Question

I have a sample door that was stained in a lacquer base stain and finished with a pre-cat lacquer that is several years old. I would like to match this color with a water base stain and top coat. I am working with an M.L. Campbell distributor to color match this sample. He is able to get close to the color except we are not able to get the dark definitions in the grain that the pigments leave once the stain is wiped off. My distributor tells me that the pigments in the waterbase will not stay in the grain the same way as the solvent based pigments stay in the grain. Has anyone else run into this situation, and if so how were you able to solve it?

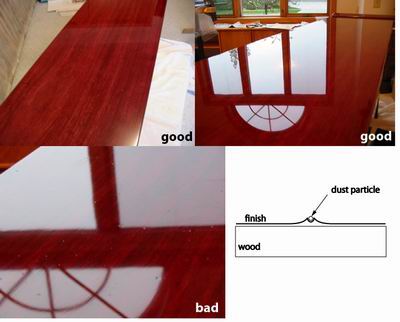

We are using MLC WS29WB10 stain base and P&L Glycol 844 colorants. The wood is birch and is sanded to 220, the stain is sprayed on and let set approximately 20 - 30 seconds and then wiped off. The customer really likes the way the darker areas of the door make the color stand out. Here is a picture of the door.

Forum Responses

(Finishing Forum)

From contributor R:

Ask your MLC distributor to cut down on the amount of P&L colorant and add more water borne dye concentrate to develop your stain color in the WS2WB29 stain base. It will allow the WB stain base to dive into the wood more. That base will allow you to get very rich colors just like solvent if you use MLC dyes in it. The only real issue is it stains more evenly than typical solvent stains if you are doing a match. Normally, even application with WB29 stain is a big advantage on maple and cherry to prevent blotching. I like sanding with 220 to cut down on any grain raise, but you might also try 150-180 grit before you put on the stain to open the grain more. Hope that helps you.

Contributor K - I had some General Finish samples from another job and I tried some of it on a piece of birch. You are right it produced a look that was much closer to what I was looking for. I started with the shaker maple and it was to red. Then I added some of their green dye stain to take some of the red out of it and I lost the reddish orange that I was trying to get. Not exactly sure which color to add to get from to red to orange-red, more trial and error I guess. I may have to pursue that further if I can't get the MLC to work. I was just trying to make it easy and get it locally, so much for that idea. The thing I didn't like about the General Finish stain is that it seemed to really raise the grain (much more than the MLC) and it is very thick (heavy bodied) and does not lend itself to being sprayed. The can just says wood stain, I don't know if they make it in a different base that would spray better and still look the same. I will call them and see.