Finishing for Wet, Humid Environments

Reprinted with permission from The Hardwood Council website.

Bathroom hardwoods go beyond the vanity

Oak. Ash. Cherry. Maple. Hickory. Walnut. For centuries, these and other hardwoods have been preferred for fine furniture, cabinets, flooring and millwork. But are they appropriate for the bathroom? Absolutely. Builders, architects and designers are taking advantage of durable new finishes to bring hardwood beauty to bathroom applications they never would have considered before.

Technologies offer watertight solutions

No place in the home is more humid or damp than the bathroom, and building professionals have been reluctant to place hardwood flooring and millwork in that kind of environment. Yet, recent gains in wood treatment and homebuilding technology make it easy to install and maintain hardwoods in the bathroom, all but eliminating any problems with cracking, peeling, warping, buckling and water marks.

These advances include:

Catalyzed Sealers. Manufacturers are pre-finishing cabinetry and millwork with durable, baked-on finishes that chemically bond with the wood to prevent moisture penetration.

Quick-Curing On-Site Finishes. This new generation of wood finishes can withstand moisture, while maintaining the flexibility to accommodate wood's natural expansion and contraction.

Improved Environmental Controls in the Home. Controls and ventilation systems have dramatically reduced fluctuations in relative humidity in the bathroom.

Know How You'll Finish Before You Get Started

The right finish for any application depends on your budget, as well as the traffic and spillage you expect the wood to encounter. Less impervious finishes can be applied to decorative millwork, but tub surrounds, floors and countertops merit high quality finishes and close attention to detail during application.

Today's finishes offer water resistance that old-fashioned shellacs and varnishes never could. Blends of synthetic resins, plasticizers and other film-forming ingredients bond to form a watertight seal, yet do not peel when the wood expands and contracts. These finishes are called "convertible" and you'll want to choose one that is specified for the bath.

Convertible finishes cure to a very hard film that is relatively impermeable to moisture, making them a good choice in areas where water splashing and spills occur. They include:

Moisture-cure urethanes, such as polyurethane, are the hardest finishes. They are non-yellowing, but your decorating options are limited to a glossy finish.

Acid-curing Swedish finishes are fast-drying and non-yellowing, and even more elastic than urethanes. Swedish finishes produce an excellent end product, but they are probably the most difficult to apply, requiring a finely sanded application surface.

Lacquers are hard and water-resistant, although their brittleness may make them vulnerable to cracking and peeling. If you choose a lacquer for decorating reasons, be sure to use a high-quality product that will cure to a flexible film.

Installing a Hardwood Tub Surround

More than any single bathroom application, the hardwood tub surround is the one project most likely to put your finishing skills to the test. The various challenges of installing and finishing cabinetry, paneling, millwork and flooring all can be addressed in a tub surround. And, during its lifetime, the wood you install here will have daily exposure to drastic changes in temperature and humidity. It will encounter soap, shampoo and cleaning chemicals; as well as countless spills and splashes.

However, as the growing popularity of the hardwood surround indicates, building one right is easier than ever. Here's how:

1. Select Your Materials--When using hardwoods for the tub surround and decking, the first decision you'll encounter is whether to work with pre-finished materials or finish the wood on-site. Your alternatives for the decking material include either tongue-and-groove planks or flooring strips. Hardwood bath surround panels are custom-milled in most situations. Other solutions include off-the-shelf hardwood paneling, pre-milled doors or the plank flooring used in the deck.

