Five Points for Efficient Sawmilling

Gene Wengert shares his expertise on sawing economically and profitably. January 29, 2004

(Sawing and Drying Forum)

From Gene Wengert, forum technical advisor:

1. Compared to sawing a log entirely into lumber, cant production (7 x 9 x 100") produces 6 BF more per log (estimated 3% to 6% more yield; +80 BF per MBF log scale); reduces production time by 33% or more; reduces production costs $10 per MBF; value of products produced is increased by about $4 per log ($50 per MBF log scale); less sawdust.

2. Cutting parallel to the bark on upper quality faces will increase lumber value by 7% or more per log (for good quality logs).

3. Reducing log overlength is great, as every 3" extra length on a 12' log requires 2% more sawing time, has 2% more wear on the saw teeth, weighs 2% more so tears up equipment faster, and means that the next log up the tree is a little smaller in diameter.

4. Reducing lumber thickness variation and then reducing average thickness can increase yield. Many mills cut 1-1/16" average with little variation; other mills cut 1-1/8" but have lots of variation. The extra average thickness is needed to prevent any thin lumber; the extra thickness is waste. The difference between 1-1/16 and 1-1/8 is nearly 5% more yield at the end of the day. (If you must cut thicker for the customer, charge 5% more??)

5. Cutting for grade can be profitable. Actual mill results: average sawyer got 18% Selects and Better from No.2 long, while a better sawyer got 30% which is 21% more value per log. Opening face width: 6% increase in yield when properly chosen over conventional. One conclusion is that a scanner costing $60K per year is worth it for most mills at 1 million BF per year or more.

No. 5 is the one that I will respond to, and add that sawing for grade starts at the log landing. If possible, buck your tree so that the defects are near the ends of the logs. If you are sawing them yourself you'll get higher grade lumber; if you are selling logs you will get bigger paychecks. Throw the knotty sections in the stove.

I don't understand #2. What does cutting parallel to the bark mean?

From Gene Wengert, forum technical advisor:

The sawn face, especially for opening faces and until lower quality is reached, should run parallel to the bark, rather than parallel to the pith.

From Gene Wengert, forum technical advisor:

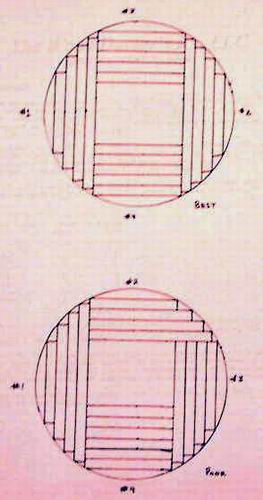

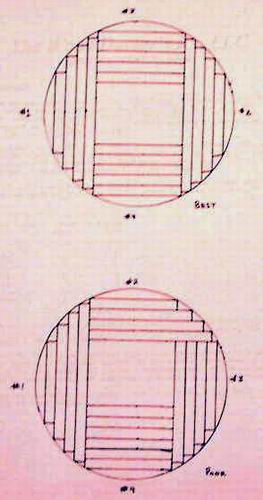

Check the image below. The top picture, using 180 degree rotation from face #1 to face #2 so that the rings on the end of the lumber are balanced from edge to edge, will produce less crook (side bend). The reason is that any juvenile core shrinkage will be the same on each edge. Other advantages, including less edging, have been discussed before. The bottom picture is how to develop more crook or side bend, if that is what you want.

Okay! If I change 4/4 boards from 1 1/8 inch thick boards to 1 1/16 inch thick boards, how many cuts would I have to make in a log to save a board? How many of the 12 to 30 inch logs that I saw in a normal day are going to produce the 5% extra lumber? In a 24 inch log I make 6 to 7 cuts on the faces of the 8 inch side of the tie and 7 to 8 on the 6 inch side. I would need 19 cuts on a face to gain a board. (I need a savings of 19/16 to get my 1 1/16 board and 1/8 kerf.) We already know that I make money and save time by selling the low grade cant as a tie and so I can not get the cuts needed from there. So it looks like I could only save a board from the 26 inch and larger logs, which is not going to cover the 20 or so 12 inch logs I sawed. What worked on paper did not work where the blade hit the wood. I have to wonder about people who think that sawing 1/32 finer than me is going to make more lumber at the end of the day. Now there is a large difference in the 3/8 taken by the circle mill to the 1/8 of my band. But in an 8 inch log making 4x6 pallet cants, there is no savings and they can do it a lot faster.

From Gene Wengert, forum technical advisor:

Not every log will produce an extra piece of lumber. Some will produce a wide piece and some an extra piece and some a piece that is another foot longer. Other logs will be the same. If you make a drawing for every 1/10 inch diameter, you will see what I mean. It is well documented concerning the increase in yield. What if I used a blade 1/4" thick or 1/2" thick? Do you mean that there is no difference in yield?

From Gene Wengert, forum technical advisor:

Consider the sawing examples that I posted above. In the lumber that is horizontal in the picture, there are 10 kerf lines that are important... the two in the slab do not matter, as they are in the waste anyway. The total thickness of the kerf is 10/16" less with a saw that is 1/16" thinner. So, with a thin saw I can get the same yield as a thicker saw if my log is 10/16" smaller in diameter. With a log that is the same, once in a while, I will get an extra piece. (Note that with a log that has the same diameter, with a thin saw, I will get the yield of a log that is actually 10/16" larger in diameter.) If there is taper in the log, with thinner kerf I can often get a longer outside piece on the second face.