Modifications Cure Woodmaster 718 Chatter

Pictures, descriptions, and accounts of changes resulting in a finish as smooth as a baby's... well, you know. February 27, 2005

Question

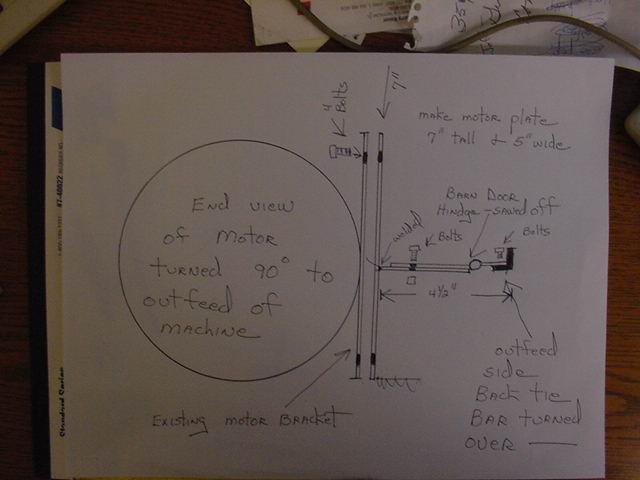

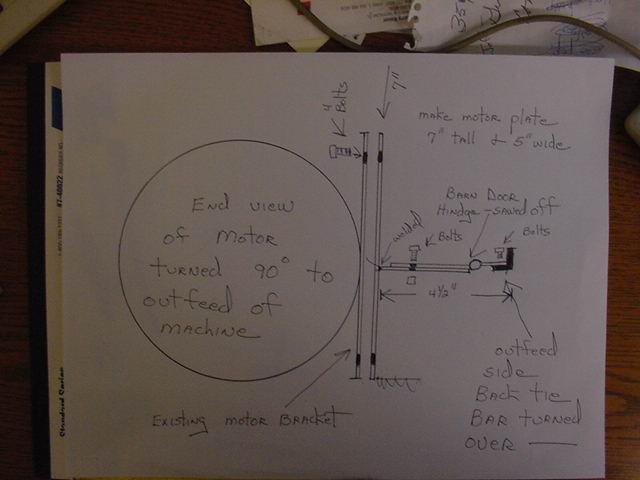

Here is a picture of the mod that I did to my Woodmaster 718. This mod cures the chatter problem I was having. The moulding is coming out nice and smooth. No sanding required. Stain grade all the way.

Click here for full size image

Forum Responses

(Solid Wood Machining Forum)

From contributor A:

I have been modifying my WM 18 ever since I bought it. It's a great machine if you tickle her right.

I read your last post and was interested in the outcome.

1. What size and type of hinge did you use?

2. Did you have any belt alignment issues? (Those powerplus belts need to be run dead straight or they chafe.)

3. Is the vibration nil?

4. Are you now running only one v-belt on a two belt machine?

5. Did you speed up the cutterhead?

I've been planning on bumping the speed up to 5500rpm from 4200 by changing the motor sheave to a 4" from the stock 3". I believe WM used the 4200 speed solely for the risk of flat back molding knives. Most planer/jointers run at 5000 to 5500. I, like you, use corrugated knives. I bought a couple of corrugated heads from RBI a couple of years ago and they are just the crackers.

One other modification you might consider is reinforcing the flimsy infeed/outfeed tables. I bonded 3/4" MDF to the undersides with polyurethane caulk. The difference is unbelievable.

I couldn't be happier with my "Ol Woodmaster."

From the original questioner:

Here are some of the specs. I just used an old barn door hinge and sawed it off so I wouldn't hit my leg on it. I'm using a single belt with the weight of the motor putting tension on the belt. Don't use two belts. Lack of tension and two belts are the major causes of chatter. I have considered speeding it up, but so far I haven't. May not be necessary.

Contributor A, the bed-board mod that you did is a great idea and helps stop tear out along with unsightly gouges in the wood. I did a similar mod on mine and found that increasing the feed roller tension a little also helped. However, I was still getting very fine chatter that, on stain grade moulding, stood out like a sore thumb - therefore, it all had to be sanded. This mod, so far, has ended all of that. Dual belts on this machine tend to fight each other, get hot, stretch, and set up vibration in the head. I think you won't have to tickle her anymore after you make this mod. I am very pleased with the quality now. I would still like to get her up to about 7000 RPM. Then you could run the feed rate wide open, which is about 16 or 17 FPM. That would be better than 40 to 60 percent.

