Question

I need to make some radius cabinet faces from black walnut. What is the best way of doing this? Steam bending or laminating? When a radius front is made, do you also radius the vertical stiles or leave them straight and just bow the rails?

Forum Responses

(Architectural Woodworking Forum)

From contributor P:

I like to do bent laminations for everything when I can. Sometimes I will cut the door rails from solid stock if it does not require too large of a piece of stock and the grain remains pleasing.

I always put a slight radius on the stiles. This can be simply done with a hand plane or you can do it on a shaper. Things get a bit tricky if you are doing cope and stick or r/p doors, but it's all doable with a bit of thought and patience.

From where I sit you have a few options:

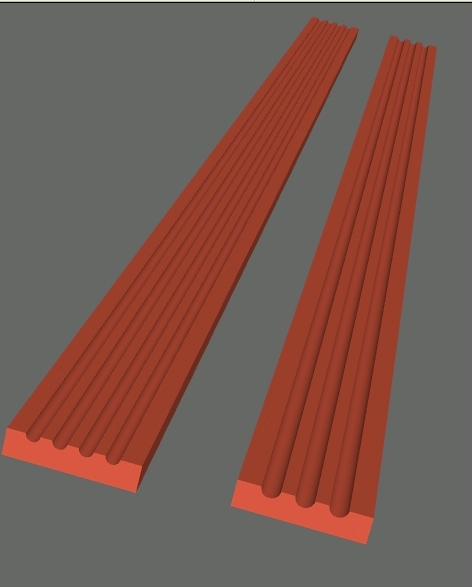

1. Laminate the curve, or bandsaw the rails from wider stock, and leave the stiles straight, (or even put a slight radius on them with a plane as suggested above.) Cooper the panels (like a barrel) and then sand them and shape the panel raise.

2. Veneer MDF parts with a vacuum bag.

3. Make a phone call.

I have used all of these options many times and the results have always been acceptable. The answer to your question is more about the destination and not so much the journey. Are you looking to increase your knowledge and skill or your bank account?

Laminating is pretty easy even if you don't have a vacuum press; you can make a cawl and glue up the strips. As far as the stiles, I would draw a full size section of the door with a top down view. If the radius is wide enough that you can hardly see any variance across the stile when you put a straight edge across the inside points of the stile, you should be fine with flat stock. Make a radius jig for your copes.

If you are doing raised panels, then use a vertical raised panel cutter in a router table with a high fence and some type of guide to keep it tight and perpendicular to the knife. It is not as daunting as it looks and can be quite an enjoyable challenge.