Steel Support for an Overhanging Granite Countertop

Advice on the use of structural steel to support a stone counter, without overkill or excessive weight (and cost). April 9, 2008

Question

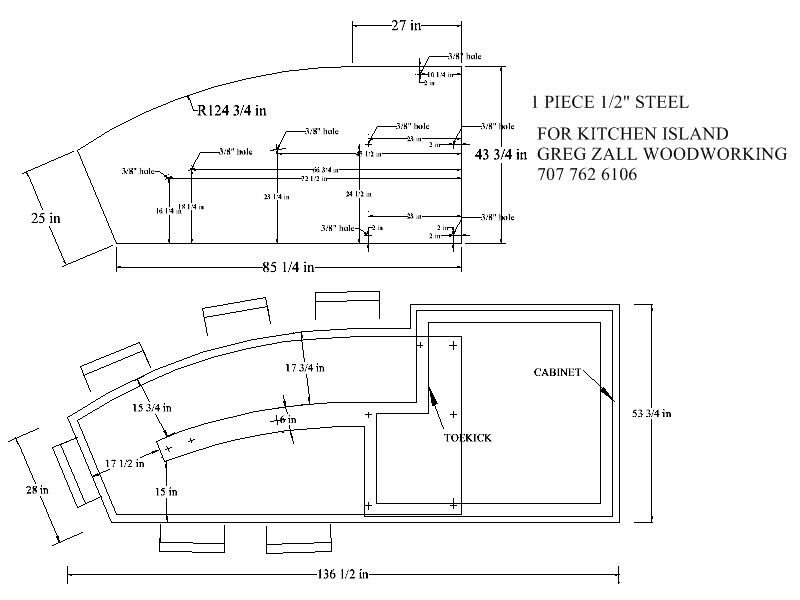

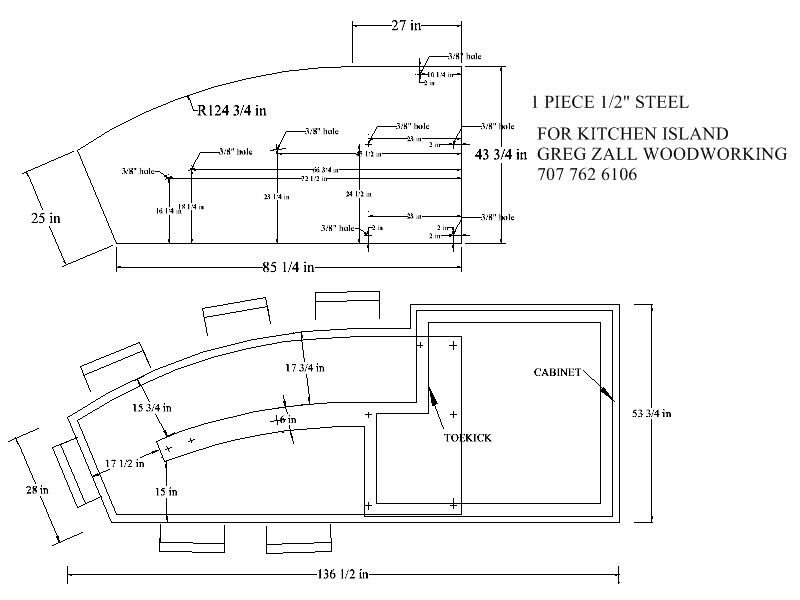

Has anybody out there dealt with this problem? I have an island countertop that extends out over a 6" pony wall. It makes a table with chairs on 3 sides. I want to support the 16" overhang of granite. The countertop guy said to use 1/2" steel that is screwed to the 6" pony wall and extends back to screw to the top of the island. It will sit under the lip of the granite so there is no apron showing.

The problem is this ends up being like 400 pounds of steel. It seems so heavy to even move into place. I have seen countertops with no apron - is this how they are supported? Could I pierce the steel to make it lighter and not lose its rigidity?

Click here for higher quality, full size image

Forum Responses

(Cabinetmaking Forum)

From contributor R:

Why aren't you using wood corbels? Is it a look that doesn't work? You can either build corbels or buy them from your supplier. They attach to the pony wall studs. Another way is to get a couple of turned posts and build a frame under the top supported with the posts. It's all about the look, I am sure.

