Repairing Table-Top Cracks

Tips on how to patch cracks in a wood table top caused by shrinkage and poor design. October 27, 2008

Question

I recently purchased a number of teak tables from Indonesia that have developed cracks ranging from 1/8" to 1/2" in width. The tables are 8 feet long and the cracks do not run where the boards are joined but at random throughout the planks. The table has a frame surrounding the cracked boards so the boards can't be glued and clamped. Any recommendations on how to fix the tables?

Forum Responses

(Architectural Woodworking Forum)

From contributor L:

Sounds like the typical wet wood import problem. Saw the tops up, dry the wood and start over. Not knowing how the frames are fastened to the top boards I can't say for sure but it sounds like the old stupidity of cross grain gluing. Never has worked, basically can't.

From contributor D:

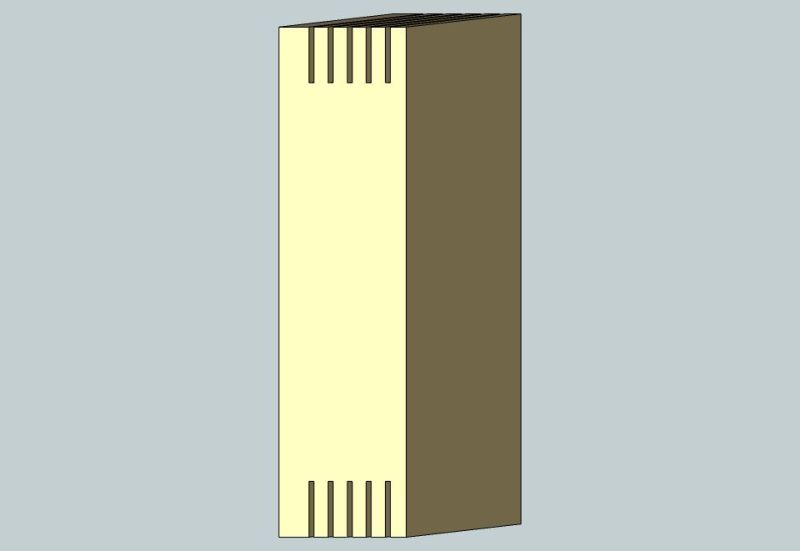

Yes, poor design issues. However, I have repaired dozens of these Indo teak tables for my neighbor. We usually wait one full cycle of the seasons before doing the repairs. Back bevel shims and glue into the cracks. If the crack is a tear, we will cut a freehand slot with a 1/8" router bit. I am writing this on my coffee table which has a 3/4" shim on one edge that was let-in about five years ago. Oh, to finish the shims, we mask off the area and spray dark walnut toned lacquer or brush on some pigmented shellac. These things are not built to flow with the seasons - they will continue to swell and shrink.

From contributor M:

You could always inlay a dovetail key into the crack, fill it with black epoxy and call it a decorative feature.

From contributor R:

You may get away with inserting strips. I have come across this myself. I clean up to the sides of the splits to a depth of 6mm (1/4") and out to the sides about the same. Machine the strips so they sit proud about 1.5mm (1/16"). Once glued in place with PVA, sand to flush.

From Professor Gene Wengert, forum technical advisor:

The high MC wood problem, as stated, is common with imported products, but the low movement of teak makes it rare in teak unless the wood is exceptionally wet and then they would have had a problem gluing it so well that the cracks are in the wood and not the glue joints. My first question would be whether they used another species that looks like teak. Second, without the frame being tightly fastened to the top and assuming that the top is not laminated, you would not have had this problem. The top, as already stated, must be able to move with the seasonal change in MC; slotted screw holes are one solution, but the screws cannot be fastened too tightly or they will not move. Also, try to avoid screws at the edges of the top as that is where the maximum movement will be seen. Finally, if the wood is improperly dried and has some fine cracks in it, when the top dries further in our North America climate, these cracks will reopen. Re-opening of existing cracks and then worsening is more common than forming new cracks... dry wood is so strong that new cracks are hard to form.

As the cracks are now open, it would be good to repair now, as in the summertime, they will close somewhat. Otherwise, wait until January next year (low RH in the house) when they are wide open again.

From contributor O:

On a recent trip to Arizona I saw some tables made with mesquite which had natural splits and cracks in them. They had been filled with black epoxy and they look great. As long as the tables have done their thing and are dried out and there is not a construction problem, this could be an easy fix.