Staining Glue Lines

Oops! Glue-laminated Alder posts showed tell-tale lines where the glue wouldn't take stain. Suggestions in this thread provide the solution. November 13, 2005

Question

I've made 2 curio cabinets with four 76" posts, one on each corner. The posts are Alder, tapered from 4Ē x 4Ē to 2-1/2" x 2-1/2". They were glue laminated from 1-1/2" stock and planed to size.

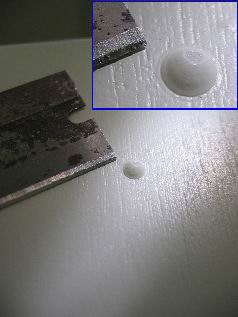

I used the wrong glue. I used Titebond II, which is fine for strength but I didn't think about the finishing. The taper of the posts slices right through the glue layers leaving a glue witness line. The real issue is that on samples so far, the stain which is a dark walnut/cherry/mahogany color, doesn't penetrate the glue line and it leaves an unfinished line across the face of my posts.

Is there anything I can do to get the stain to penetrate? Is there some kind of chemical process or a special stain that will work? I mostly use SW or General stain and finishes. I'm thinking that sealing them first will at least allow me to even out the color, but I'm concerned I won't be able to get the color as dark as the customer wants it if I do. Any thoughts?

Forum Responses

(Finishing Forum)

From contributor A:

For small areas, I've added dye tints to my topcoat and toned or shaded to hide glue lines and other problems. Some of the grain will get blocked out, but you should be able to hide your glue lines.

From contributor B:

I don't know what your design is, but if the client is willing, how about making the posts black?

From contributor C:

How tight are the witness lines? If they are no wider than the space between the two boards and the glue did not migrate into the pores, there are a few things you can do depending on your skill level.

1. Apply your stain as you would normally and achieve the proper color. With a small artist liner brush, brush the stain into the witness lines. This should give you the proper background color. Next, you could add some penciled in grain lines. This step can also be done with an artist airbrush to speed the process.

2. With a fine dental pick, scratch small shallow lines in the same direction as the grain. Try to keep them roughly the same size as the grain lines in the rest of the wood. Next, apply the stain and wipe as you would normally. Allow the stain to dry. Apply another coat of stain to the witness lines and you should be close. Again, the use of an airbrush will help to adjust the color as needed.

Sometimes even applying the stain twice to the witness lines, without wiping on the second application, can rectify the problem sufficiently.

From contributor D:

I do what contributor C suggests, but first I take a snap-off razor knife and scrape out as much of the glue as I can and replace or cover it with filler that takes stain well.

The glue will always cause a problem so I like to get rid of it.

From contributor E:

To contributor D: What filler are you talking about that takes stain well? I've found that glue w/dust is better than fillers for taking color.

From contributor F:

Iím not sure how into the finishing process you are but this might work for you if youíre using an oil stain as a first step. Get some 180 grit paper and wet sand the stain into the wood. Wet the wood well and start sanding in the direction of the grain. Since youíre not using water as a lubricant, you donít need Wet-Or-Dry paper. Any paper will work.

I do this when I find the cabinetmakers didnít quite remove the glue during the assembly stage. Experiment with various grits of paper and Iím sure youíll find one that will work for you. This step works just as well in removing scratches that you discover when you begin staining. In that case I use a block under my paper.

From the original questioner:

To contributor F: I'm going to try your suggestion. It strikes me as the one with the best chance for success and uniformity across the pieces.

From the original questioner:

I said I'd post a follow-up and here it is. I used contributor Fís suggestion of sanding the stain into the glue and it worked very well. Here are a couple of hints I figured out along the way:

1) I worked backwards through grits of paper, starting with 220 then 180, 150 and ending up on 120. Starting with 220 helped blend in the edges of the glue line with the surrounding wood without stripping the surrounding wood of the original stain coat. I applied the last coats with the bigger grit papers very lightly, just scratching the surface. The different sized artificial grain lines I was creating with the papers made a more natural look. It's too much work for an inside corner glue blob, but these posts were the face of the units and worth every minute.

2) Using straight stain didn't always produce enough penetration into the artificial grain lines, so I'd use the sludge from the bottom of the can to create a concentrated slurry of stain and pigment. That worked out really well, but you have to be careful about not oversaturating the surrounding wood with pigment. It will look muddy if you do, but a tooth brush with mineral spirits takes care of it. They came out beautiful if I do say so myself, with much of the credit going to contributor F for his suggestion.