Notching Cabinet Backs for Hanger Rails

Here's advice on routing out cabs for hanger systems, and a picture of a handy shaper jig. September 7, 2006

Question

For those of you who use the Blum or Camar cabinet suspension hangers, how do you approach notching out the end panels to accommodate the hanging rail? I used a router with straight bit to notch out a 10mm by 40mm gap with the cabinet flipped on its front. The results were not professional-looking, although it did the job.

Forum Responses

(Cabinetmaking Forum)

From contributor M:

Shaper dedicated to this task. It works well. The diameter of your cutter should allow you to set it up where all that is required is a straight move into the cutter, then pivot off. When set up like this, we could cycle 4-5 pairs a minute. A router table could accomplish the same task, but would not take the repeated force as well over time. It depends largely on the volume you are trying to set up to handle, but the shaper is in my opinion the best manual way to remove this.

From contributor A:

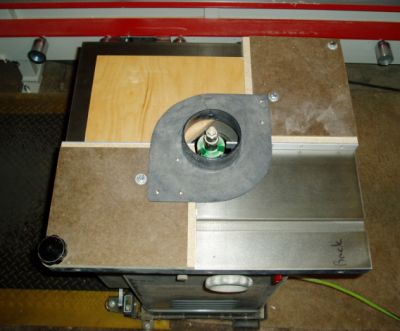

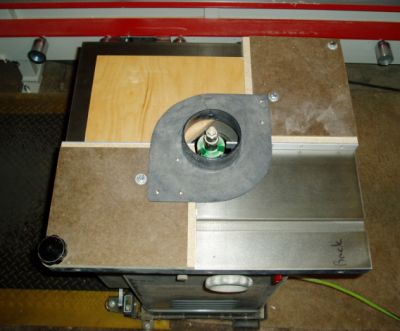

I use the Camar hanging system. All notching on the sides and backs is done on a cheap 1 ½ HP shaper with a 2” diameter x 1" high Grizzly shaper cutter with a 1/2" spindle. I think that I had a hard time finding this size cutter and I believe that it is important because you want the back notch to be completely hidden by the suspension block cover. It is set up with permanent fences so that I feed from one side for the cabinet sides and from the other for the backs. I have a notched piece of plywood that gets placed in the side that is not being used, to help with dust collection (see picture, hose removed for clarity). When I move to a bigger shop, I will make a larger table to go around the top to help support bigger panels.

From the original questioner:

Thanks for the responses. The picture was especially helpful - what a great jig design! Found a Knowledge Base article which has an excellent diagram for end and back panel notching:

Hanging Cabinet Doors