Is This Fan Explosion Proof?

The electrical code references a range of safety ratings for spray booth fans, which relate to the classifications of hazards and the rules for fan location and control switching. November 16, 2011

Question

How do you tell if a motor is explosion proof? I have a Binks booth with a tube axial fan. Would the motor be explosion proof? I just bought it a week ago (used) and put it together but now it looks like I will be moving soon so I don't want to hack a 24" hole in the ceiling that I have to fix. I would still like to use it for a couple months to get rid of the overspray if I can.

Forum Responses

(Finishing Forum)

From contributor G:

Look in the name plate. It will tell you if it is.

From the original questioner:

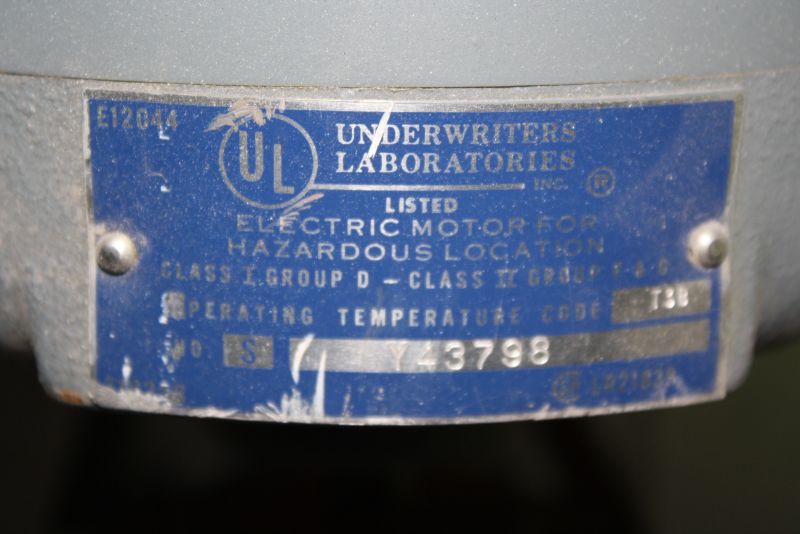

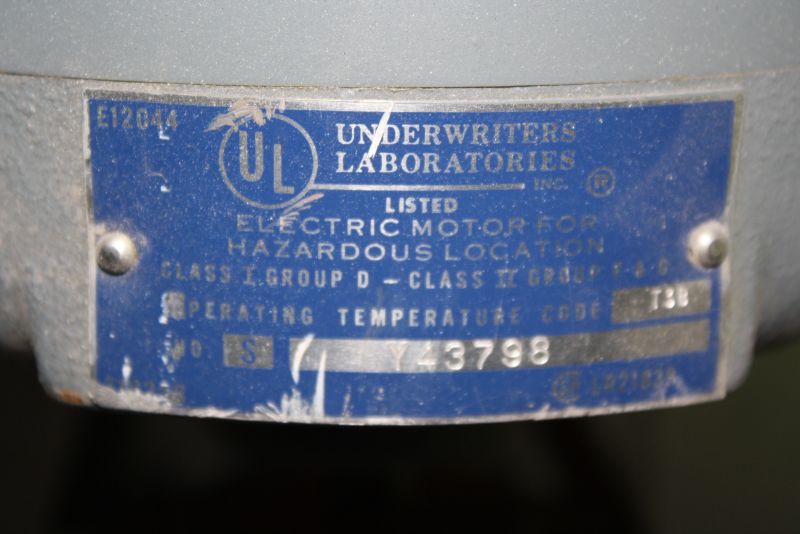

I took some pics. It doesn’t say explosion proof but it says hazardous location motor.

Click here for higher quality, full size image

Click here for higher quality, full size image

From contributor O:

Hazardous location is not equal to explosion proof. Also, explosion proof has subcategories with regard to the atmosphere (the explosive or flammable material it is proofed against). Is the motor inside the 'booth'? (in the atmosphere)? Check with whatever agency regulates spray booths in your state/city and see if the code requires explosion proof, if the motor is not mounted in the booth. If it is mounted in the booth you need explosion proof and rated for the solvents you use.

From contributor R:

It's outside your booth, doesn't need to be explosion proof. You are spraying inside your booth, aren't you?

From contributor H:

Here is the key to the puzzle. Where is says class, it says 2. To be explosion proof, it must say class one, division one. I believe what you have is a totally enclosed fan cooled motor known as a TEFC motor. As long as the fan motor is outside the airflow you can use either an open, TEFC, or exp proof motor.

From the original questioner:

My Motor is class 1 group D. What I can tell from reading online it looks like it's explosion proof for lacquers and solvents which is what I am using. I am still not 100% and would like someone to confirm.

From Paul Snyder, forum technical advisor:

Your motor is rated for Class I and Class II. Class I is flammable gases and vapors and Class II is flammable dust. Group D includes the solvents often used in solvent based finishes. Group F and G are dusts that can be explosive under the right conditions.

From contributor F:

Paul has it right. Your motor is the correct one for the application. It is a hazardous location motor and it is not located in the airstream. I have a very similar setup and all I can tell you is take good care of the motor as they are very expensive to replace or repair. Just replacing the bearings requires having the motor inspected (at least in my state) for a substantial fee. My question would be: Is there really such a thing as an explosion proof motor? I've heard the saying used often, but all I've ever found are different classes of hazardous location motors.

From contributor E:

The group is right fire code requires that if the fan is within the spray area it needs to be explosion proof. Since your fan is a tubular-axial it should be out of the critical bubble area. Depending upon if the booth is air interlocked that distance can vary from a max of 20' midpoint from the end of the booth or 10 ' midpoint from the front end (10' back or 5' back). What you do not want is to have to comply with a Class 1 division 2 explosion proof requirement. The last time I had to comply with that requirement it ran over $10K for switches, sealed wiring and motor.

From contributor O:

The real world is the codes as written in NFPA book 33. The motor is on top of the spray booth mounted on the sealer fan housing. The fan is more than three feet from the opening of the booth. Interlock the compressed air for the spray equipment so the fan must be on to have compressed air to the spray equipment. Then the wiring to the motor is only without Class 1 installation. If you do not interlock the compressed air feed with a venting (3 way air solenoid) then the code (say 20 feet) from the face of the booth must be explosion proof. Look at the lighting in the booth too. That must meet code too. Interlocks are the way to go.