Large "Bubbles" that Appear when Inferior Plywood is Finished

Plywood grading is based on the top ply's visual appearance, but low-quality core plys or manufacturing methods can create visible defects that show up only after finishing. March 26, 2007

Question

I've finished a few game tables for a new customer. They are 3/4" maple ply cut out with a C&C machine into different shapes. The problem is these nickel sized bubbles in the veneer. Most of them are difficult to see until the sealer is applied. I looked at some pieces another shop had done for them and the bubbles seemed to grow larger over time. The customer insists this is grade "B" material and that the problem is something with the finishing process. (Finishing schedule: oil base stain, vinyl sealer, pre-cat, sanding in between coats.) Any advice?

Forum Responses

(Finishing Forum)

From contributor G:

Most of the times I've seen this, it was caused by contact cement-applied veneer, not plywood. The solvents in the stain will attack contact cement. Is this plywood a new product that you haven't used before? Have you ever finished any of it before? Have you tried heating the bubbles to see if they will stick back down?

From the original questioner:

Yes, this is the first batch of tables I have finished for them. However, this plywood looks just like all the rest I've seen. We have finished plenty of shelves made out of what appears to be the same stuff, for various other projects. No, we did not try heating them, although I'm going to try that ASAP. We had been puncturing them and gluing them down with a syringe - big hassle. I'm starting to have a bad feeling about this job.

From contributor G:

Is this plywood, by any chance, not a North American product?

From contributor R:

Veneer bubbles are a panel construction problem, not a finish problem. Try a higher grade panel.

From contributor O:

Is the plywood you are finishing being supplied to you by this customer? If so, this is not an issue for you to have to deal with - after all, you are just finishing them. If you are supplying the plywood and doing the machine work and the finishing, then you will have to deal with the wood issues, and the customers issue.

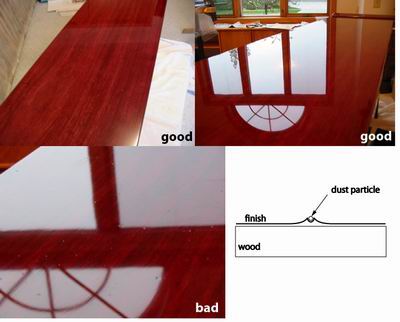

Today's plywood pretty much sucks. The veneers themselves are tissue paper thin, but more importantly, the underlayment is even worse than ever. What you're seeing in the form of a bubble is actually a knothole that's missing the knot. The veneer is laid up over this hole and the depressions show up after a finish coat is applied.

You have a couple of choices here. First, to completely eliminate the problem of any void in the substrate regardless of what wood species is used, use MDF (now you have issues with the edges). Second, find a supplier that handles a lumber core veneer. With this type of plywood, you're less likely to have this problem. Third, and probably out of the question, is to use solid material. The grading of lumber, plywood included, is based on the quality of the face veneers, and really has nothing to do with what it's laid up on.

I find it rather interesting that this new customer has had other shops do work for them. Why are they not working for them anymore? Sounds to me as if they want a 1967 bottle of BV Estate Cabernet wine, yet they barely have enough for a half pint of Ripple.

I hope you and your customer can come to an arrangement that benefits the both of you. It's nice to start off the New Year with a new customer, especially one that's happy.

From contributor W:

I'm like the others - I believe it's the wood veneer product used. It's the solvents in the sealer and pre-cat that's reacting to the adhesive and leaching through the veneer to raise it in places, maybe in the knot areas as suggested. There may be one solution other than changing wood materials, if customer is totally against that, and that is using a water base finishing schedule. Use water stain, water base sealer and topcoat. May work. I've seen it happen before.

From contributor B:

I agree with the other comments. Unless the veneer is applied with contact cement, the finish should not be causing the problem. It is probably a void in the substrate. In my day, no one ever boasted about using a "B" grade panel. Being a "B" meant that it simply wasn't good enough to be an "A", "AA", or "AAA". You buy B and you get B.

From contributor A:

These days, I always figure that when I say B, they misunderstand me and send me C. So lately I order A and they accordingly ship B. I haven't needed any A lately, but when I need it, I guess I'll order Z.

From contributor T:

I'll bet that those bubbles were there before any solvent touched them, they just didn't show up until some shine went on. Unfortunately, at that point, heating the spots in hope of adhering the bubble may damage the finish. I also have had to puncture these bubbles with a glue syringe, placing pressure and touching up (big hassle). If I were starting from scratch, I'd wipe the plywood down with mineral spirits or naphtha to shine it up, and look for any defects.

I recently had to insist on MDF for a painted kitchen's finished ends because the plywood was so full of voids and grooves that I couldn't level it out. We used to get shop grade birch plywood that was pretty enough to finish for the exteriors, but the stuff we get now embarrasses me to even be the interiors.

From the original questioner:

Thank you all for the prompt responses. To answer one key question, no, we are not supplying wood or doing any machine work - finishing only. Thanks again for the information on plywood. I worked for so many years in finish shops where there was no time for questions. It was just "Get it done, figure it out, we got to deliver this thing!"

From contributor S:

If you have any of the panels that are not finished, try a bright light at a low angle to see if the bubbles are already there. I had a job one time where they said our water stain was causing the veneer to fail and I checked one before we did anything and sure enough, the problem was already there. I try to inspect everything with a bright light before I even sand.

From contributor S:

Also tap with your finger on any areas that look suspicious. Where the veneer is not glued properly, it will sound dead or different than where it is glued solidly.