Slider, Panel Saw, or Festool?

"All three" is the easy answer; but here are some thoughts for the cabinetmaker who is forced to choose. April 29, 2012

Question

We are a small shop that builds Kiosk and POS displays. Lately we have been working with some panel stock up to 4x10 and will not have the long term need for a sliding table saw. I am considering a wall mounted panel saw or the Festool plunge saw with guides. Does anyone have an opinion on either of these choices? I am obviously looking for both accuracy and speed. Space is not an issue.

Forum Responses

(Cabinetmaking Forum)

From contributor M:

Festool is accurate and can give a good cut, but it is not fast. By the time you set the thing up for the first cut you would be half way finished processing a panel on a slider. There is some debate on vertical vs. horizontal saws. In my experience horizontal is a lot faster, but not all seem to agree. I would say everyone would agree that a slider is a lot more versatile. If space is not an issue and you have the budget for either, get a slider.

From contributor L:

I've never seen a wall mounted panel saw that did a really good job, they may exist but most are relatively crude contraptions that use a skill saw on some tube guides. The Festool makes an accurate cut but is slow. If you need a good cut on both sides of the board, reasonable speed and true square, and angle and bevel cuts, a slider is the best bet. Vertical panel saws are great for rectangular cutting but have limited angle cutting and most can't bevel cut. We are also a small shop doing only commercial work including kiosks . Even though we now have a beam saw and router the slider is still used for lot of odd cuts and holding cutting jigs.

From contributor P:

I've used both. A Striebig vertical panel saw is dead accurate, within a few thousandths (or less) over the length of the saw. We also had an Ulmia slider, albeit with only a stroke of 50", and a Festool saw. The Striebig was fast and could run through piles of panels in no time, as long as the cuts were 90 degrees. The Ulmia was used for solid stock, small stuff, bevels, dadoes, jigs, tenons, rips, etc. The Festool was used for the unusual - the occasional angled cut, or long cut beyond the crosscut or rip capacity of the other saws, or a long bevel, or plunge cut into an already constructed piece. It was the only way to do it and do it well, in many cases. If you only had a stationary table saw and the temporary need to buck down a stack of 4x8's before running them through the table saw, a Festool is a good way to go, but if you are thinking of doing ply on a steady basis, you will eventually want a faster way to do it. A vertical panel saw is a great way to do that, as long as you get a good one. You will always want a good, solid, accurate table saw to go along with that, to do everything it can't. A 9' plus slider may be able to accomplish both, if it can do the simple tasks of a standard table saw along with the panel work.

From contributor T:

The Festool will do the job. It's as accurate as your tape measure, eyeballs, and the sharpness of your pencil. A single long guide is better than two smaller ones joined together. I throw sheets on a sawhorse with four sacrificial 2x4ís under the sheet and cut away. Cut quality is very good.

From contributor U:

The Festool will do a much better job than a cheap vertical saw. It will still be useful for on-site or odd jobs if you do grow into a nice panel saw on down the road.

From contributor Y:

I'm in the same boat currently myself, with some space limitations. I'm leaning towards the Festool with an idea of possibly building a permanent jig with the track for true 90 degree cuts as that's what I will be using it for most of the time. Someday, if space permits, I'd love a slider, but it won't work now.

From contributor N:

I would say both. We have a Striebig vertical panel saw and it takes very little room. It will cut up a whole kitchen in no time at all and we use the Festool for any compound angles. We have made jigs that sit on the saw for 22.5 and 45 degree angles. The Festool really shines when installing pre-finished wall panels, etc. Straight lining ten foot boards is also easy using the panel saw.

The comments below were added after this Forum discussion was archived as a Knowledge Base article (add your comment).

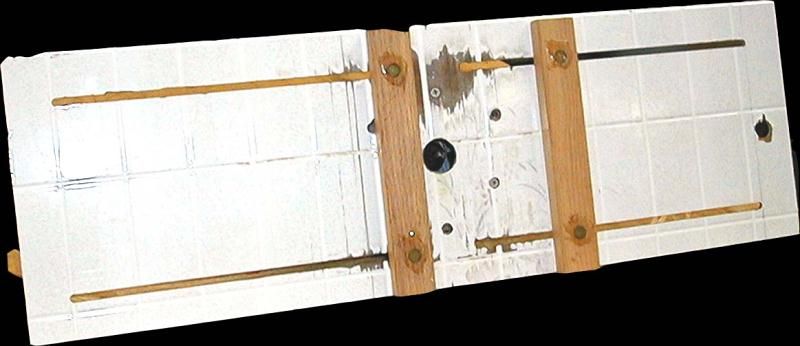

Comment from contributor D:

I use a simple jig based on the Festool system. I take scrap 3/4 sheets goods approximately 12" x 96, 50, and a third piece 30" in length. Take a good quality circular saw (I'm still using my 1985 Black and Decker Super Saw Cat) and ensure itís set to square. Measure from the blade to the far side of the base, most are about 5-1/2". Measure from one edge of the 3/4" plywood about 6" on either end, snap a light line, and attach a straight edge out of scrap 5/8" x 2" lumber. Set this on your saw horses, set the blade depth to 7/8"-1", and slide the saw down the length of the straight edge. Do that on all three separate jigs, the 96", 50" and the 30". Like the Festool it is as accurate as your pencil is sharp and I always use a stick rule. I also always use #3 pencils and a battery operated pencil sharpener. Hypodermic points on the pencils always ensure tight work. Measure up on both sides of your sheet, place the edge of the jig on your pencil mark, clamp, drop the saw, and go. Lengthwise cuts require no saw cross 2x4's, but crosscuts will.