating and material stock. It will also program CNC machines through ACAD. It is not the cheapest program available, but it paid for itself for us in about a year's time. Well worth the investment. Our drafting department has now evolved into an engineering department and that has made all the difference in the world.