Click here for full size image

Here's a top view. Use only a single belt.

Click here for full size image

From the original questioner:

Contributor A, forgot to tell you that speeding up the machine won't help unless you get rid of the head vibration. You will just have a lot of chatter quicker. I am simply removing the motor from a fixed mount, making a motor bracket with a hinge that allows the motor to go up and down, and uses the weight of the motor to apply tension to the belt. The motor will want to sag away from the pulley side, but you can loosen the bolts and jack it sideways to level it after installing the new mount. You only have to do this one time when you modify your machine, then it is set. Changing accessories is a breeze. Just lift the motor up, take off the belt, and do your thing.

My Woodmaster 718 now makes moulding as good as or maybe even better than a $50,000 machine. It just doesn't make it as fast.

I also forgot to mention that I drilled 4 new holes in the back of the machine and raised the tiebar 6 inches to shorten the length of belt needed. This helps to further reduce vibration, saves money buying less belt, and you don't have to bend over as far to raise up the motor.

You also need to run the type of belt that I have shown in the picture. This type of belt runs smoothly and greatly enhances your machine's performance.

From contributor A:

I completed the Woodmaster Powertwist V-Belt mod early this morning. I made my mods a little simpler than yours. I bought a 4" x 12" piano hinge and bolted it to a piece of scrap 1/4" x 12" x 12" 6061-T6 aluminum plate I had kicking around the shop. I left the tiebars in the original place and just bolted everything together. The extra length of the motor mounting plate coupled with a very stiff hinge allows you to use the standard 4' belt.

Like you mentioned in your original post, the results are unbelievable. There is an extreme difference in just planing. No chatter whatsoever at 16 ft/m.

By the way, I forgot to mention that I changed the feed speeds within the first week I got my machine. You basically change the three sizes of the feed sheaves and you end up at a top end of 32 ft/m. That is variable from 0-32 ft/m. The 5Hp motor will plane 1/8 of material at 30 ft/m. I'll measure the sheave sizes if you are interested...

From the original questioner:

Glad to hear that! I am very interested in any additional modifications that you have made or plan to make on your machine. Let me know how it moulds. Should do a beautiful job.

From contributor J:

Contributor A, I have a 725 and I have decreased the chatter problem by doing the original questioner's v-belt mod, but I still am not entirely pleased. The questioner liked the bedboard modification that you suggested. What was that modification? Another area of concern is the planer blades and moulding knives from Woodmaster. If they are not the best, who would you recommend that I buy from? Any other suggestions to improve my 725 would be greatly appreciated.

From the original questioner:

The problem with the bedboard that Woodmaster sells you as an option is that it doesn't lay flat on the metal bed of the planer. It's great in theory, but it, being loose, allows the boards to slap and move up and down. The feed rollers aren't strong enough to hold the board and the bedboard down at the same time. I made my bedboard out of a piece of 3/4" countertop scrap and it works fine. Or else, follow the Woodmaster book, and make your own bedboard. 3/4" flake board works great and will lay perfectly flat. I really don't think you need to glue it down, but it wouldn't hurt. Also, I removed the infeed and outfeed wing extensions that they send you because they can not be perfectly aligned with the planer bed. They further cause the plastic bed board to raise above the planer bed and cause your stock to slap and bang around, making gouges in the wood. Make your new bed board long enough to replace them. You can make nice moulding with a Woodmaster that needs no sanding, even with their single knives, but you just have to work on it a little. You have to modify the motor mounting and the bedboard to really see great results. You might also want to set your feed roller tension to the max that the book says and then some.

The comments below were added after this Forum discussion was archived as a Knowledge Base article (add your comment).

Comment from contributor A:

I have a Woodmaster 725 with an insert cutter that has lots of chatter. I removed one belt and the chatter was reduced. I changed to Link-Belt and it was worth every penny. It reduced the chatter even more but I can still feel slight vibration and after staining itís visible if you are fussy. Iím going to fabricate a hinged bracket that would allow the tension to be adjusted because I think the full weight of 7.5HP motor would be too much.