Easing the Edge of Shaker Style Doors

A light touch is all that's called for. April 6, 2007

Question

I have made a few shaker style doors. They look great with a reversed raised panel and have the feel that I like. Since this is the first time I've done this style of door, I'm wondering what the best way to handle the edges will be. What, if anything, do you do with the edges for the best look?

Forum Responses

(Cabinetmaking Forum)

From contributor M:

For shaker jobs we just barely sand the sharp edges off by hand. This is what I have seen on authentic shaker pieces and what every customer has wanted. The shaker style is meant to look like they built it way back then when they didn't have router bits.

From contributor T:

I use a 1/16" round over. Looks good.

From the original questioner:

Thanks. I was thinking of just breaking the edge with a sanding block. I ran some shaker style for a friend several months ago on my RBI door machine and I think he rounded his slightly, but didn't get to see the finished door.

I haven't seen a 1/16" router bit. 1/8" is my smallest. Can you even tell it's been hit with 1/16"? Since these doors are birch, I think I might feel safer with just the sanding block.

From contributor S:

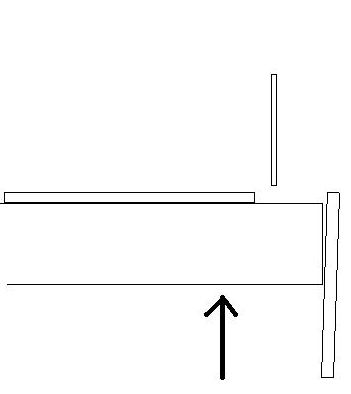

The 1/16 bit really is tiny, but if your doors are flat (dead flat), it works good. I set mine so the lip just starts to cut (64th?) and then run a pad sander over to kill it. Finish sand before routing, clean base plate on router. I made a block that PSA paper sticks to with the rad built in, one swipe down and done.

From contributor P:

We use a Slick Plane for breaking edges a lot of the time. Faster than messing with a router, and no dust. It's also cheap.

From contributor M:

Also, some of the ones we do have been distressed to give the old worn look. If you take the random orbit sander and hold it at a 45, then you take the corner off and you can't hardly help to take more off the corners, which adds to the distressed look.