Edge-Planing Boards for Width

Cabinetmakers discuss the fine points of sending boards through the planer on the narrow dimension. December 28, 2005

Question

Has anyone successfully used a planer to edge and size solid wood to dimension through a planer? I was going to try a test by setting up a jig with two L- shaped boards holding the stock vertical as it moved under the cutter head. I wondered if the experiment would be a waste of time. It seems the biggest issue would be the stock maintaining 90 degrees to the face.

Forum Responses

(Cabinetmaking Forum)

From contributor A:

It works okay if the stock is narrow, but wider parts have a tendency to twist, creating an out of square edge. Your L-shaped blocks might help some. I would recommend a shaper with a power feeder and an out board fence. Edging the stock between the fence and cutter will make the final width exact so the blank size is not as important. Also you can climb cut troublesome grain materials.

From contributor B:

How about stacking a half dozen or so and sending them through? I do it all the time when I need parts to be the exact same width in a project.

From contributor C:

I do this as my standard preparation of solid stock edges. If I know the grain direction of the boards and run them accordingly, my planer puts an excellent finish on the edges and will plane the widths to a tolerance of plus\minus .005".

It works best if you gang several boards of equal widths together and squeeze them tightly together as you start to feed them to the knives. I am very meticulous in my work and although the squareness of the edges is not 100 percent perfect, it is close. If I am careful about starting the boards into the planer correctly and keeping them tight to one another, I find the amount of error to be within my tolerance.

From the original questioner:

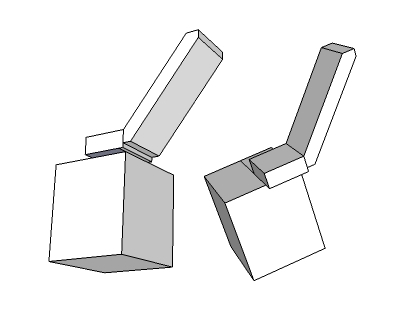

I got the planer jig done for the edging process. So far the results are perfect. The stock is consistent in width and the edge is 90 degrees. The vertical plywood pieces are notched to allow the machine to move downward but the higher infeed and outfeed heights of the vertical plywood do a good job supporting stock up to 4 inches.

Click here for full size image

Click here for full size image

From contributor C:

Sometimes a good cabinetmaker complicates a simple process. The next time you want to edgesize a few pieces of stock, rip them 1/16" wider than you would if using your jig. Then, run them through the planer on edge, ganged tightly together, and check them with your square. If you are dissatisfied, rerun them with your jig.

Over the years I have learned to try the fastest and simplest approach that will yield the results I want instead of assuming the simpler method will fail and putting a bunch of time into complicated jigs that sometimes make the whole process take longer. Your jig will only do one piece at a time and you designed it so that depends on one small spot on the knives that will become dull. Then you have no where else to go.

From contributor D:

I have sent stock on edge, singly or ganged, probably every working day for the last 30 years. It works. No jigs are needed, but your planer needs to be set up properly. I'll glue for width right out of the planer. I have used Powermatics, large and small Delta, Casadei, SCMI, and Sicar planers to do this, but have no experience with a benchtop.

Once, with a new planer, I had to file and reseat the pressure bar and the outfeed roller on one side since they would not slip as the board exited. This created a lot more tension on one side of the board than the other, and would slowly tip the board out of square. Once fixed, it worked perfectly.

I agree with contributor C that the fastest, most direct way of doing things is best. Realize there is a limit - that is, you can't send a piece of 1/4" thick stock x 8" wide thru on edge and expect it stay square. But for the run of the mill items, it works.

From contributor E:

The only jig you need for this operation is a good square to insure that your jointer fence is set at 90 degrees when you joint the edge that your lumber will be sitting on when it travels thru the planer. Edge planing is an everyday operation in my shop, and the jointer is the machine where you square an edge. The planer is for thickness planing.

From contributor C:

I agree except I changed to doing it the opposite way. I use the jointer to get the edge straight and reasonably square. Then I rip .040" oversize and since I know my saw blade is always square to the saw table, and that sometimes due to bows in the stock etc. the jointed edge won’t always be perfectly square, I put the sawn edge down on the planer bed for the first pass where I remove approx .020". Then I flip the boards end for end and run them again to remove the final .020". This way, I don’t worry about square, plus my planer leaves a better finish than my jointer.

From contributor F:

Everyone here is saying basically the same thing, although I think you can totally skip the jointer operation that the original questioner suggests. Order your stock straight line ripped or S3S. If you don't have a straight line, rip your stock to 1/16" full and run your pieces on edge either thru your planer or widebelt sander. I prefer the widebelt. Sand to 120 and they're done- no more touching the edges. The jig is a great idea, but not necessary, in my opinion.

From contributor C:

Contributor F is correct in theory that if you purchase your stock straight lined you can then just rip four 2" pieces from a nine inch wide board and they will be perfectly straight to run through the planer. For some reason, all the boards I have bought in the last few decades produce boards that are less than straight when the overall width of the straight lined board is divided into two or more pieces.

From contributor G:

I have done this for at least 15 years. A long time ago my boss and I decided to dimension our stock this way. I have had several different bench top planers over the years and it has worked on all of them. On rare occasions, on wider pieces the stock has twisted and messed up my edge but I was able to correct it. This has happened 3 to 4 times at the most in 15 to 20 years and literally miles of stock. Plane away - you don't need any jigs and the edges are crisp and clean and sometimes a little too sharp.

From contributor H:

I have been using my Dewalt bench top to bring stock to perfect width and it works great. I did run into a problem with squareness once and have since run one pass on the jointer and then on the planer to size.

From contributor I:

I use a Dewalt benchtop planer to size my face frame stock too. It used to take a lot of labor to constantly switch between 1-3/4” and 2-1/4” inch measurements with every run of face frames and to get them dead on. Then I bought a Digi-Planer digital scale from a company called Digi-Kit for $99 and after I installed and calibrated it, I can switch to any thickness quickly and it is dead accurate. I just went to the website and I didn't see it listed, but it would pay to call and see if they still have them if you are sizing face frames this way. I would buy it again at twice the price if I had to.

From contributor J:

To the original questioner: I've done the edge planing with a jig like you made. My feed roller wore out as the blades got a little duller each time. My lumber supplier sells stile material in most wood types in 2", 3" and 4" s4s to 13/16 thick. That solved all my planer work.

Click here for full size image

Click here for full size image