Crown Transitions for Corner Cabinets

Several ways to deal with a tricky crown molding detail at the top of corner cabinets flanked by manufactured upper cabs. October 25, 2006

Question

We were told by a "cabinet" designer that crown molding for the middle cabinet, pictured, would simply end into itself. Not geometry majors. We can't fully understand the "simplistic" ending into itself, without disabling the function of the cabinet that is pictured as opened. We realize that the use of fillers may have alleviated this dilemma, but nevertheless, is there an easier solution?

Click here for full size image

Forum Responses

(Cabinet and Millwork Installation Forum)

From contributor P:

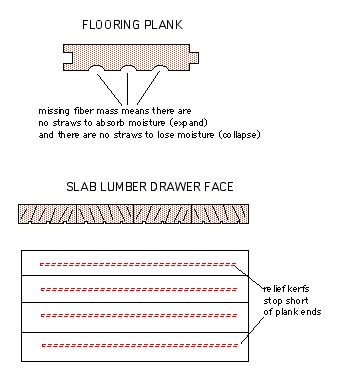

This is one way to terminate the crown into itself without interfering with the door. A small block must be added behind the crown to cover the hole that would otherwise be left where the crown tapers down to the short point.

Click here for full size image

From the original questioner:

Thanks - this is helpful!

From contributor K:

Being that it is alternating heights, you could also use alternate moldings, such as galley-rail.

From contributor T:

This is how we do it. The corner upper is made wider and deeper to keep a 16" door at all times.

Click here for full size image

From contributor N:

What do you do when all uppers must go to the ceiling?

From contributor G:

I'm not a cabinet guy, but sure have gotten involved with the crown-on-corner-cabinets issue. Isn't there a way to design these corners differently? I mean, if you do have to keep the tops flush. Can you use a wider corner cabinet that provides more room for crown termination? Or a deeper cabinet? What's the deal here!

From contributor T:

Not sure what you're asking. Can you rephrase?

From contributor G:

Why can't the cabinets be built exactly like your excellent drawing, but with flush tops? The crown would simply break around the corner cabinet as it runs around the ceiling. Just means a larger door/face frame that projects into the room a little more, right? But the corner cabinet in your drawing does that anyway. How can anyone design cabinets like the two in the photographs? Am I missing something here? Isn't it the same with a refer or oven cabinet? Don't they always have to be an inch or two forward of the base cabinets so the countertops will have a point of termination? I'm not trying to be glib. Seems like there's a simple rule here somewhere, that's all.

From contributor D:

Back to the original issue. I have installed uppers with staggered tops as shown in your photo, usually in a contemporary look; kind of mimics a big city skyline. That design just doesn't work with crown on the lower tops. I'm just a carpenter, and no authority on design, but any attempt to put crown on the cases between the tall ones just won't look right, pure and simple. You could get away with crown on the tall cases if you like, but even if it's technically possible, I'd leave it off the lower ones.

From contributor R:

I really try to build into the design what contributor T is showing. If I can't, and there are times when it's pretty hard to do, then I treat it as contributor P shows.

Without seeing the whole design, it's hard to render an opinion (emphasis on opinion). Offhand, I'd say the design could have been better.

From contributor P:

The cabinets in my picture are factory cabinets. I believe the cabinets in question are also factory cabinets. The problem with factory corner cabs is they are only 12" deep on the sides and there aren't very many options for ending crown in such a situation. Some factory cabs do have the option of deeper sides, but not many builders, or homeowners for that matter, are aware of it, or they just don't want to spend the additional money for the cabinet. It's then up to us installers to come up with a workable solution.

Of course, if you are building the cabinet, then contributor T's opinion is the best. Build it with wider sides, say 14" to 16" deep. I believe this is part of what contributor G was asking. Then the corner cabinet is wide enough for the crown on adjacent cabinets to terminate into with a square cut rather than using a return.

