Question

How would you approach making square turnings, like Morris columns? These are getting very popular. I think most people use a fourth axis attachment for their CNC's. I have also heard of people using old lathes that have fixed shaped knives that spin instead of the stock, with cams that control the distance to the stock. Does anyone know anything about these kinds of lathes or another way to approach this problem?

Forum Responses

(Solid Wood Machining Forum)

From contributor O:

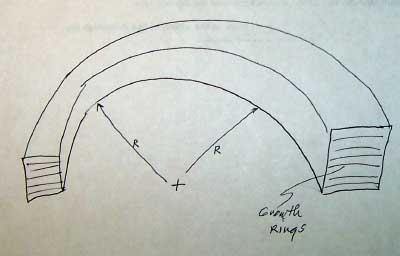

Those type of turnings are indeed produced by the Mattison 66 or 69 type lathes. They have a rotating cutterhead that the wood blank backs into, and cams determine the cut face on the blank. They can easily do conventional round work, but can also do the faceted turnings. Beyond round, the most common are square, hexagonal or octagonal in section. These lathes - and particularly their cutterheads - are amazing things. The setup and operation is difficult. There is usually some crusty, bent, 8-1/2 fingered old man nearby that is the only one that knows how to set it up.

Small quantities could be done on a CNC, but nowhere near the speed of these old Mattisons. I spent years in a stair shop that had turnings made in a nearby turning mill that had 6-7 of these lathes, and they could turn out a 4" newel in about 30 seconds. Here is one.