Question

Problem:

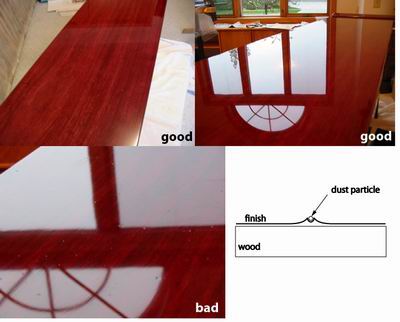

Tiny dust particles fall on the finish during the finishing process and create bumps (illustrated in the bottom right hand corner). See the photo at the bottom left. I suspect that since the finish (General Finishes Oil & Urethane Topcoat) is so thin, any small particle can break the surface tension and cause these bumps. How can I avoid the dust? For the specifics of my problem read on.

Details:

Attached to this message are three pictures of the bench and an illustration of the problem (or at least what I believe the problem to be). On this purpleheart bench, I wanted to use a high gloss finish to show off the wood. I'm having lots of trouble achieving the mirror-like shine. I started the finishing process with two coats of Danish oil to bring out the woodís character. I then added coat after coat (now roughly 11) of Gloss General Finishes Arm-R-Seal Heavy Duty Oil & Urethane Top Coat. Is this an orthodox method of finishing?

However, with the exception of the dust problem, it looks amazing (see top two photos). It dries rock hard to a mirror shine. The Arm-R-Seal is great because itís thin, and levels very well. There are no visible brush marks whatsoever. The problem (I believe) is that itís so thin (almost water thin) that even the tiniest dust particle will break the surface tension, causing a bump once dried. Iím guessing that with thicker cuts of urethane or lacquer, dust particles will just rest on the surface and not cause large bumps once dried. Iíve used small sample pieces to try buffing out the finish, however Iíve never been able to achieve anything close to the sheen that I get without buffing. In short, what Iíd like to do is stick with the finish Iím using, but somehow eliminate dust from the equation. Iíve tried suspending a plastic barrier over the bench (and slightly over the sides). I lower it so that itís about two or three inches from the surface after Iím done applying the finish. It works, but not great; thereís still a lot of dust falling on the surface. The picture you see is the best result Iíve gotten so far.

One reason I think this method (of not buffing out the final coat) may be possible is Bobís response to the Knowledge Base article on buffing out a lacquer finish (Buffing Out a Lacquer Finish). He said that his company used to buff out their finishes, but transitioned to spraying on the final sheen because it produced a more resilient finish. How does he, or others in the industry, avoid dust on the final coat? Is there some way I can create a dust-free environment or enclosure to apply my final coat? Is there a better way to approach this?

By the way, the two upper pictures labeled "good" are pictures taken at flattering angles. The photo at the bottom left is one taken at a not-so-flattering angle... I would like the bench to look like the top photos when viewed from any angle.

Forum Responses

(Finishing Forum)

Looks more like fisheye than dust... tough to tell by the pics. If it is fisheye, then you have contamination on your piece and this will continue to happen. Do the spots re-appear in the same spots after you lay out another coat? If you believe it to be fisheye, then do a search on this site for it. There have been a lot of post regarding that problem.

Avoiding dust is one thing. Eliminating it entirely is another. That requires a Rolls Royce finishing room; out of reach even for most trade finishers.

1. The way professionals do a gloss finish is to rub it out. Miniscule specs such as you are contending with are taken care of easily in the rubbing process.

2. The longer a finish takes to dry at the surface, the more dust will show. Professionals use fast drying finishes, such as lacquer and other high tech coatings.

3. It is not realistic to expect a quality gloss finish unless you intend to rub it out. If I am not rubbing out the finish, I stick with a satin or semi-gloss sheen at most. In a satin sheen, these tiny dust specs are far less conspicuous.

I'd say 11 coats of finish is more than enough film thickness already. Perhaps if you let that finish cure out really well (a month at least), you can polish it out to a marvelous result.

Polishing finishes gets into instruction that is way beyond the reach of anything here. That is not to say it is too hard for anyone to learn, just that more detail is needed.

When you get the nib file you will use it on only the effected areas. It sort of works like a shaver, scatting over the smooth area and removing the high spot.

Next wet sand and then buff. Wet sand with an air sander, working your way down to the finest grit you can get your hands on. Use a catsup bottle, fill it with warm soapy water and add mineral spirits to help lubricate the paper better. Squirt and sand as you go.

You will notice that a bumpy area feels different from a smooth area even through the sander. You will feel the drag on the sander (even a tiny bump) when the surface feels the same all over. Wipe it with a terry towel to pick up the mess. Check the surface very carefully. Where there are high spots you will notice an area around the spot that's still shiny. Go after this area again and wipe with the towel to see if the shiny spot is gone.

Go to a finer grit paper and again keep at it till everything feels the same. This is important as at this point you can no loner see the difference as the scratches are too fine.

When you're done with the finest paper, start with the buffing. I use 3M products exclusively. You will find something you like to use.