Carton Marks on Finished Furniture

A furnituremaker considers how to prevent his cardboard packaging from abrading the finish on his pieces. February 15, 2015

Question (WOODWEB Member) :

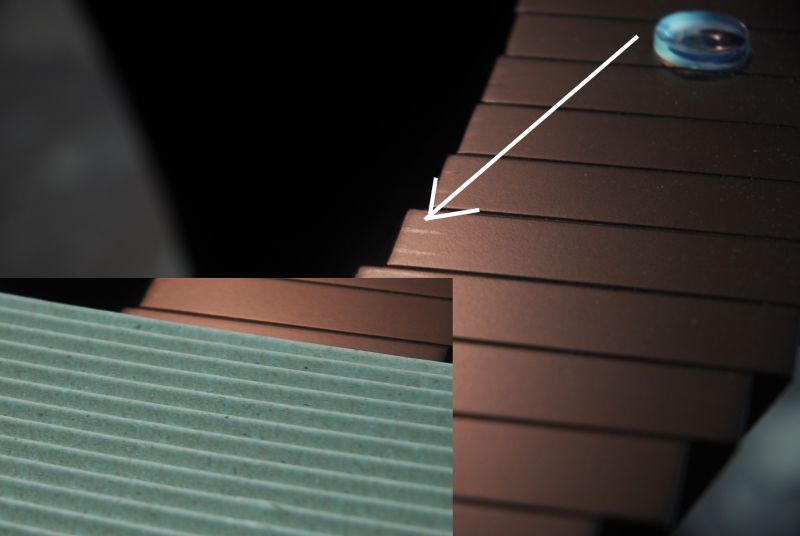

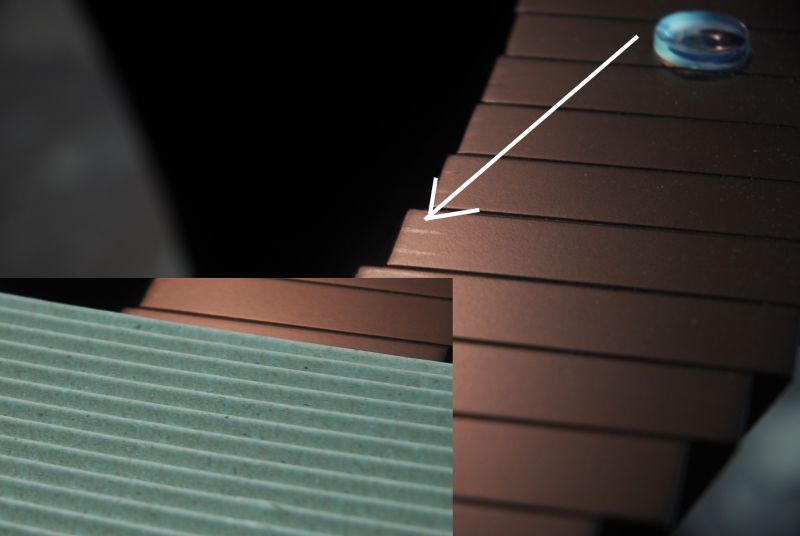

I would like to ask regarding packing marks - single corrugated cardboard marks on our furniture. We use NC topcoat for our furniture, crated upon shipping. Marks are not easy to remove we need to sand it off again and re-do top coat. How did we get these markings (last picture)? Our hypothesis is the weight of the stack made these marks, but in this case our furniture is crated. Is there any advice how we can prevent this?

Click here for higher quality, full size image

Click here for higher quality, full size image

Click here for higher quality, full size image

Forum Responses

(Finishing Forum)

From Contributor M:

The finish looks rough. It looks like pieces were shifting around in the cardboard causing friction marks and/or the NC lacquer was dry enough to package so the solvents reacted with the makeup of the cardboard. NC lacquer is not very durable.

From Contributor B:

I think your problem is that normal cardboard is very slightly abrasive, like brown paper bags. Any jostling inside the box lets the cardboard rub slightly on the finish. NC isn't as hard as some other finishes, maybe some additional protection with soft foam at corners?

From contributor A:

The NC lacquer is either not cured, inherently soft, or both. Try waxing the furniture with a carnauba based car wax such as Mother's. It might provide just enough surface slip to prevent the marks.

From Contributor J:

I wrap my assembled toy boxes with stretch wrap before packing. I used to have marks created by either the cardboard or the foam that I use for filler. Once I have wrapped the entire piece with stretch wrap, the problem has disappeared. In fact, I have had people now comment about how it is packaged since then.

From the original questioner:

Contributor J - that's what I had in mind yesterday and did an experiment on my own and tried to apply the stretch wrap. It did work actually. Thanks to everyone problem solved. I was still wondering where that marks came from. Was it a failed finish or did it come from the cardboard?

From contributor F:

Those are print marks from the cardboard. Furniture manufacturers use polyethylene foam paper to wrap the furniture prior to crating it.

From contributor K:

I think itís a combination. Your finish is not very durable (NC is at the bottom of the line in my opinion), and your packing materials are too tough. I agree with the above remarks to use foam sheet against your furniture before the cardboard. Using a more durable topcoat (conversion varnish) and giving proper cure time would have alleviated the problem too. But hey, if wrapping it in stretch wrap first does the trick then why reinvent the wheel? I would still be worried about durability though. I canít see being confident in a finish that doesn't make it past cardboard. But then again, we have a warranty to uphold with our products.

From the original questioner:

To contributor F: We were using polyethylene foam paper before but using polyethylene foam paper for packing furniture is banned in some counties that is why we used single corrugated cardboard as substitute.

Contributor K I see your point there. As far as I remember we were using polyurethane finish on our furniture, but I think they made some changes along the way to cut cost. I think the ultimate solution to this is to change the finish. If NC is not that good then I'll find some other finishes to produce quality finish.