Pricing a Nice Built-In Cabinet

In this detailed thread, a cabinetmaker learns that he is way, way under-pricing his work — and picks up some good business tips. August 22, 2007

Question

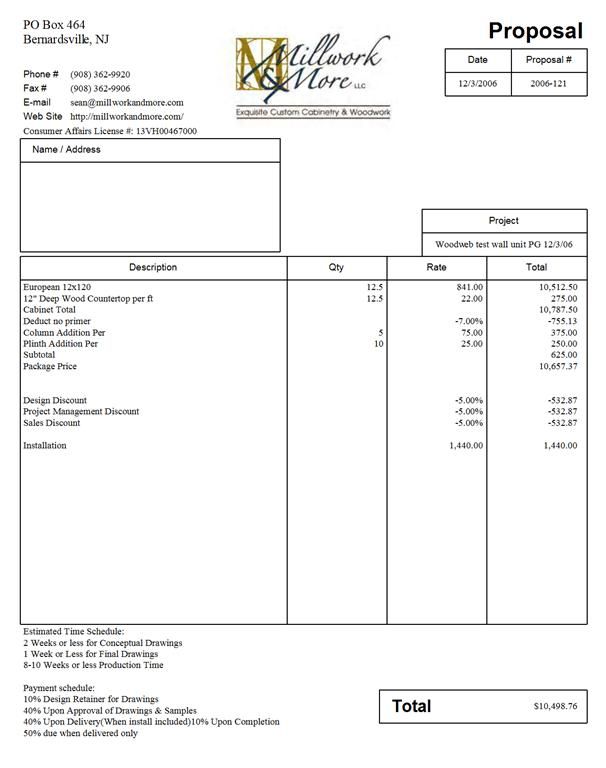

I charged this client $170.00 a linear foot for this built in. It's roughly 12 1/2' wide by 10' tall. All paint grade, poplar frames and Okoume ply and I do not have to paint it. Is that in line with what you guys are seeing? It's in Atlanta, Ga.

Click here for higher quality, full size image

Image created by Daniel Hebert

Forum Responses

(Cabinet and Millwork Installation Forum)

From contributor H:

A lot more... maybe 100% more for some of us. The painter will probably charge more than you did. You have at least 6-800 in material costs. Perhaps more. You're doing this for fun and spare pocket change, right? Take a business course at a local college.

From contributor M:

With a quick look at your drawing, I would be charging 6-7k for that job with painting and installation. Your client is getting a great deal, and you are not. As contributor H says, the painter will probably charge more for his end. He will have at least 3 days work there, if he can cover it with one prime coat, and two top coats, depending on color. Keep track of all your hours on this job including planning, design, ordering materials, construction, cleanup, installation, cleanup again, and see how you do. My guess is that will be the last job you do for that price. It's all a learning experience, but if you don't track your time, you will never learn your real costs to be in business.

From the original questioner:

Thanks for the responses. I'm not trying to undercut anyone. In fact, I want to be slightly higher, if anything. I thought it was just a good price to the customer, not a great price, but oh well, live and learn. I will definitely increase my prices from now on. Yes, it is a learning experience. So do you guys price per linear ft or just estimate based on each job?

From contributor J:

I don't mean to sound harsh, but your pricing is ridiculously low. Granted different parts of the country have very different pricing structures, but $2100 for that built-in? I think if you sit down and really add up your expenses and overhead you'll find you probably did that job for free. As posters have already said, this is the type of work that makes it more difficult for the rest of us to charge real prices. And although raising prices is the end goal, you really need to know how to price first.

You need to figure out your overhead to be able to accurately price jobs. That means everything - electricity, rent/mortgage, phones, internet, vehicle, machinery, everything and anything you spend money on to be in business. Doesn't matter if you work out of your garage, basement, or a commercial building, you're still paying for that space, right? Then figure out what you need to make an hour/day to make a decent living. Once you have that number, you need to add in a percentage for profit. You do want to make a profit, right? Now you're ready to estimate the time you'll spend building and installing it. As a previous poster said, this can be tracked on each job so over time you'll get better at estimating. I think if you sit down and do this math you'll come up with the answer you're looking for, which is how much should you charge to do this piece. Because it doesn't matter much how much I would charge - I'm in a very different market than you. My overhead is different and my cost of living is different... See what I'm saying?

Again, I'm not trying to be negative - we all have to start somewhere. But it's better someone tell you now than for you to realize 5 years from now that you haven't grown your business or made any money.

If it helps, though, I would have charged about $2100 for just the install. I would have used different materials, also, for paint grade. Poplar on moldings only, soft maple for doors and frames. For ply, either mdo or birch ply - I find Okoume too porous for painting. Without knowing any of the construction details, I would ballpark somewhere around $5-8k for the unit painted. But I, like many others, am still trying to refine my pricing.

