Question (WOODWEB Member) :

I bought a used SSC ES5 (the original 2002 model, euro-style) a few months ago, and upon first using it, found it to be cutting satisfactorily. I used some import birch, though, and that stuff releases stress just thinking about cutting it. While I squared a full sheet just fine it seemed, I wasn't fully convinced. It wasn't a big deal at the time. I'm afraid that doesn't make much sense now. The sheet was either square or it wasn't, right? Fast forward to a real job to use the new-to-me saw (using domestic 3/4" birch, Columbia purebond), and now I don't have a square sheet.

Here's what I have done with the saw and frame: put into place, checked for level and ripped new surfaces on both the lower shelf and flip-down small parts shelf. I have not done anything with the leveling feet of the frame as it seemed to be sitting just fine without any adjustment there. As I already mentioned my test sheet fell within tolerances a few months ago.

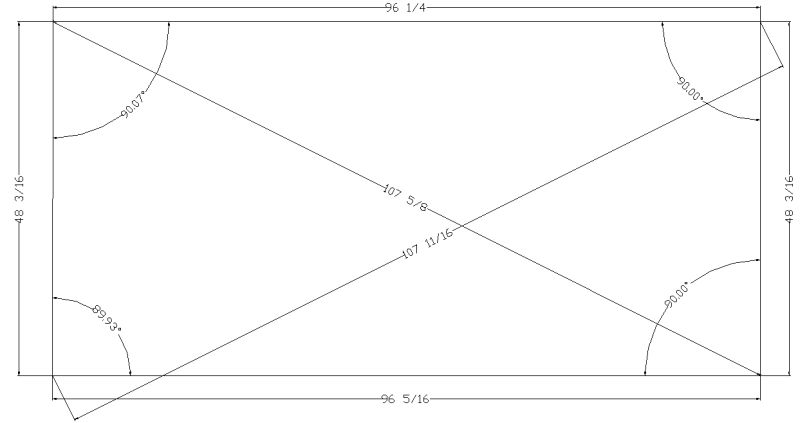

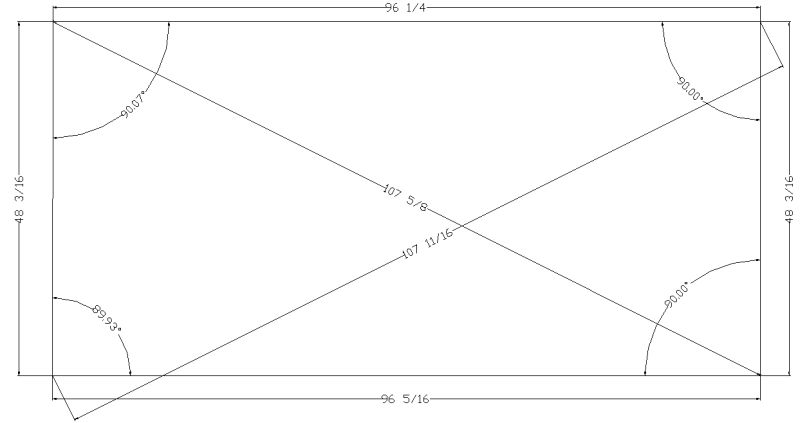

Today's sheet yielded the following measurements: Top left is >90 degrees. Distance across top is 96-1/4" or 2444.5 mm. Left end crosscut at position 3.

Bottom left is Sheet is parallel top to bottom and measures 48-3/16". Diagonal top left to bottom right is 2733.75 mm, or 107-5/8" plus a tiny bit. Diagonal bottom left to top right is 2734.75 mm or 107-21/32". The right end corners are square for practical purposes (18" blade in combination square). The right end was cross cut at position #1. The left end was cross cut at position #3.

I've not made any cross cuts with the saw at position #4, and position #2 is the center crosscut position of the saw frame, and the location for cross cuts when using the flip-down shelf. At position #2 with smaller parts, regardless of the shelf used, I got similar results top to bottom as I am showing here.

I don't think 1/16" difference over 4' is acceptable. I mean, it never has been, right? So before I go semi-blindly into this, I wanted to get your thoughts. Given I do get a square cut at position #1, I don't want to set about to fine adjusting the set screws on the traveler/carriage. Then it doesn't cut square as I move the carriage to either of the positions to the left. I don't know - could the frame be twisted a bit (perhaps remedied by adjusting the frame feet)? Would that throw it off? The carriage glides smoothly left and right, and it locks positively in both the top and bottom detents at each cross cut position. The manual doesn't say much. In it, it appears that if the machine is level and both detents line up and lock, then I'm good to go.

Below are a couple of drawings to assist with my mess of words here. The sheet diagonals vary a bit from what I measured, but the drawing is ideal, and the real world is not, of course. Thank you for your input.

Forum Responses

(Cabinetmaking Forum)

From the original questioner:

Any movement and also over time, the saw carriage will need to be squared back up. You will spend some money to have a tech do it over yourself. If you watch, you can learn how it is accomplished but is usually takes 2-3 times before you get it.

I pulled diagonal strings from the corners crossing in the middle with 3/4" blocks at each corner holding the string off the back grid. Using the adjustment on the feet I tweaked and twisted until the strings just began to touch where they crossed. Once the frame is straight and square and the back grid is flat you can rip the support shelves parallel to the beam then start adjusting the carriage to get a perpendicular cut to the support shelf using the five cut method. You will probably have to loosen the bottom locking points until you are getting a square cut. Once squared you can move the saw to each position and lock it down on the top and adjust the bottom lock points to match.

I'm no machinery tech but thatís how I did it. If it cuts square at some positions and not at others the beam must not be straight or the bottom locking points need adjusted seems to me.