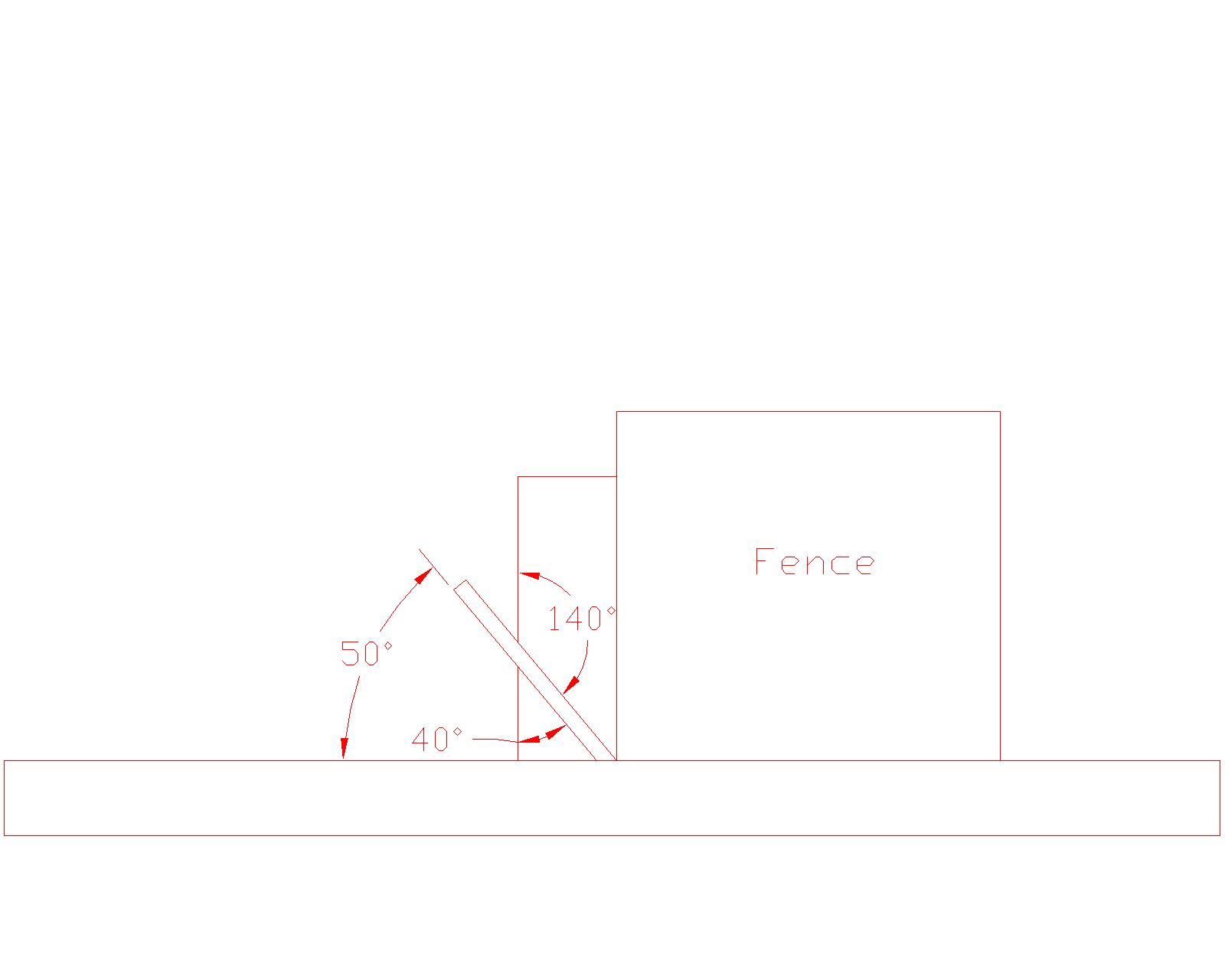

2. Build the Frame--After the plumbing has been roughed in, measure the tub area and build a box frame using pressure-treated, 2" x 4" lumber and rabbet joints (see diagram). Be sure to leave an access point for any future repairs. Surface the frame by nailing 1/2" or 3/4" waterproofed plywood to the top of the box frame, then cut the hole for your tub. Finish all framing with a weatherizer and be sure to use galvanized nails.

3. Mount the Surround--Mount the hardwood surround material selected in Step 1 to the box frame, again using galvanized nails. Side panels should be applied in the same manner, using a corner moulding to hide both the joint as well as expansion and contraction gaps. If you choose to site-finish, seal all sides of the surround before mounting it to the box frame. Apply sealer generously to the back side of the paneling especially, as this will be the last time you have access to it.

4. Install the Deck--For a hardwood deck lay a vapor barrier of 4 to 6 mil polyethylene film over the plywood surface, then fasten pre-finished or site finished hardwood plank flooring or tongue-and-groove flooring strips with flooring nails at 8-inch, off-centered intervals. Once again, be sure to thoroughly seal the backside of each strip before installation if using unfinished flooring.

5. Finish the Wood--If you are site-finishing, fill any nail holes or blemishes with a commercial filler, then smooth the deck and paneling with 150-180 grit sandpaper. Wipe down with a clean cloth dipped in mineral spirits to temporarily highlight any sanding marks. Smooth out flaws, then remove sanding residue with a tack cloth, compressed air or a brush. Apply the stain, let it dry and apply one of the recommended finishes of moisture-cure urethane, acid-curing Swedish finish or lacquer. When the first coat is dry, sand, stain and coat again. Repeat this cycle three times to achieve a brilliant, moisture-resistant finish.

6. Insert the Tub--Prepare the tub for insertion and connect all plumbing fixtures. Use industrial caulking to seal the tub to the deck surface, making sure that any potential leakage point is properly sealed.

QuickTips

Deciding Which Way to Go

Consider the advantages of both pre-finished and site-finished products when deciding which to use for your bathroom floor, tub surround, cabinetry and mouldings:

Pre-Finishing--Pre-finished hardwoods are recommended for many bathroom applications because their shop-quality finishes are both attractive and highly moisture-resistant. While these products may have a higher initial cost, they are less demanding in terms of worker skill level and work-site preparation. Most bathroom cabinetry is installed pre-finished because of the intricacies involved in cabinet making. Pre-finished hardwood flooring, mouldings, doors and paneling can be purchased off-the-shelf or, for larger budgets, custom-milled and finished to your specifications.

Site-Finishing--This method is still preferred by many builders because of the lower material cost and the higher degree of project control. The recent progress in water-resistant finishes has made site-finishing an increasingly popular alternative for major bathroom applications, such as built-ins and tub surrounds, as well as flooring and millwork.

Choosing the Right Species

Not all North American hardwood species react alike in humid conditions. The following species are favored for bathroom applications because they are especially moisture-stable, strong, hard, durable, and shock-resistant:

Oak

Maple

Cherry

Ash

Walnut

Hickory

Technical assistance and/or photos provided by: Allegheny Millwork & Lumber Co., Pittsburgh, Pa; Kohler Co., Kohler, Wis.; The National Kitchen & Bath Association, Hackettstown, N.J.; Plain & Fancy Custom Cabinetry, Schaefferstown, Pa.; and Sunrise Specialty Co., Emeryville, Calif. � 1999 The Hardwood Council

Reprinted with permission from The Hardwood Council website.