Pneumatic Clamps for Sliding Table Saws

Info on aftermarket and shop-built pneumatic setups for clamping material to a sliding table saw. March 26, 2009

Question

I am interested in setting up a hold down clamp for panels on my slider. If anyone has ideas of how to make one myself it would be appreciated. I want to activate the clamp at the head of the sliding table from the back of the saw before I start a long rip cut.

Forum Responses

(Cabinetmaking Forum)

From contributor M:

There is a guy on the Felder Owners Group that designed a set of clamps that go into the slider for this very purpose. They're called the "Big Squeeze" clamps. There is info on the site about ordering them. I have a pair and they work great. For the cost you wouldn't even want to try to make them yourself. A pair with a master/slave setup is around $650. A single clamp is less. They are very well made and well thought out.

The name of the company that now makes those clamps is Piranha Plastics. If you Google "big squeeze clamps" the first one that comes up is a tutorial of how to install them on a Felder by Best Woodworking, but the pictures aren't that great of the clamps themselves.

From contributor R:

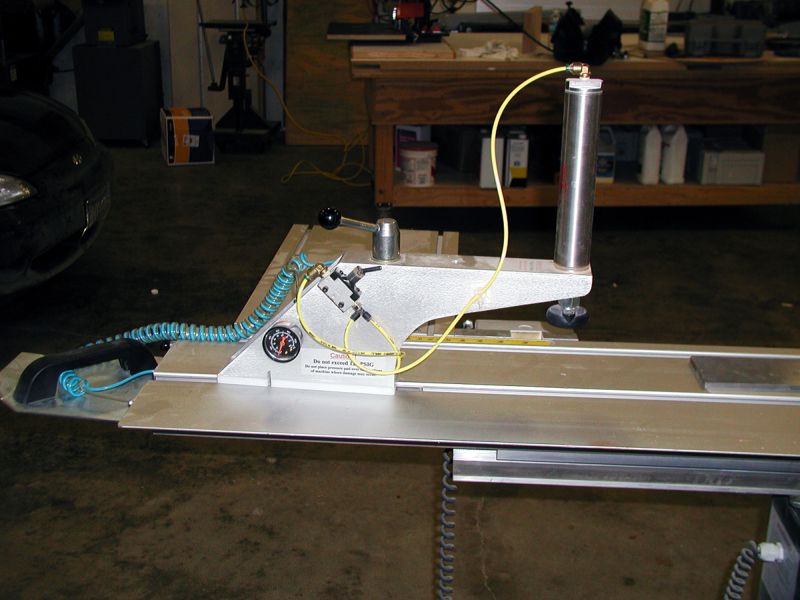

Here's a picture for you. Great clamps in my opinion.

Click here for higher quality, full size image

From contributor L:

Martin has a great clamp for sliders. Google "martin saw". Listed under T74 classic, accessories, "Pneumatic pressure bar clamps for sliding table," T7470-a.

From contributor J:

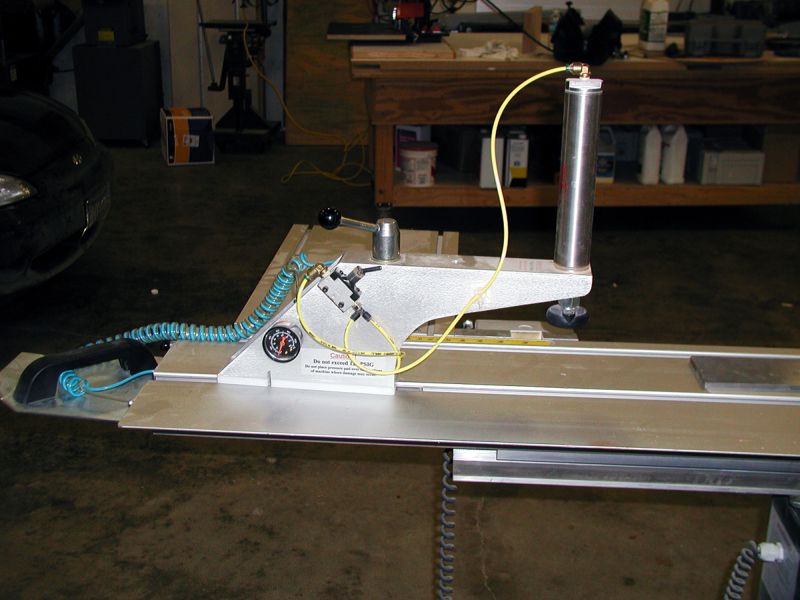

I built one myself for about $650.00 in materials. The nice thing about a full length clamp is that it holds warped panels flat and never needs adjusting. The beam is easily removable when not needed. I also installed an activation pole that runs the entire length.

Note: In the image below, the safety shield on the hold down beam mechanism has been removed for visual clarity.

Click here for higher quality, full size image

Photo courtesy of Progressive Wood Works Inc.

From contributor L:

Rube would be proud of you. I've got modifications to a lot of my stuff to make it do what I want also.

From the original questioner:

That's a great full length clamp, but I just need one hold down at the fence end of the slider to keep sheets stable. I cut sheet goods mostly.

From contributor R:

I made 2 for $30; 1-4', and 1-8'! Took some 1/4"x3"x3" steel, cut some hand holds in it, and buffed all the corners so it would "make nice" with the plywood. Crude but really fast, plus you get more exercise! :-)