Making a Full-Height Cabinet Fit

A full-ceiling-height refrigerator cabinet can be a bear to install, because you can't tip it up (the diagonal is too long). Here's a useful thread on solving that problem. January 20, 2007

Question

I know there is a formula for finding the tallest you can build full length cabinets, but I can't find it. I have a refrigerator cabinet that is going to be full length with crown molding at the top. I need to build this the highest I can with minimal open space at the top so the crown covers the gap. Does anybody have a special way to do these? I have never run into this problem. I guess I've been lucky and had open soffits and 10' ceilings.

Forum Responses

(Cabinetmaking Forum)

From contributor H:

The formula for finding the diagonal is: The square root of the hypotenuse equals the sum of the square of the other two sides. The hypotenuse is the diagonal. But why don't you make a separate toekick, install in place, and then lift the finished cabinet with crown onto it? Or pre-fit the crown, leaving 1/4" ceiling clearance and then jack up base till it hits ceiling and skin over base with a finished panel? You cannot lift a cabinet into place without some clearance, so the hypotenuse formula won't help in this case.

From contributor B:

Is the fridge cabinet the end of the run or do you have base cabinets on both sides of it? If you've got cabinets on both sides, you can knock off the back corners so you can stand it up. Think outside the box and see if there isn't some way to make it work.

From the original questioner:

It is the end of the run and I only have base cabinets adjoining it. I thought about lopping some of the back corners off. This is for a refrigerator cabinet, so I don't know what you mean about the toe kick. I do have a utility cabinet full height in this kitchen as well and that does have a toe kick, so that is not a problem, but the refrigerator runs all the way to the floor. In thinking out of the box, can I build this on site? That is, build it disassembled then assemble on site. I'm thinking that I can fudge this in place piece by piece instead of as a whole unit…?

From contributor M:

I did one like this recently and built it in three pieces - two tall ends x 2" wide and the center cabinet section. The ends only have to be slightly less that 8' to stand them up at only 2" wide. I put cleats in the end panels to support the center cabinet and make assembly easy.

From contributor I:

It took me a long time to find/figure out the formula that you're talking about. It just so happens that I was sitting at a friend's work at 3 am one day and it hit me.

The normal Pythagorean Theorem is A squared + B squared = C Squared.

But in this case, you do it in the reverse:

C squared - B squared = A squared.

A squared is the tallest cabinet you can put into a room and have it rub the ceiling as you're tipping it up. Of course, this would be in a perfect world, so make sure you deduct a little from the number you get.

Example: If you have 96" tall ceilings, this is your C squared. You need to know the width or depth, whichever is smaller and can't change. That is your B squared. Your A squared is the tallest cabinet you can put into a room knowing the ceiling height and the width or depth of the cabinet and choosing the smaller of the two dimensions.

Let's say that 24" is your depth and your width is 36" wide. You would pick the 24" and the formula works out like this.

C squared= 96x96= 9216

B squared= 24x24= 576

Then to find the tallest cabinet you can put into that room, A squared, you do the following:

9216 – 576 = 8640

Take the 8640 number and hit the square root button. It will give you the following: 92.951... or 92-31/32, so just over 92-15/16". That dimension is the tallest cabinet you can put into that room knowing the above facts.

From the original questioner:

Yes, that does help and according to your theorem, I am 15/16 off, which I can work with. I took the 23 1/4" x 94" sheet over to see if I could make it fit somehow and I was off by a little. I could do it if I assembled on site, but would rather not. So thank you - I hope it works.

From contributor V:

For as often as you'll need it, don't agonize over the Pythagorean Theorem. It's great to use if you know it, but I don't think you need it here. It's a lot of brain drain for this. No disrespect - I've used PT for years in framing and layout prior to cabinet work, but I think the questioner is just looking for a quick number to work with. Try this - you can find your approximate minimum height in the time it'll take you to read this post. Go find your triangle drafting ruler. Draw 2 vertical lines scaled to the diameter of your smallest dimension in this cab. Have a base line and from one corner at 0, follow a diagonal up to 8' on the other line and mark it. Then scale straight vertically to get the height. It's pretty painless that way. It's not nearly as accurate, but I think you're only trying to get this thing in the hole at this point.

By the way, have you ever tried to negotiate a 7' 9" cabinet through someone's house before? My vote is for the site assembly.

From contributor B:

Buy yourself a Construction Master calculator. Five key strokes and you have your C2, or your A2, or those circle calculations. I keep one in the shop and one in the office. Use 'em all the time.

From contributor O:

Build it in 2 pieces - the bottom piece to house the refrigerator and the other on top 3/4" deeper than your standard upper (13" or so), then make the difference in the depth of the bottom piece and the top piece a top. Put some 1/4" material on it, then trim top edge of bottom unit with a nice trim. I think it looks nicer than 1 big deep cabinet. Also, it is how I built my own personal cabinet not so heavy. I make the top piece 3/4 deeper than the upper that it is butting into so I can put a route on that edge, and when crown is put on, it adds a little flare.

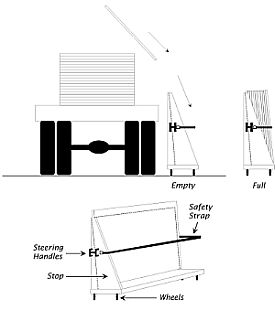

From contributor G:

I've done a few of these cabs. I build them 4 1/2" shorter than the ceiling height, then use a piece 3 1/2" tall under the cabinet. I use a plate on the inside of the cabinet to hold them together. Then I put 4" base trim around the bottom of the cabinet.

From contributor I:

Can you describe the plate you use on the inside of the cabinet? I'm thinking it is basically a 3 1/2" 3 sided plate form. Is that correct?

From contributor G:

I rip a piece of 3/4" ply 3 1/2" wide and put a piece of 2" face frame material on the front of it. On the inside of the cabinet, I use a piece of 6" wide 3/4" ply and screw it to the foot and to the cabinet side.

From contributor L:

One of the quickest ways to determine the highest sides you can stand up, is to lay it out on a piece of ply or the top of your work bench. Remember to include the thickness of the face frame.