Tung Oil Finish Differences

A discussion of the various finish types containing Tung oil and their performance differences. February 27, 2013

Question

I am planning to finish some shelves (Sapele) and thought I would try Tung oil. Is there a difference between regular pure Tung oil and polymerized Tung oil? Any thoughts are greatly appreciated.

Forum Responses

(Finishing Forum)

From contributor M:

I've recently researched this same subject as we are building 30 passage doors out of rustic oak for a client that wants to use tung oil for a finish. His oak floors throughout the house have that finish and he loves it after 25 years of use.

I ordered our six gallons plus a gallon of the Citrus Thinner from Milk Paints. You really do need to thin down the initial coats as the oil is kind of thick. You want that initial coat to soak into the wood.

From contributor J:

I would test the product first. The last oil finish that I put on my boat Sapele table is still weeping out a year later.

From contributor R:

Contributor J has a point. Tung oil takes quite a while to auto-oxidize/crosslink. You might try a thinned oil to bring out desirable features in the wood, let it dry, then coat with a couple of coats of Tung oil based varnish. I use a Tung oil/phenolic resin varnish from US Polymers, but Epifanes makes a serviceable one for marine appls. It hardens quite nicely and can be rubbed after curing.

From contributor W:

They are not the same. Tung old polymerzes after it is applied and the process takes some time. Polymerized or pre-polymerized tung oil is polymerized by heating it to 300 plus degrees in an oxygen free environment. It is already polymerized when it is applied and thus dries very quickly. Although it isn't recommended for very large projects I've used it on some medium sized ones with good results. It is a common finish for wood gun stocks and smaller quantities can be obtained from a good gun shop if you want to experiment.

From contributor Z:

I have used the pure tung oil with the citrus thinner. To really do it right it takes about two weeks. Some people don't care for the aroma of pure tung oil. You can get roughly the same results with Danish Oil, and it is much easier to apply.

From the original questioner:

I get the feeling I may not have enough time to coat/let dry/recoat, etc. I am also concerned with the bleeding issue or absorption of the oil into the wood.

From contributor Y:

The companies that sell finishes are often inclined to be very positive about their products and may not point out its weakness and sometimes even over-state its strengths. I don't have any particular brand or product in mind when I make that statement, but after learning about the actual properties, strengths and weaknesses of finishes, I realized we can't always rely on the manufacturer or sales rep to tell us what we need to know.

Let's start with a little intro into finishes:

Drying oils (linseed oil and tung oil) have poor durability properties.

Oil base varnish is a lot more durable.

Oil base polyurethane is even more durable.

From contributor M:

To the original questioner: Just to clarify - we are not doing the finish work, we are merely providing the oil our client requested. His own finisher is applying the tung oil finish. His experience (as stated) is with a 25 year old floor that has a pure tung oil finish that he is completely satisfied with. He has told me that they periodically (spelled every five-six years) reapplied a thinned down coat of the pure tung oil and citrus thinner. He also has a lot of outdoor furniture that has been treated with the same oil, as well as many furniture pieces inside. I have to say I've seen all of these and am quite impressed with the finish I see - it's a satin, well rubbed sheen that looks totally natural. It does not have thickness to it such as a urethane or varnish finish imparts to wood. Personally I've never used it myself - I prefer restricting my finish work to lacquers and catalyzed varnishes. I'm more at home with these.

From contributor J:

All I know is that the oil finish was (and is) absolutely perfect for the interior teak trim but seems to have ruined the sapele table. Every time the sun gets to shining on it through the companionway, I have to get out the paper towels and start wiping it all off again. It has also turned the wood nearly black despite the natural color label.

If that wasn't bad enough, I can't seem to get any kind of a sheen to it (as I've experimented with multiple coats and drying times on other sapele boards). At this point, varnish or urethane would only make matters worse. I don't believe it had anything to do with the particular brand of oil as I have all sorts in the dock box and have tried them separately.

All I wanted was a finish that I could easily restore from time to time with a simple wipe down. Considering the teak, that's exactly what I got. The oiled mahogany however was a big mistake! I swear if my boat were to sink at the dock, it would leave an oil slick across the entire bay just from the table. Find me an expert article on removing the environmental hazard from my cabin.

From contributor O:

Try danish oil (as others have stated), in other words: Watco. I have not used it on Sapele. Again, it takes five or six coats of Watco to get a great finish, with an elapse time of seven days. Wet sand from 400 grit continually until 2000 grit on the finish coat. Wait a week if you want to apply wax over the Watco.

From contributor Y:

I used hand applied finishes, including wipe on oil base finishes for years without understanding their properties or what was really in the can. As my business grew, I had to start using spray finishes to keep up with the work. Over time I mastered a wide range of finishing techniques and learned a great deal about their chemistry.

I did not ask how to apply a wipe-on finish, the Original Questioner asked about the difference between tung oil and polymerized tung oil. There was some discussion about the way tung oil cures, how slowly it dries, and the fact that polymerized tung oil dries faster to form a slightly more durable finish. No one mentioned the fact that tung oil isn't very durable and there are better choices.

So my goal was to steer the Original Questioner to use a more durable finish (like varnish or an oil/varnish blend (danish/teak/antique oil) that dries more quickly. Drying oils like linseed and tung oil are great when you want an "in the wood" look and not much durability.

