Tool Speeds and Fire

Thoughts on how to prevent the tool overheating that could set your material (and your shop) on fire. October 15, 2009

Question

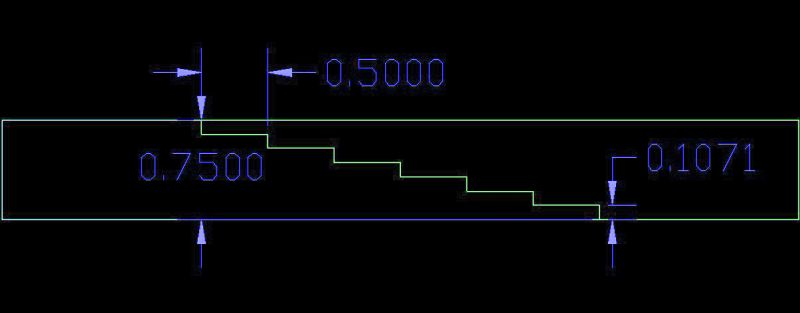

Today I was routing out some wood slots for a project. I was using a 1/4" end mill cutting through 1/4" wood. I was running my feed at 250 in/min. However the wood was chipping so I slowed it down to 75% and upped the RPM from 18000 to 18600. I know that's not a big jump but the wood was cutting a lot better. When I was about half way done cutting these slots I had a small burn hole on one edge which grew and turned into a small burning fire. I put it out and cleaned it all up. Can anyone tell me what caused this? Is it the bit getting too hot? Or is the speed that I am running this too slow?

Forum Responses

(CNC Forum)

From contributor E:

Chip loading is a big part of the equation. RPM, feed speed, and tool diameter. How many flutes on the tool? Two flutes at 18000 rpm should be feeding about 375 ipm. Is the tool stopping in the material? That could also cause burning? Is the tool sharp? There is a lot to consider. I'm sure I've missed some other possible causes.

From contributor G:

I have said this before about any material that you are cutting - keep it cool. Doesnít matter what type of tool and doesnít matter what type of material no matter what anyone says. Too much friction will cause a fire no matter what you do.

From contributor L:

As said above there are a lot of things to consider, but I'd be running at a lot slower RPM at that feed rate - maybe 13000 at the top end and better at 10000 or below. If youíre not up on chip load you can go to the Onsrud sight and they have a lot on info on chip load and how to figure it. They also talk a little about using different bits. You should almost always be able to reach in and touch the cutter after cutting a file and the bit should be at just above room temp. If you canít hold on to it comfortably, you have the wrong feed/rpm settings.

From contributor D:

Most end mills are not designed to plunge, and can only ramp in. You can tell by the grind at the tip of the tool - it needs to be all the way across the width of the tool to be able to plunge.

From contributor G:

As contributor D mentioned most tools do not have the bottom relief to plunge. We manufacture all tools with a plunge design, but I do recommend ramping as this will provide longer tool life. Use an up-shear tool and if your parts are small, use a slow helix upshear.

From contributor B:

Wood and paper start to burn at 451 deg. F. Your tool should not get any hotter than 300 deg. F. Faster feed will cool the tool higher RPM and light chip load will make it run hotter. Use a temp gun to check the temp of the tool when it comes out of the cut. If you are using a dust collection system then the fire will go there.