Machining Curves in Hardwood

Quick advice about tool choices and tool paths when machining solid Oak on the CNC router. April 30, 2009

Question

We're getting into tooling some complex shapes out of red oak blanks. I've figured on cutting the profile first, then the perimeter cuts. Most perimeter cuts are made with roughing then finishing one side at a time. But in the longer curves the tool goes into different grain directions along the same line. We're figuring by using counterclockwise rotation and opposite tool directions we can get cleaner cuts without tear-out. Has anyone tried a similar approach?

Forum Responses

(CNC Forum)

From contributor L:

I have found when cutting solid woods that conventional direction is the way to go. For the perimeter cuts use a down shear with multiple passes. A clockwise tool will not work running counter clockwise.

From contributor H:

We cut multiple passes. It takes more time, but pretty much guarantees a clean cut with no tear out. First we climb cut and then run the same path in the opposite direction doing the conventional cut. The conventional cut will clean away any fuzz left from the first pass, while not taking enough material to create chipout. For your profiling I would suggest doing a perimeter cutout pass first, just not all the way through. This will give clearance for the profiling bit so it is under less stress. The last thing you probably want to do is break a profile bit.

From the original questioner:

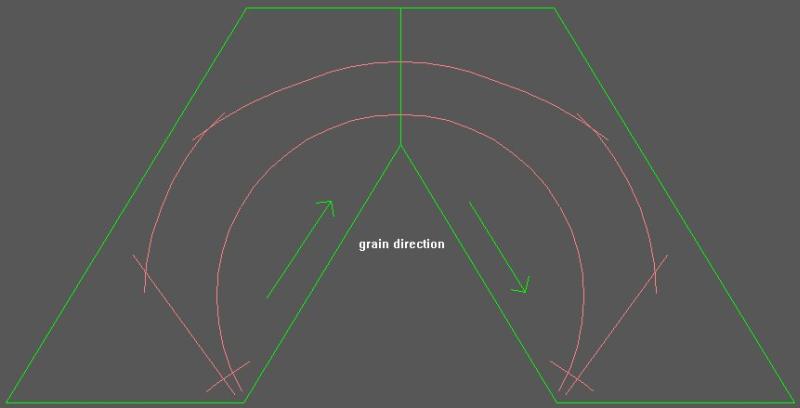

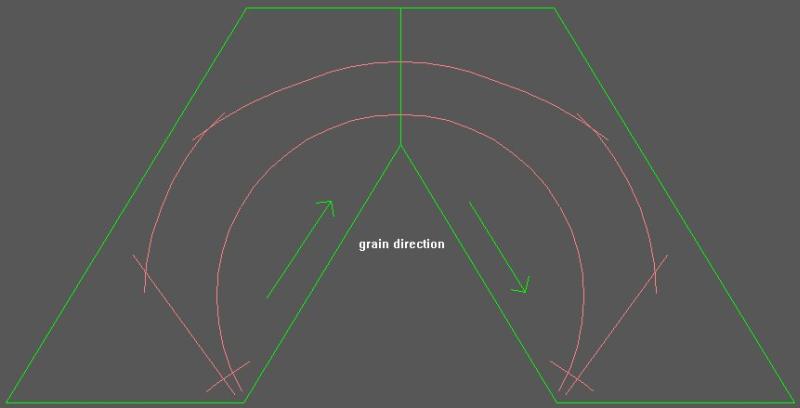

This is a more severe example of the situation. I'm not sure if I should break the arcs in half and go opposite directions with left handed tools. Or go counterclockwise all the way around with right handed tools and rough passes before finish pass?

Click here for higher quality, full size image

"Photo by Ethan Haar".

From contributor H:

That image shows exactly the type of work we do regularly in all types of wood, as described in my above post.

From the original questioner:

So your rough passes are clockwise, do you leave a little material for the finish pass? And do you break up the sides as I have done? I am impressed with your output, so I do value your opinion.

From contributor H:

Yes and no as to leaving a bit of material on the first clockwise (climb) pass. We don't program a stepped offset for the first pass, but we do end up with one because we hold our wood parts on vacuum pods. There is always about a .015" to .02" shift of the material on the pods on that first climb cut pass. By climb cutting this shift is away from the bit, thus making the part slightly oversized. The second pass, which is counter clockwise (conventional) then removes that .015" to .02" of material leaving a nice finished surface.