Contributor G, you might recognize that photo from my CD, which also shows the top of the cab with the blocking used to attach the crown. But I don't follow you on the part of your question, "...built like the drawing, but with flush tops?" Flush tops? Then, "the crown would simply break around the corner cabinet as it runs around the room."

Both pictures show cabinets that are approximately 1 ft below ceiling height. If you look closely at my pic, you can see the room crown, which is a different size and pattern than the cabinet crown. Ceiling height is 9 ft. Top of corner cab is 8 ft. However, if the wall cabs go to ceiling, factory cabs must be held down enough to run the cab crown without interfering with the doors. Custom cabinets can be built with a top rail that is wide enough to scribe to the ceiling and also accommodate the crown molding.

As far as refer and oven cabs, yes, they should be deeper than the adjoining cabs for countertops to terminate into. Custom cabs are still built 26" deep just for this situation. But factory cabs are only 24" deep, which means the countertops do extend beyond the cab face. The countertop guys must finish the portion of the counter that extends beyond the cab, whether it's granite or laminate.

From contributor D:

You were absolutely right. If you are going to put crown on top of cabinets, you have to design for it. If you vary the heights of the cabinets, you have to vary the widths as well to accommodate.

From the original questioner:

We appreciate your input. As you all have pointed out, there were other ways to solve this during the design stage. Unfortunately, it didn't happen. Our kitchen cabinetry is staggered throughout the design, so putting the moulding on the uppers only is going to be the best option. I think it will look fine. It could have been done differently and even avoided during the design stage. The designer left a lot of messed up issues for us, and coupled with the manufacturer's mis-shipment, this kitchen is going to take weeks to complete, instead of the 3 days that we planned to be inconvenienced. Such is life! Our carpenter is not pleased either. But he's doing a wonderful job accomplishing what he can during the delay.

From contributor G:

Thanks, contributor D - that's a pretty easy way to remember the rule. The homes we crown all have custom cabinets. Maybe that's why I've never run into this kind of problem. I'm kind of surprised it happens... but not that surprised.

From contributor J:

Just to beat a dead horse, couldn't the factory corner cabinet be shimmed out from the walls with vertical blocking enough to project the face beyond the adjoining wall cabinets to terminate crown? This would of course shift all the wall cabinets away from the corner by the same distance, but if this were part of the layout plan, it could work. The only sticky looking part is the exposed blocking above the side cabinets. Maybe some matching finish toe skin waste to cover it?

From contributor I:

I would do much as contributor J suggests. I would call the cabinet company and tell them their designer screwed up and you want to exchange the two cabs adjacent to the corner unit for the next size narrower. That will in all likelihood be 3 inches if the cab manufacturers still use 3" increments. Then you can do as suggested above - shim out the corner unit, and have your carpenter patch the top backs of the corner unit. That way the crown on adjacent units will die into the corner unit sides. Once the crown is up on the lower units, the patched back of the corner unit will be barely visible anyhow, if at all.

This way, it will not affect the cabinet layout (window above sink, refrigerator, etc.) and it will be much easier to access the corner unit as well.

The comments below were added after this Forum discussion was archived as a Knowledge Base article (add your comment).

Comment from contributor C:

I agree with the response above. For example, if the general size of the upper cabinets is 12 deep, the "castle corners" should be 4 inches deeper and 6 inches taller to accommodate the termination of either a 3 or 5 inch crown if the spring angle is 58/32. The designer may simply not know what he is doing, or perhaps he doesn't care what trouble the installer must endure to keep his good name.

Prefab cabinets sound easy, but there are still design issues to be delta with. A competent designer will realize these issues, and explain to the customer that either they will go with "proven technology", (keep the top of your uppers level), or they must be willing to pay extra to make cheap product look expensive which defeats the purpose of saving money.

The only answer to your problem that I have had to solve is to cut a dead 45 degree outside corner at the outside of the stile next to the corner cab. It clears the door swing, (with our overlays), and passed homeowner inspection in the three cases I am referring to.