From contributor A:

It looks to me like you did the install for free. I would have added about 1500 - 1700 for the install cost for a total of about $3600 - $3825.

By the way, contributor J, where are you that you can charge almost 170/ft for installation? In the SE, we see people doing installs for anywhere from 50/ft (ridiculously low) to $120/ft depending on the market.

I sometimes see folks offering to do a job like this for this price to get the rest of a much larger job (e.g. - $30,000 +) where they do the finishing on higher grade work.

From contributor J:

I'm in the Northeast and I agree with you, $50 lf is ridiculously low. If someone said they could install the last kitchen I did ($21k) for $1000, I wouldn't even talk to them.

If I built a unit similar to what the questioner did, I would not price by the lineal foot. Lineal foot is fine for your average kitchen, but that piece is (or seems to be) what I would consider furniture grade. Good amount of moldings, fluted columns, and baseboard, all needing to be scribed into place between two walls. Of course if it was finish grade, it would be even more expensive.

Like I said before, though, different market, different cost of living. I could probably buy a mansion in the Southeast for the price of a decent sized condo up here.

My next project is going into a 1.7 million dollar condo. Two bedroom, not sure of the square footage, but I'd put a guess at under 2000 sf. That's the cost before the new hardwood floors, 2 new baths top to bottom with all that artsy tile work, and repainting. The built-in I'm doing, paint grade, floor to ceiling, installed, will run about $2100 per lineal foot. And I am pretty middle of the road as far as local pricing - there are certainly others in the area who would charge a lot more.

As far as local kitchen installers, $150 would be about average without any fancy stuff. A good installer with a decent amount of crown, trimwork, etc. would easily be over $200 per lf.

I know for a lot of us it's good to see what others are charging. Gives an idea of what the market is like. But the important thing is knowing what it costs to make your business profitable. There are not many places in the country where we could charge what we do here. But my area has one of the highest costs of living in the country. Also lots of old and new money just waiting to be spent.

My last advice is for the questioner and anyone else who wants to get an idea on pricing around the states. Get a copy of last month's Cabinetmaker magazine. It is the issue where they have cabinetmakers from across the country bid on the same jobs. I find it to be very informative, and it really is amazing at some of the wide differences in pricing.

From the original questioner:

Thanks again - this is great info.

From contributor G:

For tall cabinets/pantries, you can figure about 2.5 times the lineal feet of a base cabinet. This equates to about 31 lineal feet (equivalent) of cabinets with a price of $5,200 at the $170 per lineal foot pricing model. Cut back to $150 per foot and you have $4,650 plus finishing and installation, right in line with what contributors M and J suggested.

I just installed a smallish kitchen for $3,000, and underbid it given the amount of work it took (they weren't my cabinets - the kitchen was up a flight of stairs, walls grossly out of square - 2.5" in 8 feet - and the cabinets were out of square by 1/8".). That's $100 per foot, and I should have charged more.

From contributor E:

I'm also in Atl. You could get 425-600LF for this type of work. It depends on the client and your overhead, but when I do the finish as well, it goes to 750 and up. Been there a few times. When you're done with the project, you'll have a great lesson under the belt.

From contributor R:

Not to pick, but don't use the okume for paint grade. It is very open grain and does not paint well. China birch ply or MDF would be a better choice for about the same price. You could probably get most of the mouldings in a pre-primed pine as well. Treat it like *you* have to paint it.

From contributor S:

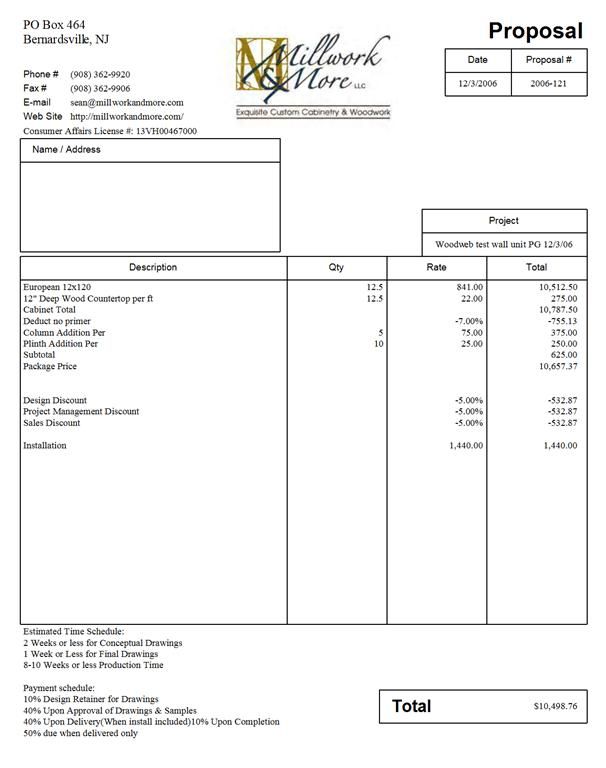

Dang, you guys are cheap. I should close the shop, outsource to you, charge double or triple your costs to me, and go home and roll around in piles of money. Also take this into consideration - the price below is what I would sell it to a designer for. They in turn would upcharge 20-40% on top of this price.

