Question

I do all sorts of mica laminations but never laminated actual wood to a curved piece of wood. I would normally use contact cement, but my stash is old. I have new Titebond 3. Can I use this or will it finish lumpy? Not sure if yellow glue can be used for lams. The veneer is maple and is 1/16" thick.

Forum Responses

(Veneer Forum)

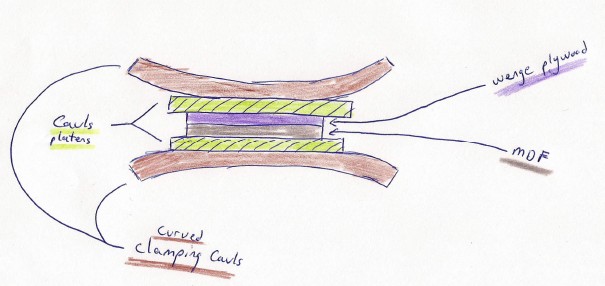

I'd just buy a new can of contact cement. If you're too cheap to do that, the Titebond will work. If it's a large curved surface, I'd glue it up and use a vacuum bag to clamp it. If it's a small piece, I'd glue both surfaces, let them dry, and then put the pieces together and use an iron to create a hot melt bond between the veneer and substrate. I use all three methods - it just depends on how big the lamination is, and how easy it is to align the parts.

PPR is not subject to spring back or creep in the ways that PVAs and contacts are. Maple, being highly tensioned, will want to move back to its original shape and form (straight and true). You want it to be curved and that is not its natural position, so you need an adhesive to make it stay there.

PPR is the glue used in the manufacturing of plywood. It is rigid, cures like concrete (it's permanent and can not be reactivated like PVA or contacts).

This concrete permanent bond type highly minimizes movement as the veneer stabilizes or tries to stabilize. If it can move, it will move, and this is known as checking.