Question

(WOODWEB Member):

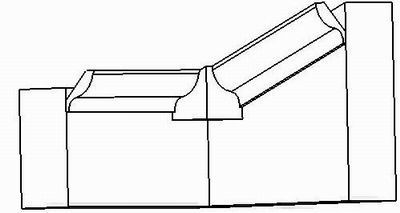

I am an experienced cabinetmaker who recently started a job at a new shop. There is a material core that I have seen in the past, but at this shop it is the standard for almost everything from cabinet doors and open cabinetry to countertops and structural pieces. The shorthand name in the shop is "cross-band." It is a plywood and MDF composite with 3/8" plywood core, with 5/32" MDF on each side, resulting in a 11/16" material. Does anyone here use it on a regular basis? It seems an expensive material for how we are using it.

I searched the websites of the larger manufacturers but could not find anything, other than that they offer it as a material core, not in the raw as we have it in the shop. I have contacted our supplier in regards to WHIMIS and MSDS sheets, as I have a contract that has asked for this information.

Do you build and laminate with this product or have you just ordered veneered/laminated panels with it as the core (how I have seen it in the past)?

Forum Responses

(Architectural Woodworking Forum)

From contributor M:

I've never used it but I have seen it referred to as combination core. Crossband is more of the orientation used in laying up. There are several different core options that use crossbanding. The info I have seen refers to lighter weight as compared to an MDF or PB core, screw holding, and flatness. I'm not sure how the flatness figures in. No idea on the cost.