Straightening Frameless Cabinet Sides

Dealing with bowed plywood that causes drawers to jam in a frameless cabinet. November 7, 2007

Question

I've always built face frame cabinets, but my last projects requested frameless. On both jobs I had an issue where one drawer bank box bowed slightly on an exposed side, causing resistance on the center drawer slides. I typically only brace/block top and bottom on drawer banks. On both occasions the sides were 3/4" maple plywood. I know some of this could be eliminated by using MDF core, but if possible I like to use the ply so I can screw my slides directly to the box. I ended up putting a brace in between drawers to straighten, but am curious how others with more experience in frameless prevent this or fix it.

Forum Responses

(Cabinetmaking Forum)

From contributor A:

You've got to have flat material for frameless cabinets. Plywood will bow, so if the next cabinet bolted to it won't straighten it out, or if the applied end panel won't straighten it out, then replace the cabinet side causing the trouble. Get a line borer and use the fat 5 mm screws - stronger than a small screw, and the slides are always in the right spot. Going with system holes saves a lot of time on a job.

From contributor J:

You probably don't want to use melamine because most face frame guys consider it junk, but it won't have nearly the problems that plywood will have. Switch to melamine for frameless and use 5mm euro screws.

From contributor H:

Replacing the side panel is overkill. Adding a 3/4"stretcher between the drawers is the best way to deal with your problem after the fact. We all have to deal with imperfect materials occasionally and if the client will never see the quick fix, then do what you need in order to keep making money.

From contributor C:

Occasionally when you get a bad batch of plywood that is not flat, the foreman should make the call early in production to add at least one more stretcher between drawers. It's a pain, but easy to remedy as soon as it's noticed. (Use a better grade of ply next time.)

From contributor P:

Stretchers between every drawer. Make it your standard detail. Takes way longer to deal with fixing one bad box than making them all this way in the first place.

From the original questioner:

Thanks for the feedback everyone. I'm thinking contributor P hit the nail on the head, because it's definitely a pain to make field modifications. Do you think a full depth biscuited or dadoed stretcher is necessary, or would a partial with some glue and pin nails remedy the problem?

From contributor M:

3" wide pocket screws and glue.

From contributor Z:

Contributor P, that is the way I do it also. Stretchers every drawer. I pocket screw them - keep screws underneath and never seen.

From contributor P:

What contributor J said. Flip the cabinet on its head, use spacers off the top stretcher, pocket screw, and you're done. We keep a number of standard spacer combinations for typical drawer configurations and it goes really fast and dead accurate!

From contributor T:

Hard to believe anyone would actually request frameless.

