Edge Lipping Planer Choices

Here's a closer look at the high-quality tools available for flush trimming shelf edges and similar components. March 22, 2013

Question

Anyone have reviews of the Hoffman edge lipping planer? Any shop made jigs for a router that do the same thing? I am looking to purchase a used edge lipping planer.

Forum Responses

(Cabinetmaking Forum)

From contributor G:

I've got a Hoffman (orange, right?) and it works pretty well. Quick to get things semi-flush, but variations in materials necessitate setting it just a tick high and sanding it flush. We pretty much only use it for flushing hardwood edging on plywood shelves, etc.

From contributor M:

I'm a one man shop and bought one a few years ago when I needed to flush trim a 2" solid wood edge on a veneered table. I swallowed hard at the price new, but had to have it for the project.

It took a little bit of practice, but it worked great for the project, and now it's really convenient for flushing face frames or shelf edges. As stated, you may need to leave it a little proud and sand flush if the plywood is not dead flat. I have no regrets having spent the money. I bought mine directly from Hoffman. They were great to work with and I seem to recall it shipped out same day or next day.

From contributor B:

Mine's good - highly recommended. I left the cut a little high for years, then checked the setup one day and found that the knives weren't running perfectly parallel to the shoe. I'd never considered that the factory setup might be off, but a little adjustment did the trick and I can cut much closer now without worry.

There's a learning curve, and for me, the outboard handle tended to be a problem, as my tendency was to put too much down pressure, skewing the cut. It lives in a drawer, and the machine's much better without it.

From contributor K:

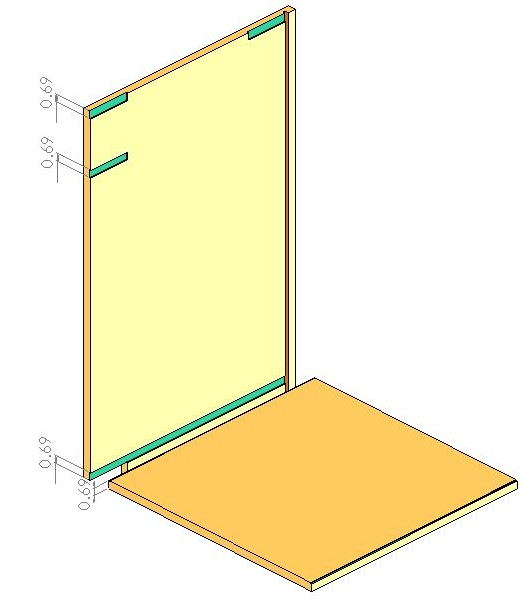

For wide banding on large panels, the Hoffman is hard to beat, though pricey. Virutex makes a less expensive unit that might be worth looking into. For banding up to an inch or so on large panels, a router set up with a wide sub base extending halfway across the base housing and flush with the end of a straight bit works well. For smaller panels, powerfeeding through the shaper with a similar setup is quite accurate, faster, and allows for dust collection. Climb cutting prevents breakout at the face of the banding.

From contributor B:

Being a cheap sort of guy, I bought the Virutex first. You get what you pay for.

From the original questioner:

Thanks for the responses. I ended up picking up a Festool MFK 700 router that has the horizontal base for edge trimming. Seems to work great, super dust collection too. Plus I get the added trim router benefits. Picked it up locally on craigslist for $300... Used twice!

From contributor U:

A quick tip for all who have a Hoffmann BH-556 lipping planer already - only use the side handle to set the machine on the board and to lift it up when finished. During the actual planing process, place your left hand on the front knob, not on the side handle, to keep from digging into the board.

From contributor J:

Sounds like you already bought your tool but figured I'd throw in a nod towards the Virutex anyway. I bought mine several years ago and can say without a doubt it was money well spent. I can dial it in so it cuts flush, just barely scraping the surface. I've cut many hundreds of shelves with solid edges and can't imagine not having it. Not sure how your router will work for thicker edges, but if you do look into lipping planers again, the Virutex is a very good tool for quite a bit less money than the Hoffman.

From contributor D:

The Lamello Cantex blows away the Hoffman and the Virutex. I bought mine back when it cost around $1000, and am glad I did. Now it's something like $1800 with the edge guide, but you'd have to check. Amazing tool though. The conical three knife cutterhead is the key. If anybody else is in the market for a lipping planer and can justify the price, it would be a shame not to try one out before buying one of the others. You'll be sold.

From the original questioner:

Well, after using the Festool MFK 700 router I gotta say it is fantastic for flushing solid wood edging. I picked up a few downshear bits and it cuts like a dream. The dust collection is super as well. The nice part is that I have a really nice trim router too! I own many Festool products and they are all great but this one is worth its weight in gold if you do much solid wood edging. I can't see why it wouldn't shine in a higher production environment too but if I was using it all day I may consider a heavier dedicated machine. Perfect for a small shop though.