Prepping MDF for Paint

A discussion of primers that can help machined edges of MDF panels accept paint the same as panel faces. December 30, 2005

Question

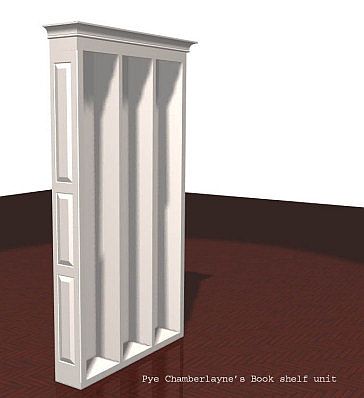

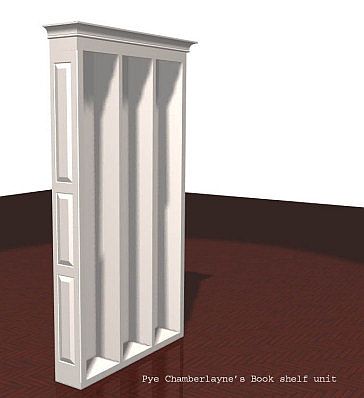

I drew the pictured bookcase in a CAD program. A friendly person in a forum related to the program added the crown molding hat (my CAD skills are a work in progress) and we built a pair of these cases facing each other across a six-foot wide, 12' long breezeway.

We used poplar for the uprights, 1/2" Baltic Birch for the backs, but for the panels we used MDF. We'd done MDF panels before that were beautifully machined but roughened up when primed with a water-based primer. They still looked OK, but smoother would have been nicer.

On this pair of cases we took the advice of a leading woodworking magazine and prepped the routed sloping sides of the panels with diluted wallboard joint compound, which we scraped and sanded. After we primed with an oil-based primer it took a finish coat very well. But we sure would like to avoid that joint compound step again. It was way too much work. Iím looking for a better idea for prepping MDF milled surfaces, maybe some high-solids oil-based primer that you have to stir often.

Another question - is there a forum that concentrates on MDF? My partner and I lost our fear of the stuff when we got a good dust control system, which we augment with masks and over-pressure bio-control hoods. We are controlling the material weight problem by building in units that are basically boxes that get attached to each other and face-framed.

Click here for full size image

Forum Responses

(Cabinetmaking Forum)

From contributor A:

There are a number of approaches.

Priming MDF Raised Panel Doors

From contributor B:

Use glue size - it is much easier to apply than the joint compound. Titebond sells a pre-mixed solution, or you can simply experiment with proportions of typical yellow glue and water.

From the original questioner:

Wouldnít the water in the glue raise what I am not quite willing to call the grain, but some of the fibers in the MDF milled surfaces? That raising occurred when we applied water-based primer to the milled surface before painting.

From contributor B:

If you sand the machined areas first with a very fine sanding sponge, then apply the glue size, then sand again with a sponge or paper after letting the glue size fully dry, the machined areas will take primer as well as the non-machined areas.

From contributor C:

Checkout your local Auto shop. I think the name brand is Feather Fill. It's a high solids primer that works great on MDF. Spray 2 to 3 coats, scuff, and apply just about any top coat.

From contributor A:

Are you doing only bookcases? By my reckoning those bookcases should take about a day to finish. How much faster do you want? As previously mentioned, sanding the milled surfaces saves a lot of time. The more you polish them, the less the primer will raise the fibers. Sand out any saw marks on the cut edges. Then polish the edges and the profiles. A 280 grit Sia pad works well for this. Iíve never found it necessary to size and it just seems to me to be an extra step.

After the first primer coat Ė I like Beckerís Bernyl Surfacer Ė a fine/medium sanding sponge is good to knock down the raised fibers in the profiles. A ROS with 220 grit will do the flat surfaces pretty quickly. Again, donít worry about sand-throughs. After the second primer coat, you should have a pretty smooth substrate. Topcoat as many times as you feel is right. On crown, I think that one topcoat is enough.

From contributor D:

Try Clawlock - one coat on the face, two on the end grain. It is fast drying, and almost anything sticks to it like grim death. It's the only way to go for me.

From contributor E:

MDF soaks up water like a sponge. It will grow 1/32 in thickness in a humid summer. Water based primers will raise the grain every time. If you are going to use a primer it must be solvent based like Clawlock or BIN white shellac primer. I like the shellac, because I use WB primers over it and it dries in 30 min.

From the original questioner:

I'll try to find some Clawlock. Feather Fill sounded like an ideal solution, but I can't find it at my local auto paint suppliers, Pep Boys or the like. I gather that it's a PPG product from a division called Ditzler. Googling for it quickly does not yield dealers. I would want it in a spray can I think. I don't have a good spray rig HVLP or regular air compressor rig.

In answer to one question, bookcases are not the only think we do. We do cabinets and furniture, too. We are retired folks, in our mid-sixties, supplementing our income with woodworking. We work slowly and we finish our projects by brush. My partner does most of the painting and it will have taken her about three days to prime and double-coat the pair of bookcases, one of which is shown above. Call it maybe 15 hours of work with a ten-minute break every hour or so.

From contributor F:

Clawlock is an ML Campbell product made originally for problem areas like MDF edges. It comes in black and white and can be tinted, and works great right out of the can using Kremlin or similar system. Buy it by the gallon. It is very high solids and unless you use a ton, mixing from the bottom of 5 gallon pail is a pain.

From contributor G:

I've just started using 2 parts water to 1 part yellow glue, mixed well. I put the solution in an empty contact solution bottle. The small opening in the bottle allows you to squeeze on the solution and follow with a disposable glue brush. I apply it once around the edges, then again to make sure I have covered it all. Let it dry and then sand with 220 by hand. You'll be able to tell when itís all set for primer/paint, after 2 coats usually, which you can apply easily in less than a day.

From contributor H:

Is there a way to correct the problem of rough surfaces on the MDF doors once they have already been painted and lacquered? Also, would the priming discussed here help avoid chipping around edges of MDF doors?

The comments below were added after this Forum discussion was archived as a Knowledge Base article (add your comment).

Comment from contributor I:

I have used Clawlock for years on cut MDF surfaces. I have also used vinyl spackling (light weight and heavy weight) and glue sizing. My current approach is to size with diluted wood glue first and then go to primer - Clawlock or other. I find that using only Clawlock I have to apply too many coats to get a finish that matches the factory finish MDF faces. Using the glue sizing first also seems like a more environmentally friendly approach.

Comment from contributor J:

We saw dramatic improvement in our paint area on door face edges after painting when we switched from MDF to HDF. The higher density seems to combat absorption of paint much better than MDF.

Comment from contributor K:

I just finished a floating shelf project I built from MDF. I used the glue sizing (1:1 white or yellow glue and water) and it worked awesome. It dries fast enough that it doesn't raise the particles in the MDF at all. Simply apply with a foam brush, let it dry, sand it with 220, prime, and paint. It will look exactly like the MDF flat surfaces.