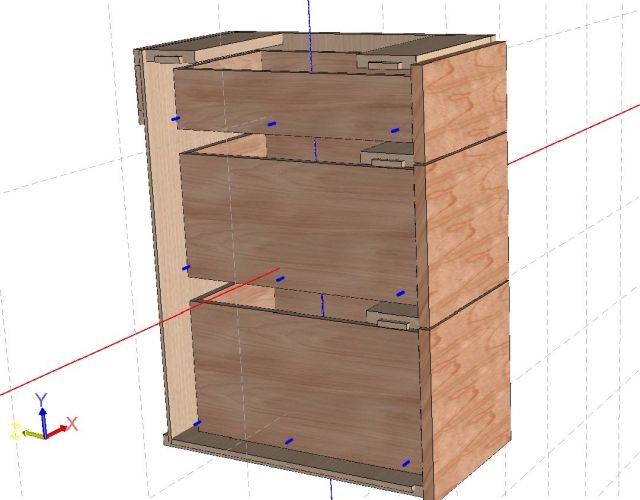

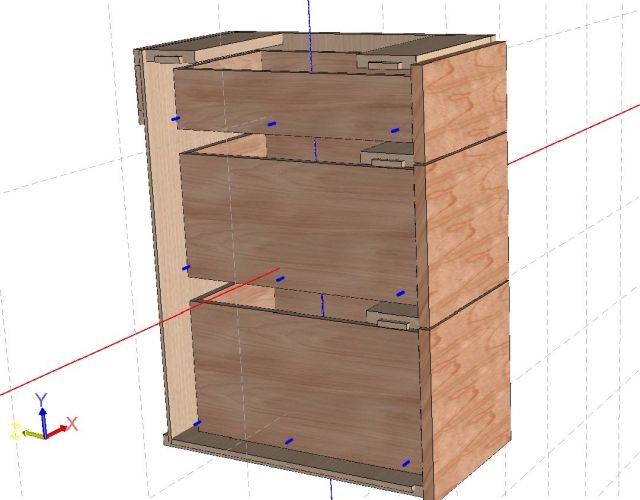

From contributor G:

Side removed for clarity. Use PB core melamine, stretchers thus, and system screws. Bulletproof.

Click here for higher quality, full size image

From the original questioner:

Thanks, contributor G.

Yeah, contributor T, a lot of designers are requesting frameless out here for that "contemporary" look. Gotta conform to what the market wants.

From contributor T:

I'm stuck in the 60's. It's just the very idea... melamine, particleboard, boxes screwed together, etc. Just can't get into it. Still like Dylan and Neil Young, too. Dang.

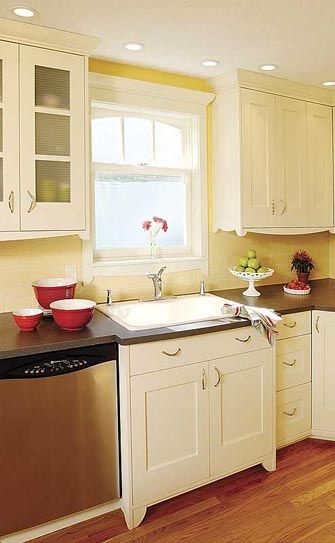

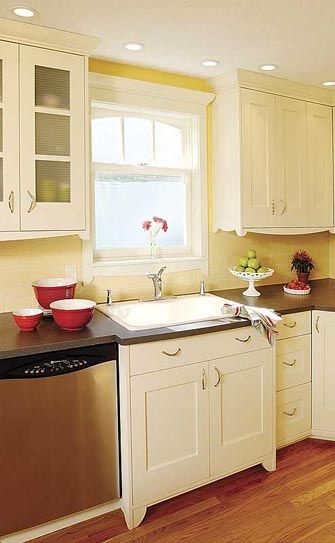

From cotnributor G:

Here's a nice frameless job. As Miles Davis said, when asked why he smoked so much weed, "Wuz wrong wid dat?" No melamine here. Show us the beauty of one of your face framed jobs.

Click here for higher quality, full size image

From contributor T:

Nice. I have given frameless a try both with melamine and with plywood. Melamine, I just don't like - on principle, and because it's heavy and chips easily when cutting. Plywood, as another cabinetmaker pointed out, is never flat and causes fit problems with drawers. So I stick pretty much to face frame with inset doors. I don't need or want a lot of work and there is a small, niche market for this type of cabinetry. I enjoy cabinetmaking, and chucking around melamine would kill the joy for me, I'm afraid.

From contributor J:

It's funny that you say that, because if I had to use plywood and build face frame cabinets, I think it would take all the fun out of it for me. I guess it is just what material and system you are use to that determine what you think is best.

From contributor T:

Here's a pair of cabinets I did a while back. I just finished the matching kitchen, but don't have any pictures yet.

Click here for higher quality, full size image

From contributor U:

I started out twenty six years ago building face frame cabinets, but switched over ten years ago to frameless, and won't go back.

Some caveats:

Panels have to be dead square.

Dimensions must be within 1/32" to look right.

Advantages to frameless in my opinion:

Hardware installed on side panels before the cabinet is assembled... Nothing could be easier than to install a hinge plate or drawer glide to a side panel when it sits flat on your work bench.

No face frame to build, and that represents a huge time/material saving.

I don't bring up the subject of face frame versus frameless construction to a client anymore. I just show them photos or actual projects done in the frameless style, and the subject never comes up.

Granted, you need a good slider or router, edgebander, and line boring machine, but when you have those, building a cabinet is simple and fast.