Dust Collector Location for Widebelt Sander

This discussion about suspending filter bags above a machine brings up some good points about the value of a cyclone for catching the majority of sanding dust before it hits the filter. August 31, 2010

Question

I am trying to conserve space in my shop. I have a 42 inch wide, 2 head widebelt sander. It currently has a dedicated 5hp dust collector that barely keeps up. On other machines in the past, I have been successful with custom made fabric filter bags (from American Felt and Fabric). The airflow is so much improved with felt bags over cloth that it effectively seems to double the size of the dust collector. My new shop has really tall ceilings. I was thinking to mount the widebelt collector on top of the machine. This would produce a very short pipe run. Other than the weight of the dust bag, does anybody see any flaws to this idea?

Forum Responses

(Cabinetmaking Forum)

From contributor K:

Two flaws. No cyclone to save on emptying bags. Bags are going to be a pain to change up there.

From the original questioner:

I agree that this is a difficult area to empty bags from. As for the cyclone system: As I understand them, cyclones are for separating solid chips from fine dust. How would this help for a widebelt sander where all dust is fine dust?

From contributor A:

A cyclone would help tremendously, as it could capture 99% of the dust if done right. No bull.

From contributor J:

Even if the unit is set up on top, are you really taking that much off of the pipe run to make a difference?

From contributor G:

Why don't you hang a dust Gorilla (or equivalent) system with built in cyclone from the ceiling right at the edge of the machine and let it drop down into a 55 gallon barrel setting tight up against the sander cabinet? You still would need to climb to service the filter side, but the daily (or more often) dust collection would be easier.

Either way I would not rest the collector on the dust collector cabinet, but would hang it with rubber mounts. The sander cabinet does not need the weight or the vibration, and if you mechanically connect the collector to the sander cabinet, then all the sheet metal of the sander's cabinet will assist in radiating the noise off the collector.

From the original questioner:

I have better uses for the space adjacent to the sander. The air space above it seems free. I am fairly impressed with the compactness of the Oneida line of dust collectors. Would still like someone to tell me why a cyclone would work better for a wide belt sander. My understanding is that the purpose of a cyclone is to separate out heavy solids, but in a widebelt all of the dust is fine.

From contributor G:

The cyclone will separate out most of the fine dust, not just the heavy stuff.

From contributor Y:

If the collector you are now using does not have a cyclone and will be improved with new bags and you are okay with that, go for it. Beating the dust cake off the upper bag once in a while will help. As stated, it won't be fun dumping the lower bag, but we do what we have to maximize space. It will be easy to set it on top of the sander. You can always mess with hanging it from the ceiling later if you find out you have to.

From contributor L:

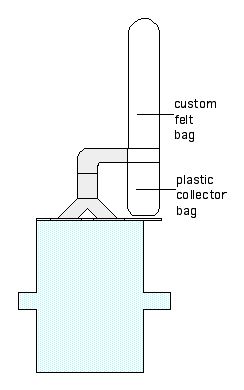

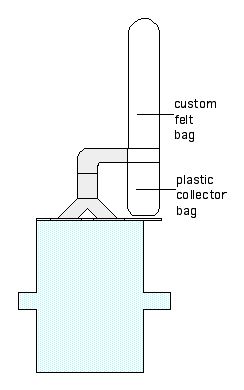

I'm sure you could set up a cyclone similar to this and have the barrel on the ground and the rest up in the air. I get up on a ladder to deal with blowing out the filter. You could eliminate the filter if you can vent outside. Depends on your local ordinance. An extremely small amount of dust goes to the filter.

Click here for higher quality, full size image

Photo courtesy of Leo R Graywacz Jr.

From contributor F:

As stated already, your understanding of what a cyclone does is incorrect and your plan is flawed.

You're trying to collect from a 2 head widebelt without separating the dust before it hits the filters. This can be done with a much bigger 4 or 5 bag collector, but it doesn't sound like you have that kind of real estate. With a typical single stage collector, you could have a bank of filters and you'll still quickly suffer from poor performance. Very simply, the fine dust from the sander is going to clog your filters and there's no amount of bag shaking that's going to solve that.

