To Nest or not to Nest?

A spirited discussion on which is more productive: nest-cutting parts with a CNC router, or using a beam saw and point-to-point machining center. June 30, 2005

Question

I have a medium sized architectural cabinet shop manufacturing mostly larger institutional projects mixed with some small jobs. I currently use the beam saw, then edgebander, then point to point machining centre. Is nest based manufacturing faster for my types of projects?

Forum Responses

(CNC Forum)

From contributor B:

If your larger institutional jobs allow you to stack cut on the beam saw, you would have to study nesting closely to prove it faster than your current method. If you rarely stack cut, then nesting would probably be more efficient, especially when you eliminate the material handling between the saw and CNC.

A good compromise is a nested base CNC that can run single parts in pendulum like a conventional P2P. Nest the small jobs on the router and stack cut the big jobs at the saw and run the parts on the router as a P2P. Just make sure the router can actually pendulum process so you don't lose the load/unload time.

From contributor M:

Some other things to consider....

1. If you nest you will not be able to edge bore on the machine (assuming you do now).

2. Depending on the common depths of your cabinets (ends) you might lose a significant amount in yield because you will be using a kerf (router bit) much wider than your saw blades.

3. Any router cuts on your point to point that cut through banding now will require a different process later.

From contributor T:

I agree with contributor B's comments. Either solution is very good... with one being slightly better than the other depending upon your special production circumstance. In the past, I have used a fairly high speed beam saw with a ptp. I kept the beam saw, which I use regularly, however when I upgraded my ptp, I chose to get a CNC router, which was slightly more expensive than the ptp with a slightly greater learning curve. I can use the router as a ptp if needed or I can nest, which I usually do. I have never taken on any job that the router did not perform in an excellent way. My operation is 21,000 sq feet but my staff is small.

I do not think that the cell vs. nesting debate can be addressed completely in this forum. What has worked well for me may work poorly for another company. Try to talk to machinery suppliers who you trust and who have both options, thereby reducing their tendency to bias.

From contributor E:

I spent about 8 months asking this same question. We were manufacturing with a slider and various boring machines. When confronted with aging equipment and a desire to increase capacity, we chose a nested based router. I won't say it is faster than a beam and ptp, but it was only one machine we had to purchase versus two along with material handling issues and floor space concerns. I agree that if you can stack cut the beam saw, this will blow away any other method, but unless you're stocking box parts, this is hard to do on a regular basis. One theory I heard from manufacturers that sold both systems was 40 sheets per day. If you are cutting 40 sheets or less, nested based will be faster. 40 plus, beam and ptp.

From contributor R:

CNC routers and nested based manufacturing have been replacing P2P and beam saws for years now. The biggest problem I see with P2P/saw is that all parts must be handled twice, and issues with accuracy grow with each handling.

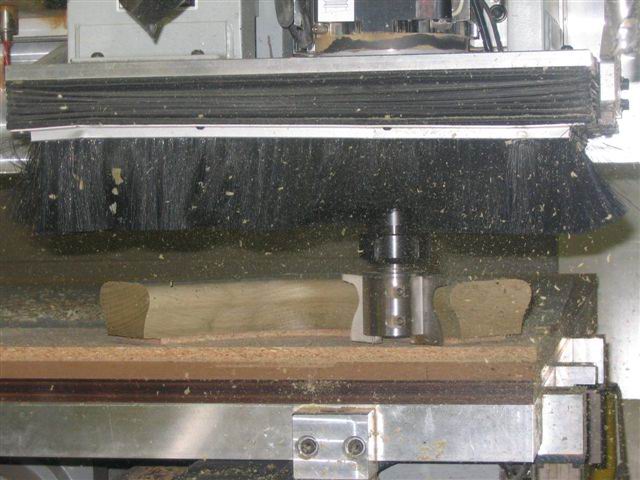

Today's high speed machining centers (we use a Komo and are very happy) blast through material at a staggering pace. The new fast drill code on our machine drills 32m holes every bit as fast as any P2P. Advances in tooling technology allow us to use 3/8 and even 1/4" bits to reduce the loss in kerf compared to a saw blade.

Any time secondary operations are required on parts, the CNC router is best suited for sizing the part and flipping it over to do the back side work. Sizing it on a saw and machining it on another CNC just did not make sense to us.

Our 12ft table allows us to nest 8ft material and have a secondary station for back side parts. This setup works great for us, and we'll never look back.

From contributor D:

More often than not, if you have the room, the best solution is to cut everything but the case shell at the beam and cut the sides and top/bottom nested with blind dados, etc.

Stacking is a good option also, but from what I have seen it not as accurate as I would like. It may just be the few shops that I got parts from not calibrating their machine properly or warping material. That is the nice part of the nesting, as you have pretty much exactly the same size parts of each case and the blind dados can adjust for material thickness differences to give you a true finished size box.