Floor Structure and Moulder Chatter

An understrength floor system beneath a piece of heavy woodworking equipment is a recipe for trouble. February 4, 2011

Question

Is there a recommended floor thickness under a moulder? A year and a half ago the company I work for installed a Weinig Powermat 1000. Almost since day one we have had a problem with chatter. We have had techs here to look at the machine and no one can find anything wrong. Several people have told me that the floor is not thick enough. The problem is the owner does not believe this is possible. They have spent thousands of dollars trying to pin the problem on vibration. Even the vibration expert recommended a 2 inch thick steel plate under the machine. Any suggestions?

Forum Responses

(Solid Wood Machining Forum)

From contributor S:

Mine just sits on the leveling pads. The concrete floor is 3 1/2" thick. I'm having a hard time thinking it's the concrete causing the problem. If you have chatter, something inside the machine isn't adjusted right. They make anti vibration (shock) pads - maybe look at that.

Not trying to point fingers, but have the only techs to look at the moulder been Weinig employees? If so, find an independent tech to check everything out on the moulder. They might have a serious problem they don't want to admit.

From contributor A:

What is the current floor?

From contributor R:

I have seen this problem twice before, once on a moulder install, and once on a grinder install. Old wooden floors was the culprit on one; the other had a train track about half a mile away and the vibration from the train transmitted into the grinder and ruined the lineal bearings in a very short period of time. I would agree - have an independent tech look at the problem. Maybe they can see something others have not seen. Dr. Dave Rankin might be able to help you.

From the original questioner:

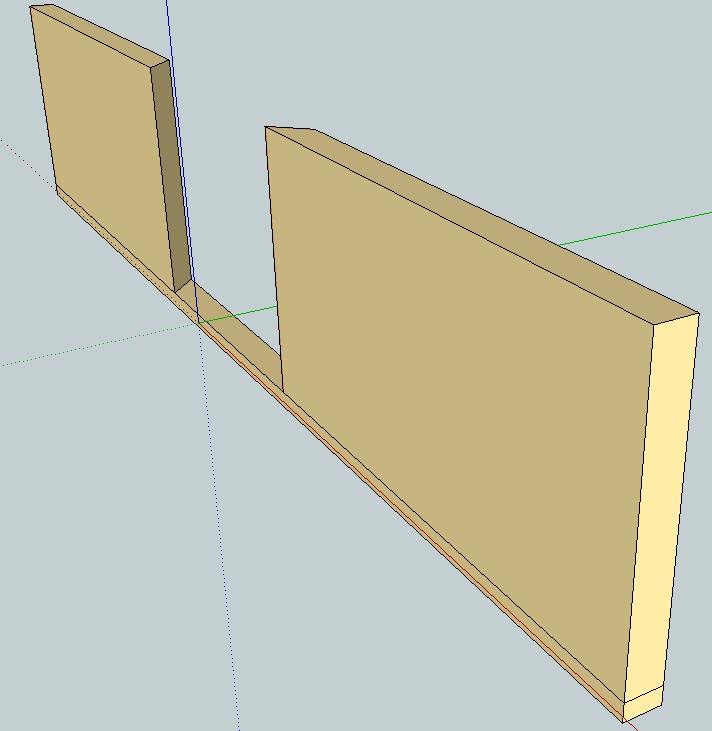

The floor is 6 inches thick, but there is a crawl space underneath with no support under the moulder. The way the supports are spaced out, none of them land under the machine. This is the third machine we have had in this spot, and we have had trouble with all of them. We just assumed that the other machines were the problem.

From contributor R:

With the information you just provided I would say the Weinig techs were right in what they told you. It's very sad to hear you have spent all the money on machinery, but not the floor on which it sits.

Why don't you put some bottle jacks under the floor to support it? See if the problem goes away. If so, I would pour some cement and place the bottle jacks there permanently.

From contributor A:

You have more than enough data to support the floor problem. The vibration expert must get a kickback from the steel industry when he spec'ed 2" steel plate. At the end of the day, the floor needs to be structurally sound. Adding more weight to the floor may make the problem worse. The molder must weigh a lot on its own. Beams/lolly columns are your solution, not steel plate.

From contributor S:

Can you move the moulder to a solid part of the floor? If that's not an option, do what contributor R suggested.

From contributor D:

This has been an issue for us as well. An Ogden orbital frame saw was actually moving across the floor when it ran. The owners just acquired a massive Intermac CNC for granite/glass cutting, and they're building a whole new wing with a thick concrete floor just for it.

From contributor O:

Regardless of whether the chatter is due to the floor or not, you need to correct the foundation. It is inadequate for that machine. Simply putting a steel plate underneath and on the same flimsy floor probably added to the problem. You must have a solid foundation under this machine. A rigid steel structure on solid piers would work, or a solid concrete pad. Investing $200,000 plus in a piece of equipment and not providing for a proper setup is beyond penny wise and pound foolish. Fix the foundation, and then address the issue with chatter if it still exists. It will cost you a fortune, if it hasn't already, if you continue to try to work around it. Also make sure you get a molder tech to relevel after it is placed back on the pad. This is critical. I have installed hundreds of machines, and can remember few if any instances of a machine properly leveled by a customer, maintenance, etc. Weinig is a standup company and I'm sure they will address the issue once the machine is properly placed.