Do I Need the Scoring Blade for a Vertical Panel Saw?

Many users get along fine without a scoring blade. February 11, 2010

Question

We recently ordered a Striebig compact vertical panel saw and are wondering if the scoring option is required. We will be using it for melamine mostly.

Forum Responses

(Cabinetmaking Forum)

From contributor M:

Scoring is necessary for chip free cuts. If you are making panel doors from melamine or HPL, it is a must. If you are only cutting melamine for boxes, it depends on your construction techniques and the quality of your finished work.

If you use face frames, the chip out will only be noticeable at the joined panels. If you are edgebanding the fronts and not using face frames, the chip out will be quite noticeable. There are different scoring systems for vertical saws. I think your saw has a carbide scoring knife option. Those work fine on melamine, but not on HPL laminated panels or veneer. Also textured melamine is a problem.

There are blades that will almost eliminate chip out, but they need constant re-sharpening and careful feed rates. You are buying an expensive machine that should be productive in your shop for a long time. Invest today so you do not have to re-buy too soon.

From contributor J:

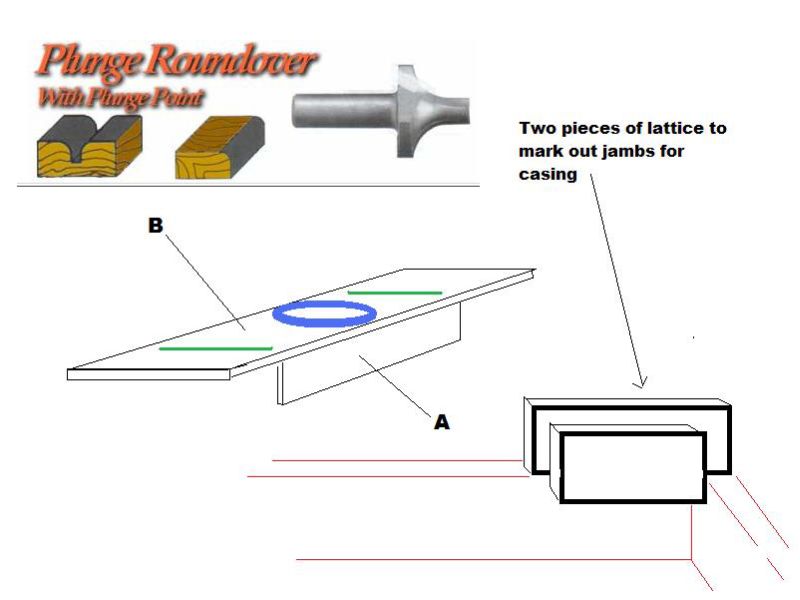

I asked the same question before I bought my Striebig and figured I could add the scoring later if needed. I have not needed it. If I need to score, I plunge score the cut. Drop the saw into the material about 1/8", feed backwards, then plunge through and feed conventionally - works great. Scoring blade would be nice but not really necessary. I find triple chip blades work best for melamine. One thing I added is digital readout and I find that this is more a necessity than a scoring blade. I think Striebig makes an add-on to set the scoring for doing the single blade scoring. Good luck with your saw - it is a very nice machine.

From contributor T:

Hollow ground blades for melamine and triple chip blades for laminate and hardwood plywood will give chip free cuts without the need for a scoring attachment. With the hollow ground you'll start to see chipping on the back side at around a half unit and on the front side at around a unit. The quality of the melamine and its core make a difference. I send the triple chip blades in for sharpening out of kindness. They seem to cut clean nearly forever.

From contributor B:

I have owned my Streibig for about 6 years. I ordered mine without scoring and have no regrets; back scoring has worked fine for me. I think the only difference is that you might have to resharpen more often without scoring.