Reprinted with permission from Jeff Jewitt of Homestead Finishing Products.

Copyright by Jeff Jewitt. Not reproducible in any form, written or electronic, without permission.

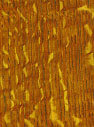

We do not sell Stickley stains. The factory uses a multi-step process using proprietary dyes; oil glazes and industrial solvent spray lacquer thatís typically beyond the scope of most home finishers. An alternative method which yields excellent results is based on the steps below and can be easily done by hand. Keep in mind there is no one-part stain in this process; you have to use two separate staining steps (except sample 6.) If you follow the steps below, you should have great results.

These finishing steps also introduce you to the technique of applying a glaze over a dyed surface. This technique allows for subtle manipulation of the overall color by choosing different glaze colors. We'll suggest starting formulas, but feel free to experiment. When you order, just tell us the sample color number you like and weíll sell you the products you need.

Preparation

The factory uses quarter-sawn white oak for all its Mission Furniture. If you use something different it will not look like the factory finish or the samples below. Itís not wrong to use a different wood, but keep that in mind.

After completing the building process, sand the wood with 100, then 120 and then 150 grit and wipe the wood with distilled water. Sand with 180 grit when dry and remove all the dust from the pores. You can use a shop vacuum or blow the dust off with compressed air. The pores must be clean and free of all sawdust before proceeding, so check the surfaces carefully.

Step One - Staining

You can leave the wood unstained if you wish, which produces the look in Sample 6. Most Stickley colors are achieved by applying dye to establish the dominant undertone of the piece. This can range anywhere from a light tan color to a dark brown. Order the TransTint wood dye color in the color you like. A 2 oz bottle makes at least 2 quarts stain. It's important to experiment on scraps and carry the finish all the way to the end. When applying by hand, we suggest using water only to thin the concentrated TransTint. Apply the dye by flooding all surfaces and blot up the excess. Let it dry 8 hours before scuff sanding with 320 grit sandpaper followed by a light rubbing with maroon synthetic steel wool. When the piece has dried, you may notice a lighter color to the pores. This is normal when using water dyes.

Step Two - Sealing

Apply one coat of General Finishes SealACell Sealer. Let it dry 12 hours, then lightly sand with 320 grit sandpaper. Be careful not to sand so hard you cut through the stain.

Step Three Ė Re-Staining (Glazing)

Apply the glaze with a stiff bristle brush, working it across the grain to make sure it gets into the pores. Wipe the excess off with a dry rag. If the color is too dark, or it dries quickly, apply some mineral spirits to the rag to help remove the stain. Thinning the product with some mineral spirits or boiled linseed oil (about 3 tablespoons boiled linseed oil per cup of stain) will extend the working time. Let the stain dry at least 24 - 48 hours. To check if the stain is dry enough to topcoat, wipe it with a dry cloth. No stain should come off.

Step Four - Finish

A mission finish on oak looks best with as little finish as possible, and it should not be glossy, but tastes vary so thatís up to you. I like at least two coats of General Finishes ArmRSeal Satin Finish Ė applied with a soft cloth. An alternative to the General Finishes Product is satin spray lacquer, but you should substitute lacquer sanding sealer for the SealACell.

Stain with TransTint Dark Vintage Maple diluted at 1 oz dye to 2 qt. water.

Apply one coat General Finishes SealACell Sealer. Let dry one day and scuff sand with 320 grit.

Apply General Finishes Antique Walnut Gel Stain. Wipe clean and let dry overnight.

Apply 2 coats General Finishes ArmRSeal Satin Finish.

Stain with TransTint Reddish Brown * diluted at 1 oz dye to 1 qt. water.

Apply one coat SealACell Sealer. Let dry one day and scuff sand with 320 grit.

Apply General Finishes Georgian Cherry Gel Stain. Wipe clean and let dry overnight.

Apply 2 coats ArmRSeal Satin Finish.

Stain with TransTint Dark Mission Brown diluted at 1 oz dye to 1 qt. water.

Apply one coat General Finishes SealACell Sealer. Let dry one day and scuff sand with 320 grit.

Apply General Finishes Java Gel Stain. Wipe clean and let dry overnight.

Apply 2 coats General Finishes ArmRSeal Satin Finish.

* To produce the "Oak Park" color, use Dark Mission Brown mixed at the ratio of 1 oz dye to 2 qt water. Use General Finishes Brown Mahogany Gel Stain.

Stain with TransTint Brown Mahogany diluted at 1 oz dye to 2 qt.* water.

Apply one coat General Finishes SealACell Sealer. Let dry one day and scuff sand with 320 grit.

Apply General Finishes Candlelite Gel Stain. Wipe clean and let dry overnight.

Apply 2 coats General Finishes ArmRSeal Satin Finish.

* 1 oz to 1 qt water produces color similar to "Onondaga" Finish

Stain with TransTint Medium Brown diluted at 1 oz dye to 1 qt. water.

Apply one coat General Finishes SealACell Sealer. Let dry one day and scuff sand with 320 grit.

Apply General Finishes Nutmeg Walnut Gel Stain. Wipe clean and let dry overnight.

Apply 2 coats General Finishes ArmRSeal Satin Finish.

Apply one coat General Finishes SealACell Sealer to the unstained wood. Let dry one day and scuff sand with 320 grit.

Examine next to a sample of the Factory Limestone if matching. It may be pretty close without the next step.

Apply General Finishes New Pine Gel Stain. Wipe clean and let dry overnight.

Apply 2 coats General Finishes ArmRSeal Satin Finish.

The finishing products used above and samples are not the products used by the Stickley factory. The use of the Stickley Finish names is used with the permission of L. & J.G. Stickley Inc.

Reprinted with permission from Jeff Jewitt of Homestead Finishing Products.

Copyright by Jeff Jewitt. Not reproducible in any form, written or electronic, without permission.