Sawing High-Growth-Stress Wood

Logs will bend in the mill if you don't turn them frequently. February 26, 2005

Question

I'd like to get some input on sawing 5x8x24 ft poplar cants and how best to avoid bending/trim cutting and the resulting waste. The logs are 10-12" in diameter, freshly cut.

Forum Responses

(Sawing and Drying Forum)

From Gene Wengert, forum technical advisor:

Do you mean yellow poplar or aspen poplar? What do you mean by "bending/trim cutting"?

From the original questioner:

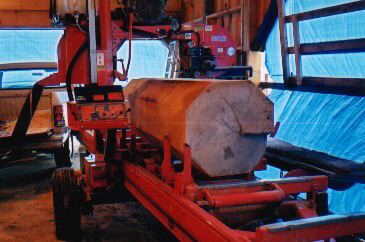

When I start slabbing a tulip poplar log, it immediately bends lengthwise, then I take a trim cut to straighten it, then usually 180 degrees over and do the same. I have a difficult time getting (2) 5x8x24 size cants out of a 12-16" diameter log because of the bending. I don't have a similar problem with white pine, oak or cherry, but hickory acts in a similar way to poplar.

From contributor S:

I just sawed some hickory last week and it did just as you describe. I had cant squared up at what I thought was 12x12. I was aiming for 2 6x6 for a wagon rack and it stressed so bad when I was sawing, it made me nervous. They come off the mill at 7in and 5in and it was 16 ft long.

From Gene Wengert, forum technical advisor:

The problem is caused by growth stresses. Sawing equally from both sides is the cure. Oftentimes these high-growth-stress woods are sawn with two saws at once (twin band, 2-saw Skragg). In most of the world, sawing equal amounts off of both sides to balance the stress immediately works. Oftentimes, with just one saw, the carriage will have knees every 3 feet to help hold the log, but frequent turning is the only cure to keep the stresses balanced.

Once sawn, the stress can cause large end splits, bow and crook.

From the original questioner:

Thanks. Gene, if you saw only from one side and then the opposite, you might as well trim the first side so you have one straight datum side to start with, otherwise you start and end with a thick section and the middle becomes a belly. A center split to get two straight cants at the same time almost becomes impossible with these woods. The double under-over saw makes a lot of sense.

From Gene Wengert, forum technical advisor:

Trimming is the process of cutting lumber to length. I do not understand your comments about trimming.

To keep the stresses balanced with one saw, then you saw one or two pieces from one side and then rotate 180 and saw two or three, rotate 180, etc. With 4/4 you can saw several pieces, but with 8/4 perhaps only one before rotating.

I am not sure what you mean by a double under-over saw. Perhaps you mean saws that are horizontal rather than vertical? It will not matter if you use a twin saw that is vertical or horizontal.

From the original questioner:

Gene, thanks for raising these questions. Trim cut I call a saw cut after I discover the log has been bowed. I take a cut about 1/2" deep or whatever it takes to take the distortion out, then I can turn the log over and it rests on a flat surface. It is more work, but I had good luck with it. Cut a log yesterday and it worked out fine. I had no distortion after taking these small "trim" cuts. I'm aware of the ganged reciprocating vertical saws. Don't know if they make any horizontal. I might have misunderstood you there.

From the original questioner:

My terminology was off about the trim cut. It should be "skim" cut, since I'm skimming the surface to remove highs and lows from the previous cut.

From Gene Wengert, forum technical advisor:

Skimming makes more sense, but turning the log more frequently will eliminate the need for such cuts.