Question

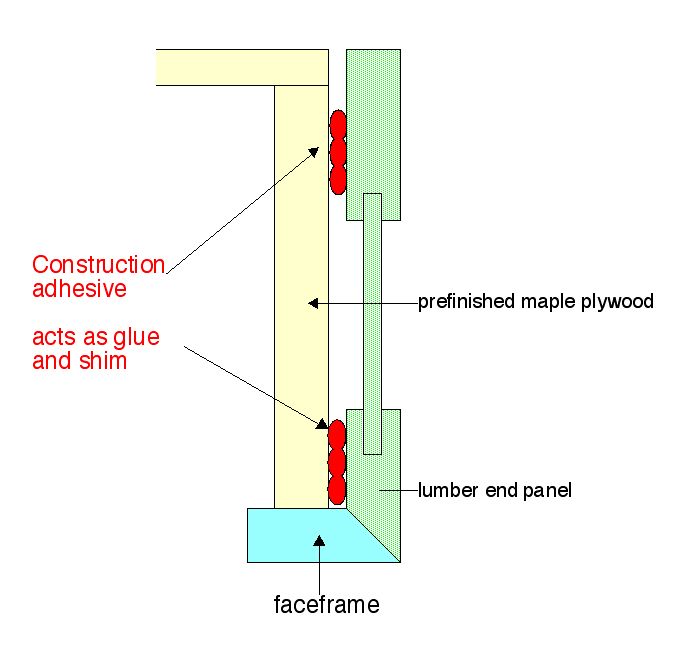

I am trying to solve a production problem and I am hoping someone can help me. We regularly apply mitered end panels to pre-finished maple plywood. For a variety of reasons there is variation in distance that the miter extends past the pre-finished plywood.

We typically measure this discrepancy and stick a wood shim between the pre-finish material and the end panel. It sometimes takes a few tries to get the shim correct thickness.

We would like to put a more flexible shim in this location, something like a butyl caulk that could span the distance and provide some adhesion. The caulk would have to bond with the pre-finished surface as well as the paint grade surface.

Can anyone suggest an adhesive that might do this? I would like something that is relatively low odor, quick dry, and easy to clean. Does anyone have any idea?

Forum Responses

(Cabinetmaking Forum)

From contributor F:

Use finished one side ply and silicone.