From contributor Y:

To contributor J: How long has the finish been on the table? Is it the finish that turned dark, or the wood? Does it still bleed if you get the wood hot (sit it in the sun)? Is it tacky/sticky? It sounds like you may have three conditions taking place at the same time;

The wood contains natural oils that interfere with the curing process of the oil finish you applied. This is not unusual with tropical hardwoods. You're getting bleed out from the pores. This is most common in woods with large pores (oak, mahogany, etc.) The oil finish is having a reaction with something in the wood or a cleaning solution to turn it black. Drying oil can turn dark and semi-transparent when exposed to an acid (chromogenic).

If the table is stored in a well lit, well ventilated, dry, warm place, it should cure in no more than 60 days. If it doesn't, you should use a chemical remover to strip the finish and then apply a different finish (non-oil-base). There are alternatives that will produce excellent results. The brand of oil can make a significant difference. Some oil-base finishes form a protective film on the wood and some don't. The film forming finishes are the ones that build up to give you a sheen between matte and gloss.

From the original questioner:

I think I will stay clear of tung oil for now and use Watco Danish oil. Time is a factor and durability is another.

From contributor B:

I used a product called Starbrite teak oil which is labeled as an ultra-refined tung oil formula. I followed the directions through three applications. The sapele soaked it up like a sponge. It's been more than a year now and it's not tacky or sticky but will still leave your hand feeling a bit greasy and can be seen on blotting paper. The environment is marine with constant humidity and dampness. I could try closing up the boat and running a small space heater for a week or so? That ought to dry everything out and maybe the oil as well. As for the color, I'm just not happy with how dark and dull it turned out, especially the end grain. The teak finished with Starbrite is bright, beautiful, and completely dry.

From contributor Y:

I took a look at the Starbrite website and it looks like they offer finishes that are a blend of tung oil (maybe other oils as well) mixed with varnish resins (polymers) with some UV inhibitors added. These oil/varnish blends have a lot of names, but Danish Oil is common.

Oil/varnish blends are particularly susceptible to bleeding (wet oil coming out of the pores when the wood gets hot). The finish goes down into the wood pores, dries at the surface which prevents air from drying the oil that's deeper in the pore, and then when it gets hot the oil expands and comes back to the surface. This should stop after some months because the oil will eventually dry all the way through. It's normal for the end grain of wood to get darker when it's stained or finished with an oil-base finish. The end grain has a lot of pores and will soak up the most finish.

I would not expect the oil finish to improve in any way no matter what you do at this point. It's been too long for it not to dry completely. I think your best option at this point is to start over. You can have the table top refinished by a local shop or do it yourself. To remove the oil finish, use a stripper rated for varnish (it will be strong enough to soften the cross-linked oil) and use maroon Scotchbrite to scrub the finish off after the stripper makes it soft. You'll probably have to sand or trim back the end grain to get the dark color out.

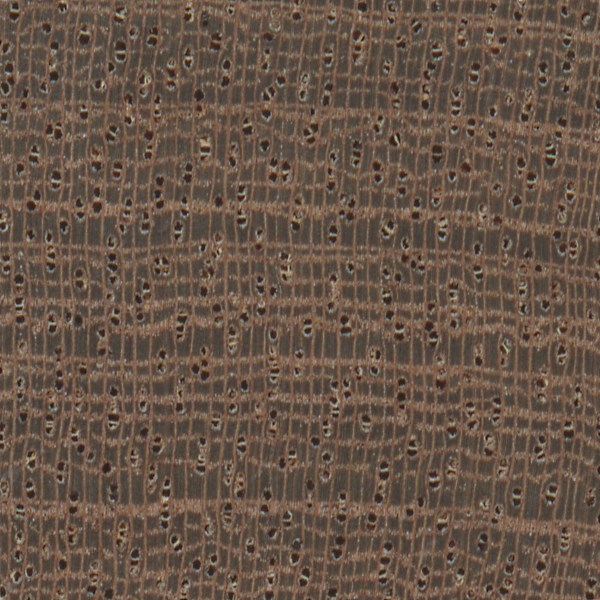

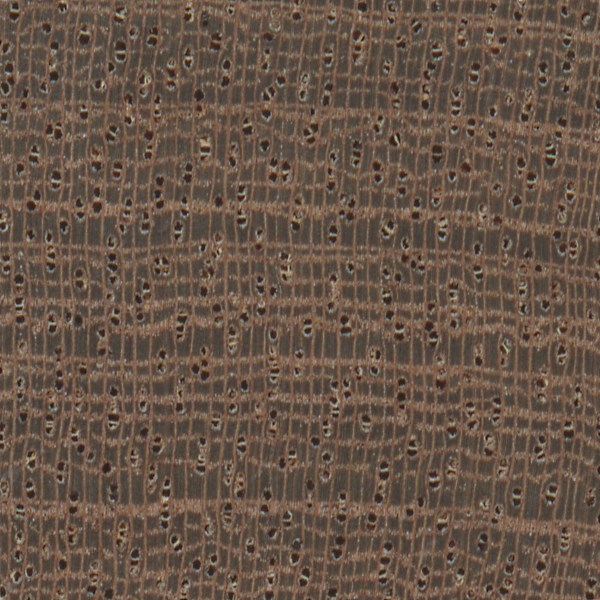

When you remove the old finish, there should not be any dark or shiny spots or streaks left in/on the wood. If there is, you need more stripper and scrubbing. If you decide to go his route, post pictures of your progress on the forum and get input from the folks here to help you get the results you want. Below is a close-up of the end grain of Sapele - the open pores are like straws and soak up a lot of finish.

Click here for higher quality, full size image