Loosening Seized-Up Machinery

It ain't no use if you ain't got the juice. April 21, 2011

Question

I have a SCM T110 spindle moulder, probably a 1980ís or 90ís model. I cannot raise the spindle, is very stiff to point of jamming. I can lower it but when raising again it gets to a position where it becomes too stiff again. I have lubricated and itís no better. Iím wondering if there is a problem with the rack and gear or some other reason. It's stuck less than half way up and has been up fully very recently without problems. It has been stiff in the past and freed with lubrication, but more stubborn this time.

Forum Responses

(Solid Wood Machining Forum)

From contributor H:

Take it apart and clean it out. It sounds like a chip in the system. I'd flood it with WD40 (a cleaner not an oil) then blow it out with compressed air and re-lubricate after. If that doesn't work it's time to take the whole thing apart. I am guessing it can be fixed.

From the original questioner:

Chip sounds likely. It feels a hard slightly squashy resistance when turning the height adjust wheel. I will post the outcome.

From the original questioner:

Resolution - I had given the spindle a fairly liberal spray of WD40 in the evening. The next morning, a colleague wound the height adjust wheel down a bit then raised it, possibly using a bit more pressure than I had dared to the evening before, and the spindle was freed. So I saved a lot of time not requiring a dismantle. Thereís plenty of oil and it elevates easily now. The earlier jam was probably due to a chip which was able to be compressed or squeezed out.

From contributor R:

Still might be worth taking apart. Greases dry out and absorb dust. Too much WD40 over time turns into a sticky mess as well. Taking it apart, giving it a good cleaning and re-lub will make you think you have a new machine!

From contributor J:

Just a side note, WD40 is a great lubricant, but keep in mind that if you move the spindle up and down a lot the degreasing agents in WD40 may cause more problems than good. The degreasers will strip away all other lubricants on the threads, whether it be grease or anything else. Then the WD40 will dissipate over time and you will end up with rust.

From contributor D:

I second about WD-40 and rust. Years ago the U.S. Navy came to the same conclusion and discontinued its use. A comparison of break free chemicals was done on all the commercial products like Liquid Wrench, Power Blaster, etc. Essentially the torque required to break scientifically seized fittings dry were around 350 ft/lbs., with different compounds reducing it to 250-150 lbs. Interestingly, the best performing compound was a homemade 50/50 mixture of automatic transmission fluid and acetone.

From the original questioner:

Anyway, I dribbled some left over automatic gearbox oil around the spindle. It seemed to be about the right viscosity, and easy to apply with the flexible nozzle. Regarding the WD40, I am forever spraying it into the sliding table bearings and onto the fence bar of my panel saw. So it looks like I had better find something else. Thanks for the tips. By the way, I don't really like using grease in exposed areas due to dust and chip attraction.

From the original questioner:

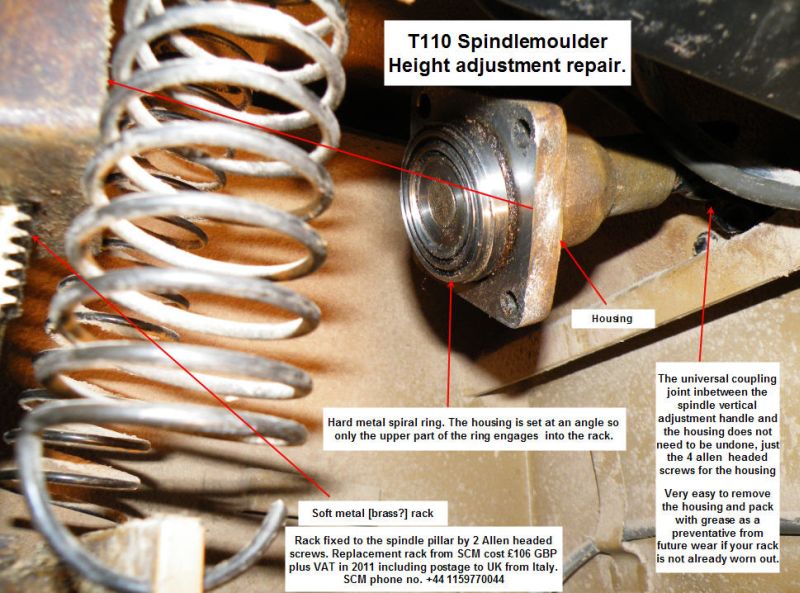

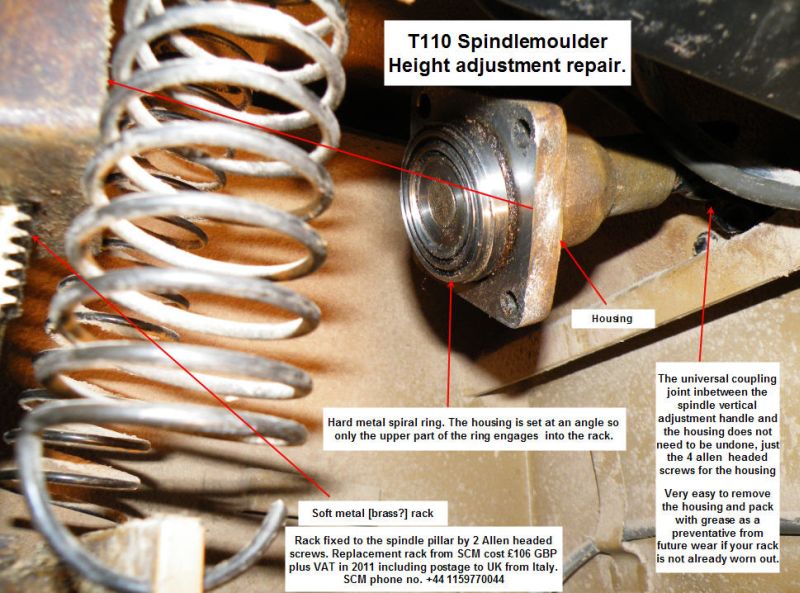

It jammed again, this time I undid the height adjuster housing and discovered the brass rack has broken teeth. See the photos below.

Click here for higher quality, full size image

Click here for higher quality, full size image