Question

I am a millworker and cabinetmaker and I have my first job veneering some butternut on MDF for panels. What I should buy for a vacuum bag system?

Forum Responses

(Veneer Forum)

From contributor A:

Here is what you need to know about vacuum bags and pump.

Specifications and Considerations for selecting the right system vacuum press system:

Standard Layup Bags

A 4 x 8 capacity bag is not physically 4 ft x 8 ft - it is oversized about 9 inches on the width and 18 inches on the length. This allows you to press an actual 4 ft x 8 ft lay up. Standard sizes are 4 x 4, 4 x 8, 4 x 10, 4 x 12, 5 x 10 and 5 x 12. Custom sized bags are available.

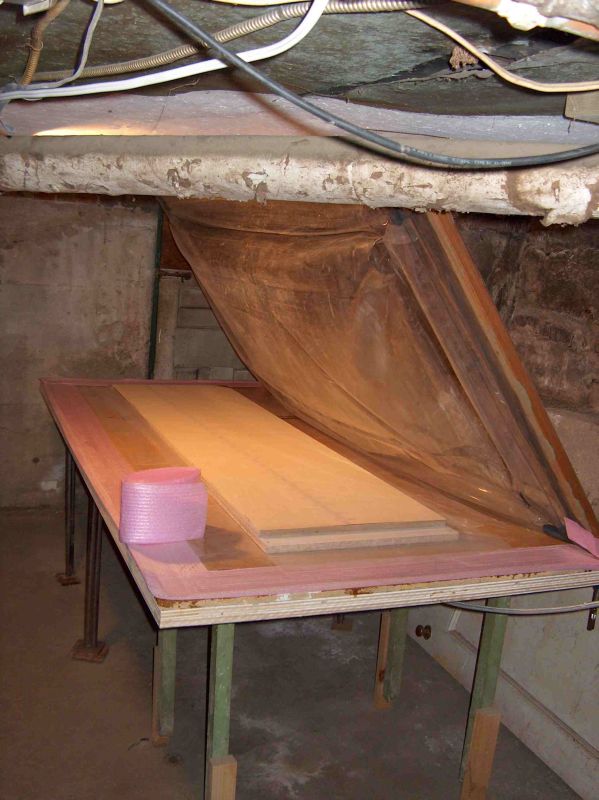

Flip Tops

The flip top offer one person easy access for flat panel and low profile curved work. Loading and unloading is much easier than standard bags. The lay up is placed on the platen, then close the door and turn on the pump.

Laminating Bags

These are used for producing bent laminations (arch window/door tops) and staircase work (long stringers - straight and spiral). Standard sizes available are 8" x 145", 12" x 192" and 20" x 252".

Pumps

1cfm 1cfm, continuous diaphragm pump, operates one bag

5cfm 5cfm, 1/3 hp motor, one extraction point, operates one bag

10cfm 10cfm, ¾ hp motor, two extraction points, operates 1, 2 or 3 bags at the same time

5&10 cfm pumps are oil-less, rotary vane pump with thermal overload protection. See-through filter jar for dust removal. Micro pressure switch maintains consistent pressure, with adjustable setting.