A cyclone separates dust before it hits your filters - not just the heavy dust, but the majority of any dust going though.

I suggest you do a little research. How many cfm's does your machine require? Just buying a bigger collector without knowing how much air flow you need could very well be a waste of money. Lastly, it sounds like you may be running several collectors? If so you may be better off consolidating into 1 large collector, which could give you more floor space and better collection throughout the shop.

From contributor U:

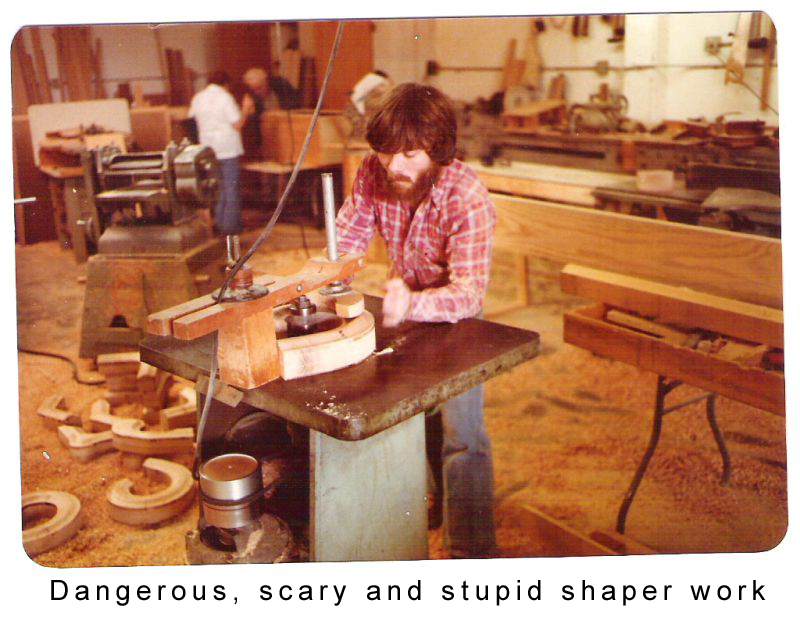

I put a 7.5 HP collector on top of a storage room about 15 ft from the sander. Maybe I will add a cyclone at some point, but at least the fines are in the bag and we run a forklift in with a pallet to roll them onto after changing. A local retired farmer takes them for composting. We only have to change every 5-6 weeks, so it isn't too bad for our small volume.

Click here for higher quality, full size image

From contributor Z:

Cyclones filter 99% of all dust and chips. They do not separate the fine from the coarse. Their sole purpose is to prevent the dust from ever meeting the filtration medium.

The problem with sanding dust is it clogs the filtration like crazy due to its size. The distance increased will not make a huge improvement, since you are only trying to suck dust instead of chips. Move the collector to a higher location that is easily accessible.

From contributor V:

I have an Oneida cyclone set up for my wide belt similar to contributor L, but I opted for the larger cartridge filter. I too was skeptical about how well a cyclone would separate fine sanding dust, but now I'm convinced it's the way to go. It sucks much better than the 4 bag collector with the same hp that I'd been using, and is way easier to empty. The collection pan under the cartridge filter rarely has more than 1/8" of dust in it after completely filling the collection drum, so now we only check it every few months.

From contributor R:

We have a central collector with a cyclone, and as everyone has said, almost all the dust is separated by the cyclone. Our bags shake down automatically 5 minutes after each shutdown. It takes a couple of months to fill the drawers under the bags! Cheap dust collectors often rate their air flow with no or little resistance. Good cyclones will have a fairly long cone, not the stubby ones I see on some units.

From contributor U:

When we had the sander hooked up to the main system, the cyclone did work well. When we added a moulder, we needed to free up the capacity. It works well for us this way because one farmer uses the shavings from the cyclone (minimal fine dust) and another wants just the very fine sanding dust, which is already in bags and ready to go.

From contributor P:

If you are just moving into a new building, you might want to check on fire safety codes. Here, any machine that produces dust, as opposed to chips, must have the dust collection system outside the building.