Question

I have heard of using contact in the field of a HPL/substrate and PVA on edges.

1. Do I coat HPL and table top with contact, let dry, and then PVA and clamp edges?

2. Is this a waste of time or is it much better than just contact?

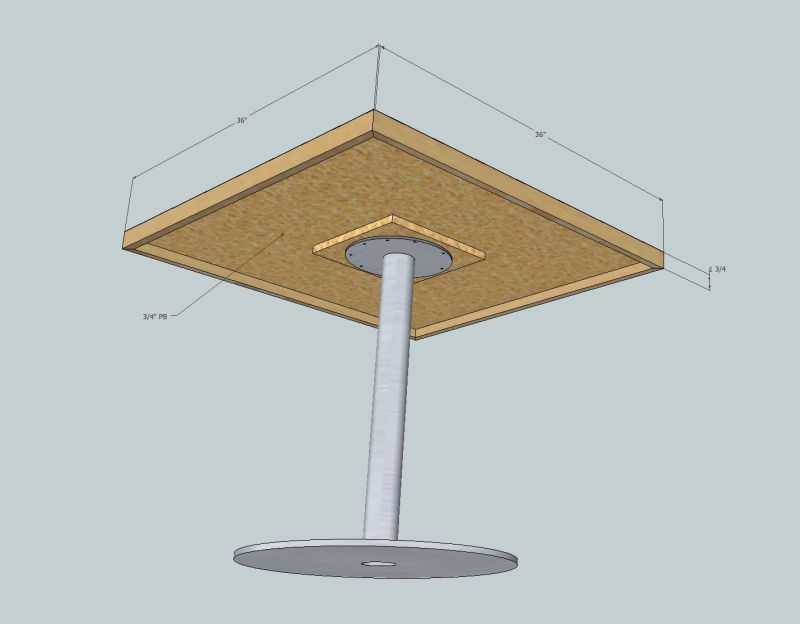

3. I plan on copying some existing tops in the restaurant. They are merely 3/4" PB with 1 3/4x 3/4 solid maple edges. A backer wasn't used and the tops are flat. Why?

Forum Responses

(Laminate and Solid Surface Forum)

From contributor R:

1 and 2. If you are talking laminate edging, most will do the edges and then the deck. If using a contact adhesive, you do need to coat both the laminate and substrate. Using PVA on the edges is possible and will give you some added strength and moisture resistance.

3. The lack of warp is likely due to good acclimation of materials and the relative small size of the table. You may want to verify if the back is covered with a sealant.