From contributor P:

I assume you're using 2cm granite since you said there's a lip. Why not use 3 cm and use either steel brackets or wood corbels? 1/2" steel seems a bit much for a substrate. I have seen a top reinforced with steel plating. It was supported by a triangular shaped base and very sturdy. I think I'd try to redesign the base, making it wider than 6", if I were to go this route. I think all that weight on a 6" wide base is a bit much. With the top and the steel, you have to be close to 800-900 pounds.

From contributor K:

Is there room enough in height to build a torsion box 3" - 4" thick to look like a table apron? I just did this in my brother-in-law's house for a 20" overhang behind the island. I did incorporate two custom turned legs, but the field between the legs was built as a torsion box to prevent flexing.

From contributor G:

When the granite guy told you to use 1/2" steel to support the overhang, he probably meant for you to use 3" or 4" wide steel pieces that bolt or screw to the top of the cabinet or support wall. If I were you, I would buy a few pieces that would extend as far as possible across the wall from one side to the other, about 10-12" apart, and one piece straight out the end. You may have to drill and countersink for the fasteners. Silicone the top to the steel and the cabinet, and it isn't going anywhere. From a structural viewpoint, the main concern is probably the fear of some fat drunken retard climbing on the counter and dancing on it, causing the granite to break. That's the trouble with granite - it has grain direction that can make it weak in some areas. Personally, I prefer engineered stone like Cambria or Silestone quartz for countertops. It has no grain and is much stronger than granite, plus it's nonporous.

From contributor E:

I agree that a 1/2" steel plate would be impractical due to the sheer size and weight of the piece. Have you considered a series of 3/4" diameter steel rods let in to the top of the pony wall and radiating outwards, sort of like ribs? We did something similar on an island where the rods were embedded into support structures within the cabinetry. The only thing that shows is the rod if you aren't doing a built-up edge on the granite. You could go to stainless steel if the appearance is critical to the design. The only tricky spot I can see is the overhang at the end - you might need to have something special fabricated for that spot. This all assumes that wood corbels are not acceptable for the design, as the other guys have pointed out.

From contributor G:

For any stone overhang in excess of 12" we use 1/4" steel plate 3" wide that is routed into the subtop and screwed to the pony wall. We space them every 16 to 24 inches and cover the underside of the subtop with a plam backer sheet.

From the original questioner:

Thanks, everyone. Customers do not want a messy, non-clean-looking apron. But I like the corbel idea, maybe with steel L bracket inside my walnut corbel. The steel guy yesterday said it is done all the time with 1/2" steel and that it is manageable to get into the room with 4 guys on it and once in place, is there forever. I think this is the easiest way to go and the responsibility is on the counter guy, since he instructed me to do this, but I am still a bit worried about the whole thing.

From contributor I:

I have used 5/8" aluminum plate for this type of thing. It is much lighter than steel, and not a lot more expensive.

From the original questioner:

Is the aluminum as rigid as steel? Also, the steel is costing me $700.00. I am not sure I want to pay more. I love the idea of just insetting 1/4" X 3" bar steel into the subtop - that is for sure the easiest and lightest solution, but it seems like it would flex. I would need to do a mockup. Anyone else think it is worth the time to try this solution?

From contributor G:

We have been using the 1/4" x 3" steel plate routed into the subtop for 20 years with no call backs. A full 1/2" steel plate subtop is way overkill unless he's field dressing a pachyderm on the island. Is the countertop guy new to the industry? If he is insisting on this type of support, the cost should be split!

From the original questioner:

Thanks for the testimonial. That is exactly what I needed to hear. Another contractor has suggested 1/4" steel plate with 1/2" plywood on top bonded with Gorilla Glue. This seems really manageable. I am waiting for the countertop guy to give approval.

From contributor O:

An analysis of your stress points suggests that you could reduce the size and weight of your 1/2" steel plate by 15 to 20%. Basically, you could cut the steel plate in a line starting from the lower left corner of the cabinet to the upper left corner (in the diagram). Most of the steel extending over the top of the cabinet is redundant.