Warp-Free Hardwood Doors

How do you keep large doors flat? Cabinetmakers discuss materials, construction methods, and finishing. July 21, 2005

Question

I am building an office piece for a client, and he wants flat doors with a routered edge. I am concerned with warping on a door that is 24 wide by 26 tall. I originally planned to just glue up panels, but this one door has me worried that it will warp. Does anyone have any suggestions?

Forum Responses

(Cabinetmaking Forum)

From contributor W:

Is the office piece going to be painted or stained?

From the original questioner:

It’s going to be finished with lacquer.

From contributor L:

You can put horizontal batons on the back side to prevent cupping, but it won't prevent warping or twisting. That depends on the stability of your wood. I would suggest using a veneered plywood (plain slice) and gluing an edge on for routing.

From the original questioner:

To contributor L: I thought of that, but then there would be a glue line and the client wants a clean look. I may have to talk him out of the rounded edge.

From contributor P:

I would suggest using MDF with oversized hard wood frame. Then cut the MDF biscuit and frame around it using epoxy and butt joints. Drum sand it so everything is the same thickness and veneer over MDF and hard wood on both sides. Then cut door to size and router the edge.

You can use mitered lap joints if don’t want to see a butt joint, and I have used tongue and groove joints to joint the hard wood to the MDF. I recommend ¼ cut hard wood. It is more stable, and the grain picture in the edge is less eye catching. When using veneer, it is easier to match all the doors and draw fronts. I would suggest not using paperbacked veneer, the paper will show when you cut the edge.

From contributor S:

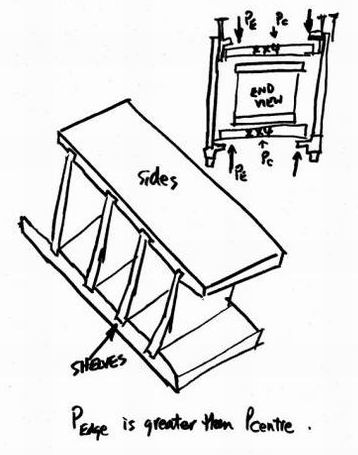

Contributor P's suggestion is a good one. If you don't have the means to do the veneering, I would suggest using quarter sawn material and this will minimize warping/winding etc. There are a few standard ways to keep solid wood flat: Breadboard ends are fairly standard as well as battons on the backs of the doors.

I have also routed two sliding dovetails into the doors that flush out with the back of the doors. This is the cleanest, but it is very time consuming and you have to make sure that the dovetail actually is able to let the wood move. (Don't glue it in. If that is too time consuming, then use quarter sawn material and attach two battons on the back and make sure to oval the holes in the batton to allow the wood to move.

From contributor J:

Is this door going to be inset or full overlay that will be close to other doors, drawers, etc? If so, I would also be worried about expansion with climate changes. When I put battens on slab doors, I will drill oversize holes. Make sure to not glue the battens to the door - this will allow the door to move. Using quarter sawn lumber will also help control the expansion - as common practice I also alternate the grain when gluing up the panels.

From Gene Wengert, forum technical advisor:

Wooden doors do not warp unless their moisture changes. So, use several coats of finish on all six sides; this will retard moisture changes. Also, have them specify the in-use RH (maybe wintertime and summertime). You then convert that to in-use moisture content and use the lower value for your manufacturing moisture content. Wrap the doors in plastic to prevent any moisture change after manufacturing and before they are installed. If you minimize moisture changes, you minimize warping risks.

From contributor M:

To the original questioner: Contributor S's suggestion of sandwiching a hardwood edged MDF panel between two layers of veneer is a bullet proof solution to your problem and will yield a door which looks perfect. I do this a lot, and find that you don't even have to use a reinforced joint (biscuits, etc.) to attach the hardwood edging to the panel before veneering if you use paperbacked veneer.

The paperback veneer is strong enough to reinforce the joint even if just contact cemented down.

Contributor S is right that the paper could show if it is not reasonably of the same color as the wood.