Click here for higher quality, full size image

From contributor E:

Love the discounts. My people see 10k at the top and still 10k at the bottom, and get something caught in their throats.

From contributor I:

I would like to refer the questioner to some of the other threads in this and the Business and Management Forum that deal extensively with estimating methods, and also to a book called "The Business of Woodwork" by Bill Norlin, and to the CMA and True 32 websites where this issue is extensively discussed. What I hope you will come away with is an understanding that if you want to be in business, you need an estimating method that develops your anticipated costs and then allows you to add the amount of overhead and profit needed to make money at what you do. Contributor J's post here describes all this very well. If you depend on lineal foot pricing that is not based on operational estimating methods, you will have the right price for your business about a third of the time - for the rest you will end up with jobs that you can't make money on, or you will miss jobs that you could have gotten, and you will generally not know why in any of these three cases. The problem is that you must want to be in business and know what that means in order for any of this to be meaningful.

From contributor Q:

I'm sorry you have had to learn a tough lesson. I agree with most of the former responses. At the end of the day it doesn't really matter what I could/would/should get for that particular project. What matters is how much it cost you to draw, construct, deliver, and install.

I live in the northeast. I would estimate off the top of my head as 1k material, 1k design/contract/deliver, 1k primed, 5k labor. Total of my cost would be 8k+. Sell it for 10k.

The drawings are very good. I would charge the customer $400 just for the drawings. Did you do the drawings? Have you built this project? Are you taking an architect/designer's drawing (having absolutely no idea what the project costs) and asking us to throw numbers at you in an attempt to come in at a ballpark price?

From the original questioner:

Again, I will say that in the future my price will go up. On this project I provided the drawing from Sketchup. It took about 4 hours to complete, which provides me a cut list and a detailed drawing of each piece to cut. I figure working alone 3 days shop time (9am-4pm) and two days to install. This is no fine furniture project. Just some boxes with applied moldings... no paint, no primer. Oh, and my cost was less than $500.00.

From contributor T:

$4256.00 installed unfinished. Previous customer, or would not even bid.

From contributor L:

So what was the total contract price? I see a lot of other guys saying what they would actually charge except for you. What was the final total amount that you charged? And how much time did it actually take you to build/install? Did you make out okay?

From contributor B:

I charge $400/ft finished for similar units in So Cal. I would add a couple hundred for the fluted columns in the middle (I normally use them on the ends). I would charge extra for pulling the center cabs out as well. I have a maple unit that I built for my home (maple veneer core ply, maple face frames and raised panel doors, one with glass). I spent a little over $1100 in materials, including finishing supplies. I think you have about a 2-day job to build and about 8 man hours install time. Figure your real costs, add in your labor, overhead, profit, and there is your price. In my market, you gave that project away.

From contributor V:

A word of caution to many out there regarding "paint grade." I found out the hard way that "paint grade" can be interpreted many different ways. Most of us assume that it means a lower level of finish, however there are some that it means a higher level of finish and so a higher level of prep. This will affect the materials that we use dramatically, as well as the construction methods and filling methods used.

The job we did was finished with a coat of antique white paint that was applied in a spray booth. It showed every single crack, nail dent and sanding flaw. The amount of extra work that went into prepping the surface for the paint was unbelievable. When the dust settled we figured it would have been less expensive by 20-30% to have made the units out of real wood, such as walnut, and a clear coat. Conversely we did a job for a penthouse and the paint was brushed on. We were very well prepared for the finish, having learned our lesson, and the painter said he had never seen a surface that well prepared. The lessons from this were invaluable but costly and we have learned that what some feel will be a fast and cheap finish may not be what the client has in mind. Material and joinery choices will make or break the profit, so choose wisely.

From contributor K:

Don't make the same mistake I just did on this last cabinet job I did. I charged 2800. Not only did I underestimate my time, I also included the design, lacquer finish and install in that. Even here in SW Florida, I could have charged double. Biggest mistake I ever saw coming. I'm not sure what area you live in in Atl, but from my time there (Buckhead 3 years, Dekalb 5 years) I know that it is possible to charge 3x what I did and still be competitive.

Click here for higher quality, full size image

From contributor U:

That's a nice built in. Yeah, I have raised my prices to $35.00 per cubic ft base. That's just bare, straight wood - no extras. Everything else is additional.