Muting the Grain on a Cherry Table

A furniture-maker needs to make a new cherry table match existing woodwork that has a washed-out grain. Finishers offer advice about formulas and application. July 11, 2005

Question

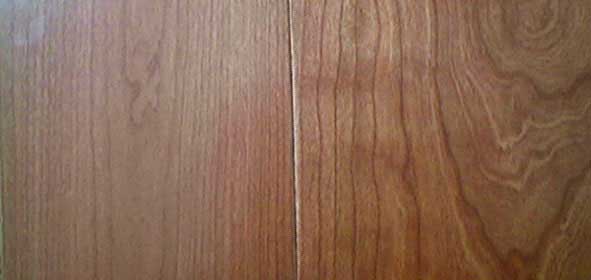

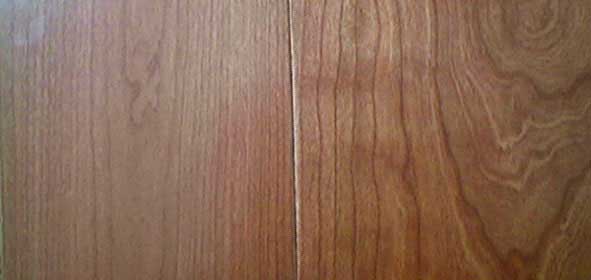

I've made a large receptionist desk for a client out of cherry plywood. He gave me a sample to match, and in the photo below it's on the left. I matched his sample, but he doesn't want to see the grain - he wants it muted to match some woodwork in his office. I've never had to lessen the grain in wood before. I'm using the Endoro line of water based stain and finish, so if there is a method to do this, it has to be compatible with the waterborne stain. Any help is appreciated.

Click here for full size image

Forum Responses

(Finishing Forum)

From contributor B:

Try using a stain after a wash coat so that the stain does not bite into the grain and accentuate it. Also, sometimes the type of clear coat can affect clarity. For example, low sheen topcoats will make the color look kind of milky, hiding the grain a little bit

From the original questioner:

I tried using a dye recently – J.E. It's a moser fruitwood pigment, and it didn’t work that well. I used water to mix the dye with. In the samples it went on kind of blotchy, and the stain over it came out very red and much too dark. The dye did make the grain less pronounced, but I don't know if I have time to find the right colored dye. I might have to convince the client that seeing the grain is not that bad. The problem is that the woodwork they have was finished in some way that the barley lets the grain show though. It does look like they painted it with a stain and did not wipe it off. Is there anything else I can try?

From Paul Snyder, forum technical advisor:

To the original questioner: Give this a try. Seal the wood with a coat of clear and sand smooth. Then mix 2 ounces of the stain into a quart of your finish and spray that over the sealed wood. This should make the coloring very even and mute the grain.

From contributor D:

To kill the grain, you first spray a diluted white toner on the wood. Then mix some dye in your next coats of clear to bring the color back, but the grain will still be somewhat killed.

From contributor T:

I would agree with Contributor D’s method. I approach this in a slightly different way, but the outcome should be the same. I mix white with pigment as close to the shade of color I want, or that the sample dictates and seal in. If further blending is necessary, I do it after the first seal coat. However you choose to do it , adding white is the way to get there.

From Paul Snyder, forum technical advisor:

To get very even coloring and mute the grain, stains like bleachtone or blond-it do a good job. These are spray only stains that go on the bare wood and establish a uniform base color that you can glaze, shade, or tone for color and effect. You can also add pigments to the bleachtone/blond-it for custom shades. And by thinning with the clear stain base, you can control the color intensity.

Looking at the color sample the customer provided (the left sample in Jonathan's picture), it's not clear if a equalizing stain (bleachtone/blond-it) was used on the wood. It has a lot of color in the right side of the sample, which makes me think the rest of it looks washed out because of the camera angle. If the entire sample does have that washed out look, then starting with the bleachtone or blond-it as Contributor D suggested is a good approach.

