Question

I am going to be running an overhead air line about 50" with a few drops - one man shop, 5 hp compressor. I'm convince that copper is the way to go. At the big box they have "L" or "M" copper tube (1/32 or 3/64 wall, or vice versa). Which is ok to use?

I think I read or heard somewhere that the water separating filter should be located some distance from the compressor – is this true? Also, should the main line pitch back towards the compressor and the drops go up then down?

Forum Responses

(Dust Collection and Safety Equipment Forum)

From contributor L:

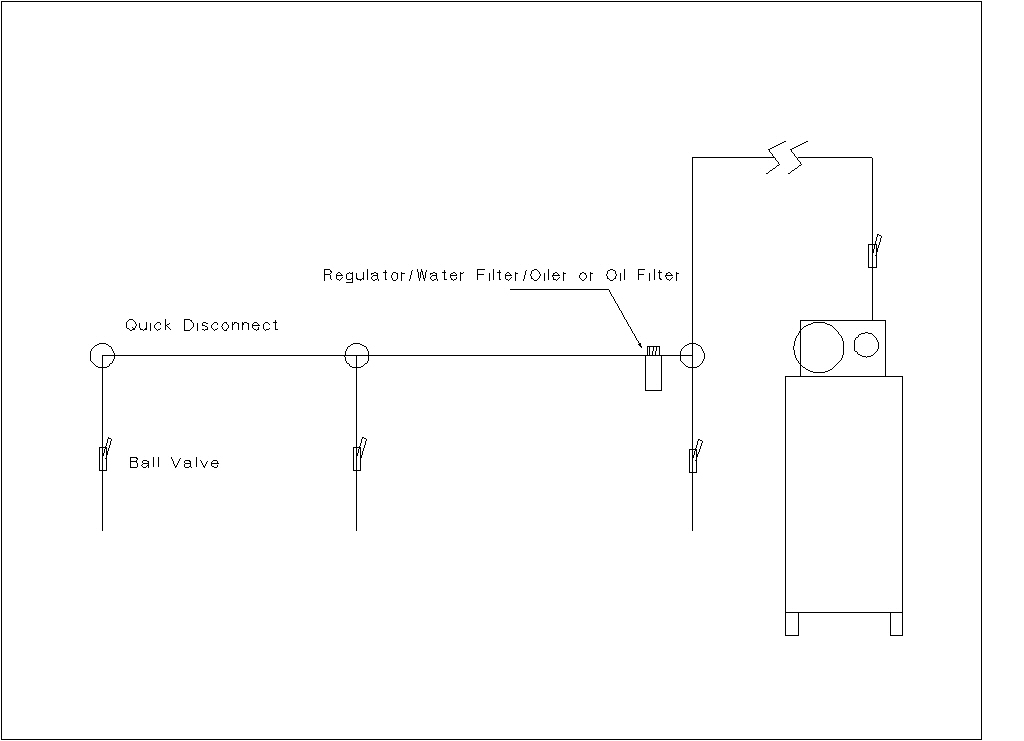

You should keep the water separator as far as you can from the compressor. It's not a bad idea to have a slight back tilt for the condensation to go back to the compressor. Have a drop and ball valve and at each quick connect to remove water from that point. Below is a small sketch.

Disclaimer: I have only permanently installed one line (50' run to pocket hole machine) with air hose. I intended to install an additional line to the bander, but just hooked up my portable compressor instead for now. I believe I will run more hose soon so I too can stop coiling and uncoiling hoses to spray, use nail guns, etc.

Your 5hp air compressor probably sits on a tank that should be more than adequate for your system. (Ideally you would install another tank on the opposite side of the system.) Copper isn't totally ideal (it has a higher internal resistance, especially at the joints) but it is the best for you application.

Whatever you do, don’t install PVC or plastic. They can explode under pressure – very dangerous! Either wall thickness of Copper is rated for your pressure ranges, but I always like to go with the thicker since it is safer and easier to sweat.

You don't really need a moisture filter as your tank will condense most of the water vapor while it is sitting there. (A particulate filter is always a good idea). Also, you can't filter water if it is in vapor form - you have to condense it first and then separate (remove) it.

This is only important if you will be spraying paint, etc with your compressed air. You can do this with a desiccant or refrigerated air dryer and moisture separator. You will want to have a way to remove the water from your tank - they make automatic drains, but you could just get away with emptying it frequently. Also, having your looped air system slope away from your compressor and installing a drop at the lowest point with another water drain is a good idea. (Your idea of sloping the system toward your compressor drains the moisture back into your tank and is not a bad idea either, but it is better have a moisture drop at the lowest point of your loop - don't let this fill up with water)!

Your system should loop around back on itself for maximum and equal flow to all drops. As far as your drops, you said they should go up then down. This is another way to prevent condensed moisture from getting to your tools. This is a wise move and I recommend that you do it.

As far as other tips, install a few more drops than you need. With copper it is much easier to add them when you install your system. Also, fix all your air leaks quickly. They make your system much less efficient and put a lot more wear on your compressor. If you can hear the leak, it is a very significant leak in terms of compressed air. You should inspect your installation under pressure with soap/water for smaller leaks. Although not as important, they add up quickly!