Adding a pigmented stain to the finish and spraying it over a sealed surface will have the same muting effect on the grain (it may take a few coats of the toner), but the wood won't be as uniform as it would be with a coat of the equalizing stain.

From the original questioner:

The photo of the sample is not the best - it was taken outside, and there was some glare on the customer’s sample. The lower right side is what the whole sample looks like.

I tried a few versions of the things suggested. I found a modified version of Paul’s first suggestion worked pretty well. I put on a coat of Enduro's sanding sealer, then sanded with 320 grit paper. Then I put on a full coat of stain. After the stain, I used a coat of shellac to get to the color I needed, then I used the satin finish. Sealing first seemed to even out the color, and the grain did not show through as much. Even though it looked okay on the sample board, I'm nervous to try this on the whole piece. I'm going to give the blond-it a try as well. Can I use the dye stain I have to color the blond-it? It's been mixed with water already.

From Paul Snyder, forum technical advisor:

To the original questioner: I don't think I'd start with the bleachtone/blond-it; there's too much natural color in your customer's sample to indicate this type of stain was used. And I would not color blond-it with dyes; that'll take away from it's muting effect.

The steps you describe; sealing, staining, and top coating sounds like a good approach. If it looks good on a large sample, it's a pretty straight forward approach that doesn't require a lot of specialized technique - unless you're playing around trying to wipe the stain just right to get the color you want. If so, adding the stain to you finish (thin the finish first to keep each coat thin) and spraying it will make the job easier.

From the original questioner:

Paul, I have a half a sheet left of the cherry plywood, and I'm going to use that like you said. Getting the color is not too hard, it's trying to mute the grain that's giving me problems. The job would have been so easy without this step.

From Paul Snyder, forum technical advisor:

To the original questioner: That is the blond-it stains I use, but WFS only has a few colors. The company that makes the blond-it stains is James B. Day. The bleachtone stain, like Mohawk, is solvent based and has to dry for a full day before you can topcoat it with water-base finish. The blond-it is water-base.

From contributor G:

To the original questioner: About putting on a full coat of stain - did you wipe it on or spray it? Paul is on target here with the spraying of the stain. By wiping, you push it into the grain thereby accentuating what you are trying to cover.

If spraying the stain on still does not solve your problem well enough, then tone your finish coat instead, as Paul has mentioned. This should be pretty easy for you once you get the hang of what you're doing.

Production cabinet finishers do just the process you are undertaking. For expediency sake they don't stain the wood directly, and some guys seal, spray stain, then top coat. Most guys doing average work just tone the top coat. It's why the grain on those production cabinets always seems a bit foggy.

From the original questioner:

To contributor G: I just did small sample boards which I brushed the stain on. I thought the sealer would prevent the stain from penetrating the wood? It did look like that. For the actual piece I can spray the stain on.I'm going to spray a sealer coat, spray a stain coat, and then spray the finish coats. In some samples, I'll try toning the first coat of finish.

From contributor K:

I also use Enduro and just had this same problem. I added some of their modifier to the stain which thickened it up and evened it out (it does lighten the color). I then mixed a little stain (no more than 10%) and some Cal tints pigment to some poly to help cover the grain – one or two light coats and then finished with clear coat.

From contributor C:

I would suggest trying a flesh colored toner (white with burnt sienna). This would be the base or background color. Thin your toner 50% - you do not want to block out the wood, you only want to uniform the woods, (you’re looking for translucency). Then apply a seal coat so your pink toner will not change when you staining, glazing, or using a shading stain. I would probably glaze and brush it out. Choose any one of coloring mediums you are familiar with. If you decide on a brown color, add a little yellow to mute the color in the grains.

From the original questioner:

After many sample boards, here is the formula I came up with:

• Enduro sanding sealer amber overprint.

• Enduro stain mix of light cherry and medium oak 3/1 parts.

• Second coat of Enduro stain mix.

• Amber tinted shellac.

• First coat of finish - satin Enduro with amber overprint mixed with stain mix 6/1 ratio.

• Second coat of finish, added more medium oak to increase the brown.

• Third coat of finish Enduro satin amber overprinted by itself.